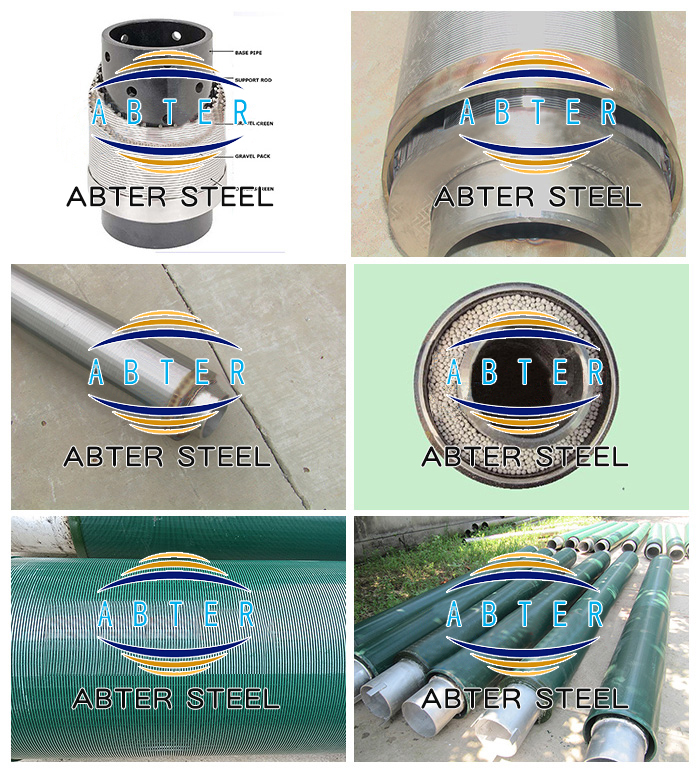

Double-layer lined screening pipe&Sand-control screening pipe for oil well

April 25, 2022

Examples of steel pipe pile construction methods

May 19, 20221 Overview

For more than half a century, steel pipe piles have gradually become one of the main types of piles in foundation engineering. Steel pipe piles are widely used in Shanghai, my country, and some deep-water wharves, Baoshan iron and steel plants, power plants and dozens of high-rise buildings are all based on steel pipe piles. 2 Advantages and disadvantages of steel pipe piles

(1) Advantages: Good driving resistance, that is, it can withstand a strong impact force when it is driven into the soil, has a strong ability to penetrate the hard soil layer, and can effectively drive into the hard pile end bearing layer, so it can be expected to obtain a considerable The vertical bearing capacity is suitable for foundation piles of tall, heavy, large and construction (structure) buildings; ②The horizontal bearing capacity is large, suitable for construction (structure) subjected to horizontal forces such as earthquake force, wave force and earth pressure. The foundation piles of buildings; ③ There are many types of outer diameters and wall thicknesses, so it is convenient to choose the appropriate pile size; ④ From the construction point of view, it is easy to change the pile length according to the different bearing layers of the pile ends, and the reliability of on-site welding is high. The pile foundation is easy to connect with the superstructure, and the amount of soil squeezed by the open pile is less, so it will not have adverse effects on the adjacent existing buildings;

(2) The disadvantage is high cost; ② It is not economical when used as a short friction pile or a pile that does not bear horizontal force; ③ When the hammer-type pile driving is used, the noise and vibration are high; ④ When the large diameter open pile is used , the occlusion effect is not good enough.

2 Steel pipe pile construction method

2.1 Classification and characteristics of steel pipe pile construction methods

Steel pipe pile construction methods can be divided into three categories: driven pile construction method, buried pile construction method and pressed pile construction method, and there are more than 20 kinds of subdivisions. Characteristics of steel pipe pile construction method (see Table 1)

2.2 Selection principle of steel pipe pile construction method

When choosing the construction method of steel pipe piles, consideration should be given to: the requirements of the building; ② the environmental conditions of the construction site; ③ the hydrogeological conditions of the construction stratum; Whether the selected construction method has soil drainage or mud sewage treatment, etc.

3 steel pipe specifications

3.1 Classification of steel pipes

Steel pipes can be divided into two categories: seamless steel pipes and welded steel pipes. The commonly used steel pipe piles are electric-welded steel pipes, of which spiral steel pipes account for the majority; high-frequency resistance-welded steel pipes are only used for small diameter steel pipe piles (outer diameter below 609.6mm, wall thickness below 16mm); U.O.E. steel pipes and coiled steel pipes Used for steel pipe piles with larger diameters or larger wall thicknesses. The dimensions and characteristics of various steel pipes are shown in Table 2.

3.2 For the dimensions, quality and tolerances of single-section steel pipes, see Reference [1].