Most Common Mechanical Failure in Shell & Heat Exchanger Pipe

September 30, 2024

Chemical Steel Pipelines – Designing Application Pressure and Temperature

October 3, 2024

Service Life Prediction of Polyethylene Coated Steel Pipe for Elevated Temperature

Introduction

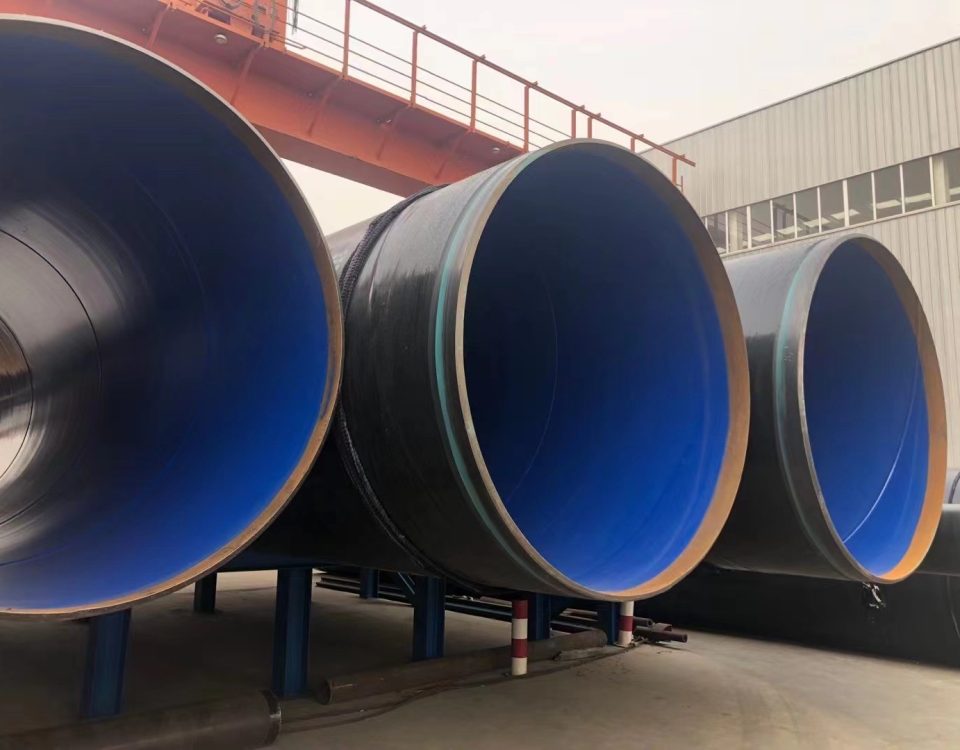

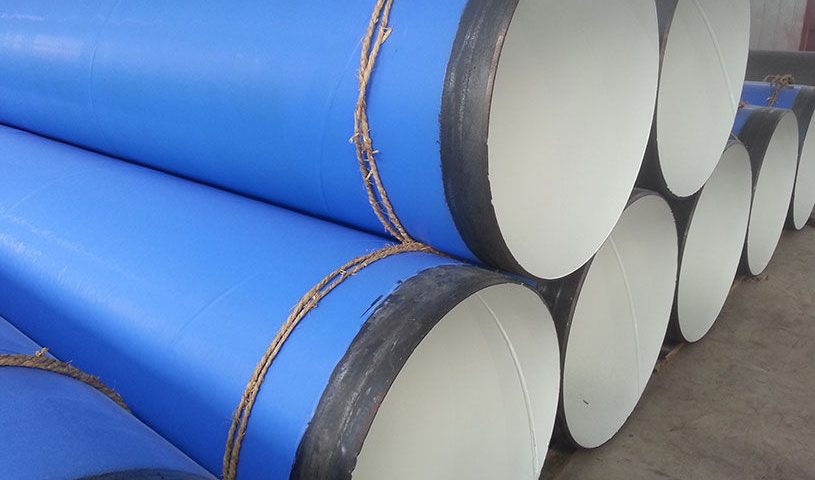

Polyethylene (PE) coated steel pipes are widely used in various industries for their excellent corrosion resistance and mechanical strength. However, when exposed to elevated temperatures, the service life of these pipes can be significantly affected. This guide outlines the key factors influencing the service life of polyethylene coated steel pipes at elevated temperatures and methods for predicting their longevity.

1. Understanding Polyethylene Coating

1.1 Properties of Polyethylene

-

- Chemical Resistance: PE provides excellent resistance to various chemicals and moisture.

- Mechanical Properties: Good tensile strength and flexibility, which enhance the overall durability of the pipe.

- Thermal Properties: PE has a relatively low melting point (around 120-130°C), which is critical when considering elevated temperature applications.

1.2 Functions of Coating

- Corrosion Protection: Prevents direct contact between steel and corrosive environments.

- Thermal Insulation: Provides some thermal insulation, though its effectiveness decreases at higher temperatures.

2. Factors Influencing Service Life

2.1 Temperature

- Elevated Temperatures: Prolonged exposure to temperatures above the recommended limits can lead to degradation of the PE coating.

- Thermal Cycling: Repeated heating and cooling cycles can cause thermal stress, leading to cracking or peeling of the coating.

2.2 Environmental Conditions

- Humidity: High humidity can accelerate the degradation of the PE coating.

- Chemical Exposure: Exposure to aggressive chemicals can compromise the integrity of the coating.

2.3 Mechanical Stress

- Bending and Compression: Mechanical stresses can cause micro-cracks in the coating, leading to moisture ingress and corrosion of the underlying steel.

- Installation Factors: Poor installation practices can result in localized stress points.

3. Degradation Mechanisms

3.1 Thermal Degradation

- Oxidative Degradation: At elevated temperatures, the oxidation rate of PE increases, leading to embrittlement.

- Softening and Flow: PE can soften at high temperatures, potentially leading to flow and loss of protective properties.

3.2 Mechanical Failure

- Cracking: Stress concentrations can lead to cracking of the coating.

- Delamination: The bond between the PE coating and the steel( process of Coated Steel Pipe) substrate can weaken, causing separation.

4. Service Life Prediction Methods

4.1 Empirical Models

- Arrhenius Model: Relates temperature to the rate of reaction, allowing for prediction of degradation rates.

k=Ae−EaRT

Where:

- k = rate constant

- A = pre-exponential factor

- Ea = activation energy

- R = universal gas constant

- T = absolute temperature (Kelvin)

4.2 Accelerated Aging Tests

- Thermal Aging: Subjecting samples to elevated temperatures for a specified period to simulate long-term aging.

- Mechanical Testing: Evaluating the mechanical properties of the coating after exposure to high temperatures to assess integrity.

4.3 Life Cycle Assessment (LCA)

- Comprehensive Evaluation: Assessing environmental, economic, and social impacts throughout the lifespan of the coated pipes.What is the difference between FBE coating pipe and epoxy coating pipe ?.

- Durability Modeling: Integrating various factors influencing performance to predict service life under real-world conditions.

5. Maintenance and Mitigation Strategies

5.1 Regular Inspections

- Conduct visual inspections and non-destructive testing (NDT) to identify early signs of coating failure.

5.2 Protective Measures

- Insulation: Use thermal insulation materials to minimize heat exposure.

- Barrier Coatings: Apply additional protective coatings for enhanced resistance to high temperatures and chemicals.

5.3 Material Selection

- Consider using high-temperature resistant polyethylene or alternative materials that can withstand elevated temperatures without significant degradation.

6. Conclusion

Predicting the service life of polyethylene coated steel pipes at elevated temperatures requires a comprehensive understanding of the material properties, environmental factors, and degradation mechanisms. By employing empirical models, accelerated aging tests, and regular maintenance, industries can effectively manage the longevity and performance of these critical components.

7. References

- ASTM Standards for Polyethylene Coatings

- Research Papers on High-Temperature Performance of Polyethylene

- Manufacturer Guidelines for Polyethylene DIN 30670 3PE Coated Carbon Steel Pipe 12 Inch SCH40 External PE coated steel pipe

This overview provides insights into the service life prediction of polyethylene coated steel pipes under elevated temperatures. If you need further details or specific sections expanded, let me know!

-steel-pipe.jpg)