What is the difference between pipe vs tube?

August 17, 2018

How to calculate the pressure capacity of seamless steel pipe

September 27, 2018Methods for preparation and construction of protective coatings for petroleum pipelines

[57] Abstract

The invention provides a protective coating for oil pipes and wellheads and downhole equipment used in oil and gas drilling, oil recovery and transportation. The protective coating comprises, by weight percentage, 55 to 95% of polyphenylene sulfide, 3 to 30% of adhesion enhancer, and 1 to 20% of abrasion resistant enhancer. A surface wettability converting agent may also be included in the range of 1 to 15%. It can prevent or reduce the high temperature, high pressure, high hydrogen sulfide and carbon dioxide, high salt content and other strong corrosive media on the erosion, corrosion and waxing, scaling and hydrate blockage, reduce friction and reduce production costs. Improve the overall performance and service life of oil pipes. The present invention also provides a method of preparing such a protective coating and a method of constructing the same.

1. Protective coating for petroleum pipes, characterized in that the weight percentage comprises the following components:

55~95%, 3~30%,

1 to 20%.

Polyphenylene sulfide adhesion enhancer

2. The protective coating for petroleum pipes according to claim 1, wherein the adhesion enhancer is at least one of micron or nanometer titanium dioxide, chromium trioxide, cobalt sulphate, and carbon fiber. The wear-resistant enhancer is at least one of micron or nano-sized aluminum oxide, copper sulfide, silicon carbide, molybdenum disulfide, carbon fiber, and silicon dioxide.

A protective coating for petroleum pipes according to claim 1 or 2, which comprises the following components in percentage by weight:

Polyphenylene sulfide 55~95%,

Adhesion enhancer 3~30%,

Wear-resistant enhancer 1~20%,

Surface wettability conversion agent 1~15%.

A protective coating for petroleum pipes according to claim 3, wherein the surface wettability converter is at least one of fluorine tetrahexa, polytetrafluoroethylene, polyvinyl alcohol, and molybdenum disulfide.

5. A protective coating for petroleum pipes according to claim 3, characterized in that the following components are included by weight:

Polyphenylene sulfide 55~95%,

Adhesion enhancer 3~30%,

Wear-resistant enhancer 1~20%,

Surface wettability conversion agent 1~15%,

Surface leveling agent 0• 5~5%.

A protective coating for petroleum pipes according to claim 5, wherein the surface leveling agent is at least one of titanium oxide, silane, and octyl acrylate copolymer of the order of micrometers or nanometers.

A protective coating for petroleum pipes according to claim 1 or 2, characterized in that the following components are included in percentage by weight:

Polyphenylene sulfide 55~95%,

Adhesion enhancer 3~30%,

Wear-resistant enhancer 1~20%,

Surface leveling agent 0. 5~5%.

A protective coating for petroleum pipes according to claim 7, wherein the surface leveling agent is at least one of micron- or nano-sized titanium dioxide, silane, and octyl acrylate copolymer.

9. A method for preparing a protective coating for a petroleum pipe, characterized in that the method comprises ball-milling polyphenylene sulfide powder with other components and ethanol of 3 to 5 times the weight of polyphenylene sulfide in a ball mill, time For 4~24 hours, after ball milling, the particle size is controlled at 0.074~0.096 mm, and the suspension of protective coating is prepared for use; then the suspension is dried at 11 CTC ~ 160 ° C for 4-6 hours, ie A dry powder of protective coating is obtained.

10. A method of constructing a protective coating for a petroleum pipe, characterized in that the method comprises the following steps:

1), the surface of the workpiece is pretreated: the cover on the surface of the workpiece is removed;

2), spraying with high pressure airless spraying or electrostatic powder spraying process;

a ) High pressure airless spraying with a suspension of protective coating: spraying on the workpiece in a high pressure and airless manner or spraying the bottom layer, the top layer and/or the intermediate layer on the workpiece: first spraying the bottom layer on the workpiece, the spraying ends after the workpiece into [deg.] 60~80 C oven for 20 to 30 minutes of pre-baked in full removal of solvent the bottom, and then into the plasticized workpiece plasticizing furnace, plasticizing temperature is [deg.] 300~350 C , The plasticizing time is 15~60 minutes; the thermal spraying process is adopted for the middle layer and the surface layer, that is, the workpiece is taken out from the plasticizing furnace, and the upper layer or the surface layer is quickly sprayed, respectively, and then plasticized in a plasticizing furnace. The plasticizing temperature is 320 ° C ~ 400 ° C , the plasticizing time is 30 ~ 120 minutes, and finally the plasticized workpiece coated with the surface layer is taken out of the furnace and immediately placed in water to be cooled and quenched;

b ), using dry powder of protective coating on the workpiece once or on the bottom layer, the surface layer and / or the intermediate layer for electrostatic powder coating. • Is the use of high-voltage electric field effect, the coating powder is negatively charged, the workpiece is grounded, so that the paint is absorbed into the workpiece On the surface, the workpiece is attached with powder coating and then sent to the plasticizing furnace. The powder is melted by heat and leveled and solidified into a film. The thickness of the bottom layer is 30~100^〇1, and the plasticizing temperature is 300!:~350°(: The plasticizing time is 15~60 minutes, the plasticizing temperature of the middle layer or the surface layer is 320° C ~400° C , the plasticizing time is 30 ~ 120 minutes, and finally the plasticized workpiece is quickly taken out from the furnace. Put in water to cool and quench.

Protective coating for petroleum pipe, preparation method and construction method thereof

Technical field:

The invention relates to a petroleum pipe used in oil and gas drilling, oil recovery and transportation, a protective coating for a wellhead and a downhole equipment, a preparation method thereof and a construction method.

Background technique:

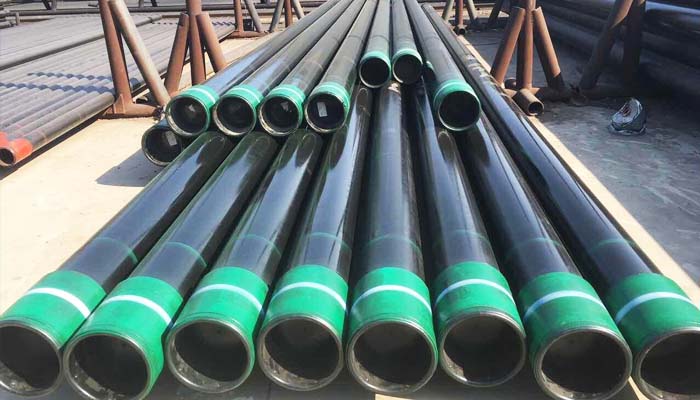

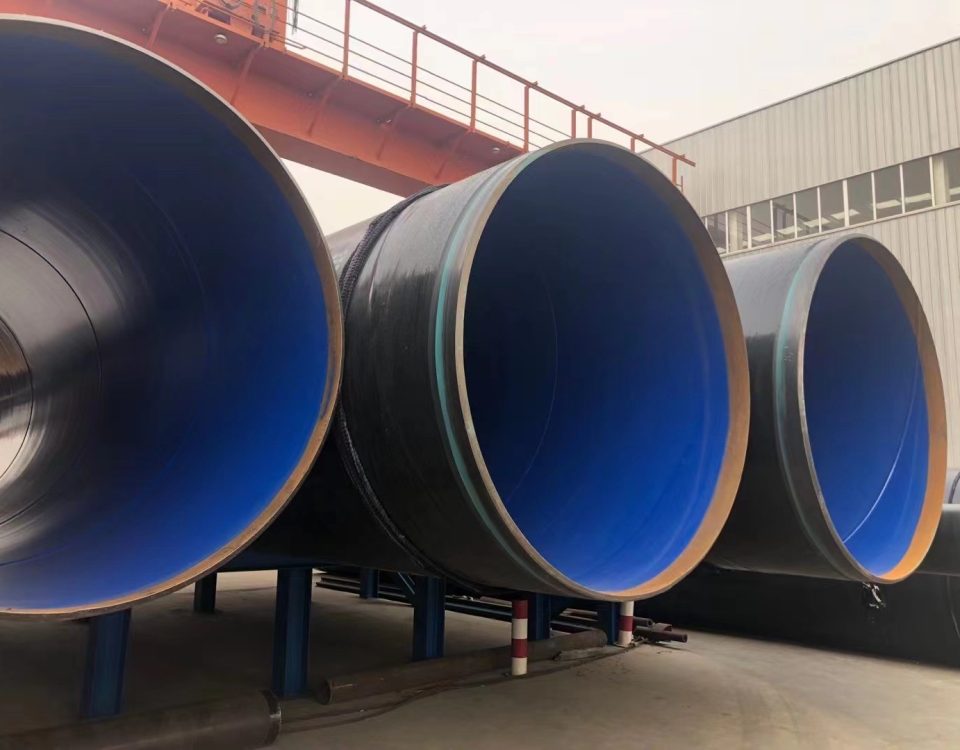

Oil pipes include drill pipes, tubing, casing and oil and gas pipelines and sucker rods. Downhole and wellhead equipment includes wellhead high pressure control systems, station equipment and downhole pumps and packers. The working environment of oil pipelines and wellheads and downhole equipment is very harsh (such as oil and gas wells may be as high as 180 ° C , pressures may be as high as 100 MPa , high concentrations of hydrogen sulfide and carbon dioxide, high chloride content and other highly corrosive media), and their service life and Performance has seriously affected exploration and development and oil and gas field operations. For sulfur-containing gas fields, it may cause environmental problems and major safety accidents.

At present, the methods used in the protection of petroleum pipelines are mainly: stainless steel pipes are used in harsh corrosive environments, but stainless steel is expensive, and its use conditions are also limited. It is necessary to adapt to the temperature, carbon dioxide, hydrogen sulfide and chloride content. Steel type. For oil and gas wells with temperatures below 100 ° C , epoxy phenolic series coatings or linings are mainly used at home and abroad. The main problem with these coatings is temperature sensitivity, and their overall performance is reduced at temperatures above 100 ° C. The applicant entrusted the authoritative organization of China’s petroleum industry to conduct high-temperature and high-pressure harsh environmental corrosion evaluation test (the test standard adopts the American Society of Corrosion Engineers Standard NACE TM 0185-93 “Test Method for Autoclave Evaluation of Tube Plastic Internal Coating Anticorrosion”), and found the above. The coating is soaked in a harsh corrosive environment of the oil pipe (ie, high temperature (140 ° C ), high pressure (35 MPa ), high hydrogen sulfide and carbon dioxide, high chloride content, high salt content and other strong corrosive media) The coating is bubbling and delaminating. Analysis of the reason found that: when implemented by the method described above, the adhesion of the coating to the petroleum pipe matrix is poor, and the coating becomes brittle. When the temperature is higher than 14 ( TC) , the reliability of the overall performance is lowered, and the range of use is limited.

Chinese Patent Application Publication No. 1100124 A “High-temperature anti-stick anti-corrosion coating” discloses a coating based on polyphenylene sulfide, which can be used in a rubber mold and a reaction kettle, and has a certain non-stickiness. China Patent Application Publication No. 1100123 A “Abrasion Resistant Coating” discloses a wear-resistant anti-wear coating which has good thermal stability, chemical resistance, mechanical properties, adhesion, self-lubricity and resistance. Grindability can be applied to parts of various mechanical products in mining, metallurgy, building materials, energy, agricultural machinery, transportation and other departments. in

National Patent Application Publication No. 1133331 A “Polyphenylene sulfide resin anticorrosive coating” discloses a polyphenylene sulfide resin anticorrosive coating for use in a coal tar kettle of a coking plant, which is used for spraying on carbon due to acid and alkali resistance. On the inner surface of the coal tar kettle made of steel plate, plasticized to form a protective layer to meet the process requirements of the kettle. China Patent Application Publication No. 1 253 979 A “A heat-resistant, acid-resistant coating for the surface of a metal material” discloses a heat-resistant and acid-resistant coating for the surface of a metal material, and the metal material treated by the invention is at a high temperature and a high concentration. Sulfuric acid has good corrosion resistance in the harsh environment.

At present, the anti-corrosion coatings for petroleum pipes (sweat, oil pipes, etc.) of China’s petroleum industry are mainly imported, and the coatings are epoxy phenolic.

Summary of the invention:

The object of the present invention is to provide a method for preventing or reducing high temperature, high pressure, high hydrogen sulfide and carbon dioxide, high salt and other strong corrosive media to corrode and wax, scale and hydrate the pipeline, and improve the oil pipe. Anti-corrosion, anti-wear, anti-erosion, anti-foling, anti-fouling, anti-friction, reduce production costs, improve the overall performance and service life of oil pipes, protective coatings for oil pipes and wellheads or downhole equipment . Another object of the invention is to provide a process for the preparation of such protective coatings. Still another object of the present invention is to provide a method of construction of such a protective coating.

The object of the invention is achieved in this way:

The protective coating for petroleum pipes of the present invention is characterized by comprising the following components in percentage by weight:

Polyphenylene sulfide 55~95%,

Adhesion enhancer 3~30%,

Wear-resistant enhancer 1~20%.

The above adhesion enhancer is at least one of micron or nanometer titanium dioxide ( Ti 0 2 ), chromium oxide ( Cr 2 0,), cobalt oxychloride ( C 〇2 0 3 ), carbon fiber, and is resistant to The abrasive enhancer is at least micron or nanometer aluminum oxide ( A 1 2 0 3 ), copper sulfide ( CuS ), silicon carbide ( SiC ), molybdenum disulfide ( MoS 2 ), carbon fiber, silica Alternatively, other adhesion enhancers or abrasion enhancers may be employed.

The above protective coatings include the following components by weight.

|

Polyphenylene sulfide |

55~95%, |

|

Adhesion enhancer |

3 to 30%, |

|

Wear-resistant enhancer |

1 to 20%, |

|

Surface wettability converter |

1 to 15%. |

The above surface wettability conversion agent is at least one of fluorine tetrahexene ( F #), polytetrafluoroethylene, polyvinyl alcohol, molybdenum disulfide ( M 〇 S 2 ), and other surface wettability conversion may be employed. Agent.

The above protective coatings include the following components by weight:

|

Polyphenylene sulfide |

55~95%, |

|

Adhesion enhancer |

3 to 30%, |

|

Wear-resistant enhancer |

Bu 20%, |

|

Surface wettability converter |

1 to 15%, |

|

Surface leveling agent |

0. 5~5%. |

The above surface leveling agent is at least one of micron or nanometer titanium dioxide, silane, and octyl acrylate copolymer, and other surface leveling agents may also be used.

The above protective coatings include the following components by weight:

Polyphenylene sulfide 55~95%,

Adhesion enhancer 3~30%,

Wear-resistant enhancer 1~20%,

Surface leveling agent 0.5~5%.

The above surface leveling agent is at least micron or nanometer titanium dioxide, silane, octyl acrylate copolymer

One of them.

The protective coating for petroleum pipeline of the present invention is prepared by putting a polyphenylene sulfide powder and other components and ethanol of 3 to 5 times the weight of polyphenylene sulfide into a ball mill for ball milling for 4 to 24 hours. After ball milling, the particle size is controlled to be 0.074~0.096 mm, and the suspension of the protective coating is prepared for use; and the suspension is dried at a temperature of 1 HTC to 160 ° C for 4 to 6 hours to obtain a dry powder of the protective coating.

The method for constructing a protective coating for petroleum pipes of the present invention comprises the following steps:

1), the surface of the workpiece is pretreated: the cover on the surface of the workpiece is removed;

2), spraying with high pressure airless spraying process or electrostatic powder spraying process;

a ), using a protective coating suspension for high-pressure airless spraying: spraying on the workpiece in a high-pressure airless manner or spraying the bottom layer, the surface layer and/or the intermediate layer on the workpiece; first spraying the bottom layer on the workpiece/after spraying , [deg.] the workpiece into 60~80 C oven for 20 to 30 minutes in the prebaking, the solvent is removed fully underlying the workpiece is then fed into the furnace plasticized plasticized, [deg.] plasticizing temperature of 300~350 C , plastic The time is 15~60 minutes; the middle layer and the surface layer are all sprayed by thermal spraying process, that is, the workpiece is taken out from the plasticizing furnace, and the upper layer or the surface layer is quickly sprayed separately, and then plasticized in a plasticizing furnace, plasticized The temperature is 320 ° C ~ 400 ° C , the plasticizing time is 30 ~ 120 minutes. Finally, the plasticized workpiece coated with the surface layer is taken out from the furnace and then rapidly quenched by water cooling, spraying the middle layer or the surface layer. The number of times depends on the thickness of the coating required for corrosion protection;

b ), using protective coating dry powder on the workpiece once or in the bottom layer, the surface layer and / or the intermediate layer for electrostatic powder coating; using the high-voltage electric field induction effect, the coating powder is negatively charged, the workpiece is grounded, so that the coating powder is adsorbed onto the surface of the workpiece, The workpiece is attached with powder coating and then sent to the plasticizing furnace. The powder is melted by heat and leveled and solidified into a film. The thickness of the bottom layer is 30 ~ 100 nm, the plasticizing temperature is 300 ° C ~ 350 ° C , and the plasticizing time is 15~ 60 minutes, the plasticizing temperature of the middle layer and the top layer is 320 ° C ~ 400 ° C , the plasticizing time is 30 ~ 120 minutes. Finally, the plasticized workpiece is taken out of the furnace and quickly placed in water to cool and quench. The number of intermediate layers or top layers depends on the thickness of the coating required for corrosion protection.

The invention uses polyphenylene sulfide as a base material to improve the protection performance of the oil pipe by adding certain modified materials. The most commonly used modifier is titanium dioxide, which smoothes the surface of the coating, reduces pinholes, and improves adhesion. The addition of graphite improves the lubricity of the coating. Adding Cr 2 0 : P Co 2 0 : i , MoSy and other cobalt or molybdenum sulfide or oxide can color the coating, can also promote plasticization, improve the adhesion and mechanical properties of the coating, and increase the hardness of the coating itself. , wear resistance, reduce the friction coefficient of the surface, the corrosion resistance of the coating is good, and the comprehensive performance of the coating under high temperature and high pressure conditions is enhanced. The addition of carbon fiber greatly improves its wear and abrasion resistance. The simultaneous addition of carbon fiber and M 〇 S 2 has a synergistic effect, which can greatly enhance the wear resistance of the coating. Add fluorotetracycline, polytetrafluoroethylene, etc. to change the surface energy and wettability of the coating surface, so that crude oil, water and salt can not adhere to the surface of the coating (with eucalyptus and hydrophobicity), to achieve anti-fouling, The purpose of waxing. Silane and octyl acrylate copolymers are also very effective for surface leveling.

The protective coating of the invention is a novel protective coating for petroleum pipes with good thermal stability, corrosion resistance, softness, hardness, gloss, elongation, impact resistance, abrasion resistance, adhesion and self-lubrication, The performance characteristics are as follows:

(1) Good heat resistance. [Deg.] Long-term use temperature of up to 170-200 C , ultra high temperature short time [deg.] Up to 270 C .

(2) Good chemical resistance. It is resistant to strong corrosion by acids, alkalis, salts and various solvents, and there are no problems such as chloride stress corrosion cracking which is difficult for most stainless steels to withstand.

(3) Compared with the most advanced epoxy phenolic series at home and abroad, the protective coatings of the present invention have higher performances against high temperature, erosion, aging, and harsh environmental corrosion than the epoxy phenolic series coatings commonly used at home and abroad. .

(4) Excellent mechanical properties, good flexibility, impact resistance, wear resistance, and strong adhesion to metal walls. It has been evaluated that the erosion resistance is about 5-10 times higher than that of imported epoxy phenolic paint, which is very suitable for use in natural gas flow corrosion and erosion. The wear resistance is outstanding, and the addition of certain modified materials can greatly improve the wear resistance.

(5) It can be modified to have certain characteristics according to the actual working conditions: low friction resistance, used to reduce the flow resistance in the oil pipe and inside the conveying pipe; high strength and high erosion resistance, used in wellhead equipment; Sex and double sex

(Oyster oil is water-repellent), which can change the surface wettability of the coating, and is good for preventing waxing and scaling. In order to improve the compactness of the coating, the addition of nano-sized modifiers and/or reinforcing agents will make the binding force with polyphenylene sulfide closer, which is beneficial to prevent the penetration of sulfide oxygen. Spraying the coating of the invention on the inner wall of the oil pipeline can reduce the surface of the tube wall

Free energy can reduce the roughness of the surface of the pipe wall, reduce the friction loss, and achieve the purpose of anti-wax, anti-fouling and drag reduction.

(6) Repairability: The leakage point of the coating and the damage occurring during use can be repaired, but the epoxy phenolic paint does not have this feature.

The features of the protective coating of the present invention are:

1. Comprehensive protection of the protective coating of the invention under high temperature and high pressure conditions

(1) Comprehensive protection test equipment and standards adopted

The comprehensive protective performance evaluation of the coating materials was carried out by the American Society of Corrosion Engineers Standard NACE TM0185 – 93 “Test Method for Evaluation of Autoclaves for Tube Plastic Inner Coating Anticorrosion” to evaluate the protective effect of the coating on the metal. The test vessel exposes the workpiece to a corrosive medium environment, and the overall protective performance of the coating under specific environmental conditions is evaluated by changes in the coating and the corrosive medium under high temperature and high pressure conditions.

(2) High temperature and high pressure comprehensive protection test 1

Test conditions: chloride content of 15 X- 10 . 4 PPM , the PH = 5.0, test pressure: 34 is ± lMPa , carbon dioxide partial pressure P two 3.51 = ^ \ ^^, [deg.] Test temperature of 150 C . Test time: 3 hours of heating time, 5 hours of cooling time, and 231 hours of effective experiment time, totaling 239 hours (about 10 days).

Epoxy phenolic coating test results: under the high temperature and high pressure corrosion test conditions of 150 °C , the coating is severely bubbling, and the coating itself is poor in corrosion resistance. Ceramsite series coating test results: almost all of the coating peeled off and became brittle. The test results of the protective coating of the present invention: the coating is intact and not damaged, and has high corrosion resistance and excellent comprehensive protection performance.

(3) High temperature and high pressure comprehensive protection test II

It is basically the same as the above high temperature and high pressure comprehensive protection test. Only the temperature is lowered to 120 ° C, hydrogen sulfide is added, and the partial pressure of hydrogen sulfide : P5i tta = 1.6 MPa (5%), test time : 9 days.

Epoxy phenolic coating test results: the coating has no corrosion marks and good performance. Ceramsite series coating test results: there are dense vesicles with slight variations in color. The test result of the protective coating of the invention has no change in the color and gloss of the coating, the interface coating at the metal cutting portion is not damaged, the mechanical cutting portion does not cause the coating to loosen and peel, and the coating has high corrosion resistance and excellent comprehensiveness. Protective performance.

(4) High temperature and high pressure comprehensive protection test III

Test time: 212 hours, pressure: 31~32 MPa , temperature: 100 ° C , partial pressure of hydrogen sulfide = 6.5 MPa (5? 4), partial pressure of carbon dioxide Pk seven pull = 3.2 Mpa , content of chloride content 15 X 10 4 PPM , PH = 5.0〇

Test result of protective coating of the invention: the coating is not damaged, has high corrosion resistance and excellent synthesis

Protective performance.

(5) High temperature and high pressure anti-fouling test

The autoclave test was carried out by simulating the corrosion environment in a well. Test time: 168 hours; pressure: 35 MPa ; temperature: 120 ° C ; carbon dioxide partial pressure P x 7 lM = 3.5 Mpa , chloride content CIT : 10 X 10 4 PPM , PH = 5.5 .

The test result of the protective coating of the invention: the coating was not damaged, the adhesion was good, and the test was successful. The blank sample which was not sprayed with the protective coating of the present invention was very corroded and a layer of calcium carbonate was formed. The test piece using the protective coating of the present invention showed no signs of corrosion and had no calcium carbonate scale on the surface.

(6) Anti-sulfide stress corrosion cracking test

Test Purpose: To test whether the coating will cause microcracking or delamination under the tensile stress condition of 80% steel yield limit. The coating is tested for its resistance to hydrogen sulfide hydrogen embrittlement, i.e., resistance to hydrogen atom penetration. If the coating is broken, the contact of hydrogen sulfide with the steel will quickly cause the sample to break.

Test results: Two tubes of N 80 without any treatment were pulled off within 4 hours. The sample using the protective coating of the present invention was not broken for 720 hours. The novel protective coating of the invention has strong anti-hydrogen sulfide hydrogen embrittlement ability and is suitable for the harsh corrosive environment with high hydrogen sulfide and carbon dioxide.

2. Wear resistance

The test standard for falling sand abrasion resistance is SY/T 0315-97. Epoxy phenolic coating falling sand abrasion resistance test result 5.4 L / um ; ceramsite series coating falling sand abrasion resistance test result 6.2 L / lim ; protective coating falling sand of the invention abrasion resistance test result 40.0 L / ym . The protective coating of the invention has high wear resistance and is suitable for gas wells with high erosion resistance.

3. Impact resistance

The impact test standard is SY/T 0315-97. Epoxy phenolic coating impact resistance (1.5 J ): pass; ceramsite series coating impact resistance (1.5 J ): pass; protective coating of the invention impact resistance (1.5 J ): pass.

4. Adhesion

The adhesion test standard was SY/T 0315-97. This protective coating has a adhesion rating of 1.

5. Appearance

Visually, it was found to be uniform in color and smooth.

The protective coating of the present invention is based on polyphenylene sulfide ( PPS ), and various organic or inorganic micro or nano modifiers are added for different applications and performance requirements. The present invention is a thermoplastic material that can be used to repair coating defects or damage points. The invention aims at the actual situation that the oil and gas well waxing and scaling seriously affect the normal production of the oil and gas field, and the protective coating of the invention can change the wettability of the pipe wall to achieve the purpose of preventing waxing, scaling and hydrate blockage.

In the comprehensive performance evaluation experiment, the protective coating of the invention has proved that its resistance to high temperature, corrosion resistance and erosion resistance is much higher than that of epoxy phenolic series, fluorocarbon and the like, which can significantly improve the service life of the oil pipe and performance, long-term working temperature up to ° 170~200 C . Compared with protective coatings imported from abroad, the cost of the protective coating of the present invention is greatly reduced.

The preparation method of the protective coating of the invention is simple. The construction method of the protective coating of the invention can coat the petroleum pipe, the oil wellhead or the downhole equipment with the protective coating of the invention to ensure the quality of the coating.

detailed description:

Example 1:

The protective coating of the present invention is composed of the following raw materials by weight:

Polyphenylene sulfide ( PSS ) 65%

Chromium trioxide ( Cr 2 0 3 ) 5%

Titanium dioxide ( Ti 0 2 ) 15%

Silicon carbide ( SiC ) 14%

Silane 1 %

The above materials are all micron-sized materials.

Main application: high hardness, high wear resistance, smooth surface, no pinholes, used for inner coating of drill pipe, high-yield gas well pipe inner coating.

The preparation method of the protective coating of this embodiment is:

(1) A polyphenylene sulfide powder and the above reinforcing agent and ethanol having a weight of 5 times the weight of polyphenylene sulfide were placed in a ball mill for ball milling.

(2) Using a ceramic ball mill, the ball milling time is 12 hours.

(3) After sieving, the particle size of the powder is less than 0.096 mm , and the suspension of the protective coating is prepared for use.

The construction method of the protective coating of this embodiment is:

1, workpiece surface pretreatment

The coating is removed by removing the paint on the surface of the oil pipe by mechanical sintering, and the rusting is performed by mechanical blasting to increase the bonding strength between the coating and the workpiece, and to improve the overall performance of the coating.

2, high pressure airless spraying, plasticizing process:

The spraying and plasticizing process of the bottom layer:

The bottom layer was sprayed by a high-pressure airless method, and then the workpiece was placed in an oven at 80 ° C for 30 minutes, and the solvent in the suspension paint was dried and plasticized. The plasticizing temperature is 320 ° C and the plasticizing time is 30 minutes. Spraying and plasticizing process of intermediate layer and surface layer

(1) The middle layer is thermally sprayed. The workpiece was taken out of the furnace, sprayed quickly, and then plasticized at a temperature of 320 ° C for 30 minutes.

(2) For the top layer, the plasticizing temperature is 34 ( TC , plasticizing time is 60 minutes. Finally, after the plasticized workpiece is taken out of the furnace, it is quickly placed in the prepared cooling water and rapidly cooled (quenched).

Coating quality inspection and control

After the plasticization is completed, the following indicators need to be tested:

(1) Measurement of coating thickness by coating thickness gauge: Magnetic thickness gauge Mikrotest – F 6

(2) Using a spark detector to detect the presence of pinholes in the coating: using LCD -3 type DC spark detection

Measuring instrument

(3) Measuring the hardness of the coating using a hardness tester: GB 6739-86 hardness tester;

(4) Measuring the impact strength of the coating with an impact tester; GB 1732-79 impact tester;

(5) Determination of adhesion level of coating by adhesion meter: GB 9286-88 adhesion tester;

(6) The erosion resistance of the coating is tested by a falling sand abrasion tester : SY / T 0315-97;

Example 2:

The protective coating of the second embodiment is composed of the following components in percentage by weight:

Polyphenylene sulfide ( PSS ) 80%

Cobalt trioxide (nanoscale) 5%

Titanium dioxide (nanoscale) 10%

Al2O3 (nanoscale) 5%.

Main application: • High abrasion resistance, smooth surface, no pinholes, used for the downhole oil pipe of the harsh environment (including hydrogen sulfide), the inner coating of the conveying pipe.

The construction method of the protective coating of the second embodiment adopts an electrostatic powder spraying process, and the powder preparation process is as follows. The ball-milled suspension is placed in an oven and baked at ll 〇 ° C for 6 hours. Control powder particles with a DC of less than 0.074 mm . The method is a coating method in which a powder is adsorbed onto a surface of a workpiece by utilizing a high-voltage electric field induction effect. Then the workpiece is sent to the baking furnace, and the powder is melted by heat and leveled and solidified by crosslinking.

membrane.

Underlying spraying and plasticizing process

The thickness of the bottom layer should be less than 60 um , the plasticizing temperature is 320 ° C , and the plasticizing time is 30 minutes.

Surface coating and plasticizing process

Place the workpiece in a dust cover, stop spraying when the sprayed powder is no longer melted, and a layer of powdery material appears on the workpiece, then quickly put it into the plasticizing furnace to plasticize it and cycle it twice until it is required. The coating thickness is 150~250 um . The plasticizing temperature was 340 ° C and the plasticizing time was 60 minutes.

Finally, the plasticized workpiece is taken out of the furnace, quickly placed in the prepared cooling water, and rapidly cooled (quenched)

fire).

The oil pipe belongs to the slender pipe. For example, the 2 7/8” oil pipe used in the petroleum industry has an inner diameter of 60 mm and a pipe length of 9.6 m . The protective coating of the invention has a high melting point and a high plasticizing temperature, and is currently not sprayable in China. The invention discloses a device and a technology for protecting a coating powder to a petroleum pipe. In order to ensure uniform thickness of the coating, no pinholes, and a smooth surface, a self-developed MPS – P powder coating system is adopted . The system utilizes information technology and an automatic control system. Realize computer automatic monitoring and spraying. MPS – P powder coating system controls the running track and temperature distribution of the intermediate frequency electromagnetic local heating system, controls the running track of the powder gun, and ensures that the powder can be sprayed evenly, quickly and spirally to the slender oil. The inner wall of the pipe controls the running speed of the oil pipe and sends the oil pipe to the natural gas plasticizing furnace for plasticization. The natural gas plasticizing furnace should make the temperature distribution of each part of the slender oil pipe uniform to ensure the coating quality.

Example 3:

The protective coating of the third embodiment is composed of the following raw materials by weight:

Polyphenylene sulfide ( PSS ) 60%

Fluorine tetras ( F 4fi ) 10%

Chromium trioxide ( Cr 2 0 3 ) 5%

Titanium dioxide ( Ti 0 2 ) 15%

Silicon carbide ( SiC ) 10%

The above materials are all micron-sized materials.

Main application: high hardness, high anti-wear, anti-wax and scale of petroleum pipe, inner coating of downhole oil pipe and conveying pipe used in harsh environment.

The preparation method and construction method of the protective coating of the third embodiment are the same as those of the first embodiment.

Example 4:

This embodiment 4 consists of the following components in percentage by weight:

Polyphenylene sulfide ( PSS ) 57%

Polytetrafluoroethylene ( F 4 ) 10%

Cobalt trioxide ( Co 2 0:,) 5%

Titanium dioxide ( Ti 0 2 ) 25%

Carbon fiber 3%

The above materials are all micron-sized materials.

Main application. • Prevent oil pipe from waxing, scaling, smooth surface, good adhesion and low friction coefficient.

The preparation method and construction method of the protective coating of the fourth embodiment are the same as those of the second embodiment.

The above-mentioned embodiments are further described in the above description of the present invention, but the scope of the above-mentioned subject matter of the present invention should not be construed as being limited to the above embodiments. Any technology implemented based on the above is within the scope of the present invention.