EN10210 Hollow Section for Structural | Square rectangular steel pipe

December 7, 2023

DUPLEX STEEL 2205 PIPE | UNS S31803 PIPE

December 12, 2023UNS N06200, commonly known as Hastelloy C-2000, is a nickel-chromium-molybdenum alloy designed to offer an improved resistance to aggressive forms of corrosion. This particular alloy is part of the Hastelloy family, which is well-known for its high resistance to corrosion in a wide range of chemical environments.

Composition of Hastelloy C-2000 (UNS N06200):

The chemical composition of Hastelloy C-2000 typically includes:

- Nickel (Ni): Balance

- Chromium (Cr): 22-24%

- Molybdenum (Mo): 15-17%

- Copper (Cu): 1.3-1.9%

- Iron (Fe): 3% maximum

- Manganese (Mn): 0.50% maximum

- Silicon (Si): 0.08% maximum

- Carbon (C): 0.01% maximum

- Vanadium (V): 0.35% maximum

- Phosphorus (P): 0.025% maximum

- Sulfur (S): 0.02% maximum

Properties of Hastelloy C-2000:

- Excellent corrosion resistance: It has outstanding resistance to a wide variety of chemical process environments, including hot contaminated mineral acids, solvents, chlorine, and chlorine contaminated media (organic and inorganic), formic and acetic acids, acetic anhydride, and seawater and brine solutions.

- High-temperature resistance: It can withstand high temperatures and maintain its strength and toughness.

- Oxidation resistance: The chromium content provides resistance to oxidizing media, while the molybdenum and copper provide resistance to reducing environments.

- Fabricability: Despite its durability, Hastelloy C-2000 can be fabricated using the same methods as other high-nickel alloys.

Applications of Hastelloy C-2000:

Hastelloy C-2000 is used in a variety of applications that require exceptional corrosion resistance, such as:

- Chemical processing equipment

- Reactor vessels and heat exchangers

- Pharmaceutical industries

- Petrochemical industries

- Flue gas desulfurization systems

Metallographic Structure:

Hastelloy C-2000 has a face-centered cubic (FCC) crystal structure, which contributes to its ductility and high-temperature strength.

When considering Hastelloy C-2000 for specific applications, it is essential to consult with material specialists and review the relevant standards and specifications to ensure proper use and performance.

Hastelloy C-2000 UNS N06200 Nickel Alloy steel pipe

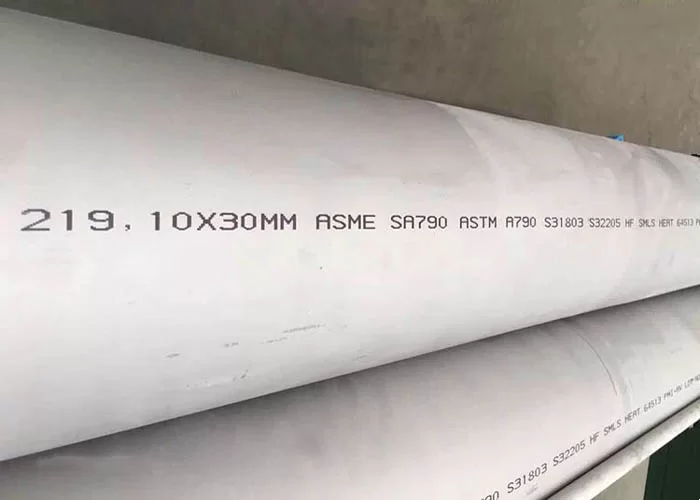

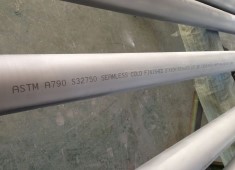

A790 S32750 Super Duplex Pipe |

A789 S31803 Tube |

A790 UNS S31803 Pipe |

Seamless Duplex SS Tube |

Super Duplex S32205 Pipe |

Super Dupex S32760 Pipe |

Availability:

Hastelloy C-2000 is available in various forms, including pipe, tube, sheet, plate, bar, fitting, and flanges. The pipes made from this alloy are used in environments where high resistance to corrosion is required, and they can be manufactured to meet specific size and shape requirements as needed for industrial applications.

When dealing with Hastelloy C-2000 or any other high-performance alloy, it’s crucial to work with materials that meet the specifications and standards appropriate for your industry, such as ASTM, ASME, and others. Always consult with a materials engineer or a professional in the field to ensure the correct alloy and product form is selected for your specific needs.

The UNS N06200, known as Hastelloy C-2000, is a versatile nickel alloy with numerous properties and applications. Below is a detailed breakdown of various aspects of this material:

Process Performance:

Hastelloy C-2000 can be processed using standard fabrication techniques used for nickel-based superalloys. This includes welding, machining, hot and cold working, and forming.

Solid Solution Strengthening:

The high nickel content in Hastelloy C-2000 provides solid solution strengthening, which contributes to its overall strength and resistance to corrosion at high temperatures.

Yield Strength:

The yield strength of Hastelloy C-2000 will vary depending on the form and the specific heat treatment used. Generally, it has a high yield strength compared to other materials, which helps it maintain its shape under stress.

Heat Treatment Process:

Heat treatment for Hastelloy C-2000 typically involves solution annealing. This process involves heating the alloy to a high temperature to dissolve the alloying elements into a solid solution and then rapidly cooling it to retain those elements in solution.

Creep Performance:

Hastelloy C-2000 exhibits excellent creep resistance due to its balanced alloy composition, making it suitable for high-temperature applications where components may be subject to long-term stress.

Chemical Composition:

As mentioned earlier, Hastelloy C-2000’s composition includes Nickel, Chromium, Molybdenum, Copper, Iron, Manganese, Silicon, Carbon, Vanadium, Phosphorus, and Sulfur.

Mechanical Properties:

The mechanical properties of Hastelloy C-2000 include high tensile strength, good ductility, and excellent fatigue resistance. These properties are maintained even in harsh environments.

Density/Specific Gravity:

The density of Hastelloy C-2000 is approximately 8.50 g/cm³.

Elastic Modulus:

The elastic modulus of Hastelloy C-2000 is typically around 206 GPa, although this can vary slightly depending on the exact processing and heat treatment.

Corresponding Material:

There may not be a direct equivalent to Hastelloy C-2000, but other materials in the Hastelloy family, like C-276 or C-22, have similar corrosion-resistant properties, albeit with different compositions.

Application Field:

Hastelloy C-2000 is used in chemical processing, petrochemicals, pharmaceutical industries, and any other field where its corrosion resistance and high-temperature performance are needed.

Fatigue Performance:

The alloy has good resistance to fatigue, especially in corrosive environments, which is critical for components that experience cyclic loading.

Characteristics:

Hastelloy C-2000 is characterized by its excellent corrosion resistance, especially in reducing environments, its ability to withstand high temperatures, and its durability in harsh conditions.

Tensile Strength:

The tensile strength is high, often above 690 MPa, depending on the heat treatment and condition of the material.

Corrosion Resistance Performance:

Hastelloy C-2000 is extremely resistant to a wide range of chemical environments, including hot contaminated mineral acids, chlorine, and brine solutions.

Process Requirements:

Working with Hastelloy C-2000 requires specific processing requirements to maintain its properties, including appropriate heat treatment, welding techniques, and machining parameters.

Implementation Standard:

Materials like Hastelloy C-2000 are produced and tested according to various standards, such as ASTM, ASME, and others, to ensure they meet the necessary quality and performance requirements.

Hardness Index:

The hardness of Hastelloy C-2000 can vary, but it is typically in the range of Rockwell B 90-100.

Test:

Tension Test, Flattening Test, Hardness Test, or Bend Test; Hydrostatic Test or nondestructive electric test.

|

|

|