reinforce the best pipe fitting price list

August 19, 2025

Alloy 20 UNS N08020 W.Nr. 2.4660: Bar, Sheet, Plate, Tubing, Pipe, Fittings, Flanges

August 27, 2025Alloy 625 Grade 1 / UNS N06625 / W.NR. 2.4856: A Comprehensive Overview

Introduction to Alloy 625

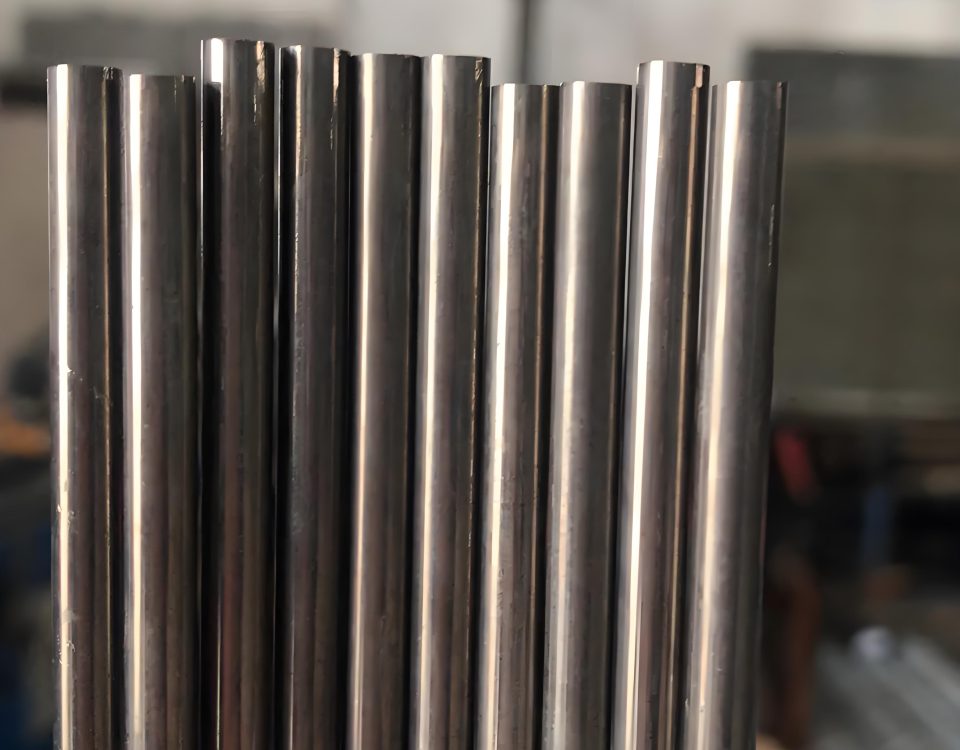

Alloy 625, also known as Inconel 625, UNS N06625, or W.Nr. 2.4856, is a nickel-chromium-molybdenum alloy renowned for its exceptional corrosion resistance, high strength, and fabricability. Developed in the 1960s, it is widely used in industries requiring materials that can withstand extreme environments, such as marine engineering, chemical processing, and aerospace. The alloy’s unique combination of elements provides outstanding resistance to pitting, crevice corrosion, and oxidation, making it ideal for applications in harsh conditions. Grade 1 refers to the annealed condition, which offers the best balance of properties for general use.

The alloy’s versatility extends to various forms, including pipes, sheets, bars, and wires, allowing it to be tailored to specific needs. Its high nickel content ensures ductility and toughness, while molybdenum and niobium enhance its strength and corrosion resistance. Alloy 625 maintains its properties over a wide temperature range, from cryogenic to 1800°F (982°C), making it suitable for both low and high-temperature applications. In comparison to other materials like Incoloy 901 or carbon steel pipes such as ASTM A671 CC60, Alloy 625 offers superior performance in corrosive environments but at a higher cost. This article provides a detailed exploration of Alloy 625’s chemical composition, mechanical properties, corrosion resistance, manufacturing processes, applications, and more, with tables for quick reference. By understanding its characteristics, engineers can better appreciate its role in modern industrial solutions.

Chemical Composition and Material Analysis

The chemical composition of Alloy 625 is carefully balanced to achieve its remarkable properties. The alloy consists of nickel (minimum 58%), chromium (20-23%), molybdenum (8-10%), niobium plus tantalum (3.15-4.15%), iron (maximum 5%), and small amounts of carbon (maximum 0.10%), manganese (maximum 0.50%), silicon (maximum 0.50%), phosphorus (maximum 0.015%), sulfur (maximum 0.015%), aluminum (maximum 0.40%), titanium (maximum 0.40%), and cobalt (maximum 1.0%). This composition is specified in standards like ASTM B443 and AMS 5599, ensuring consistency across manufacturers.

Nickel forms the base, providing resistance to reducing environments and high-temperature stability. Chromium contributes to oxidation resistance by forming a protective oxide layer, while molybdenum enhances resistance to pitting and crevice corrosion in chloride-containing media. Niobium stabilizes the alloy against sensitization and intergranular corrosion, also aiding in strengthening through precipitation hardening. The low carbon content minimizes carbide precipitation during welding, preserving corrosion resistance in the heat-affected zone. Compared to Incoloy 901 (40-45% nickel, 11-14% chromium, 5-7% molybdenum), Alloy 625 has higher nickel and molybdenum, offering better corrosion resistance but slightly lower high-temperature strength. In contrast to carbon steels like API 5L PSL2 BNS (maximum 0.26% carbon, 1.20% manganese), Alloy 625’s high alloy content makes it far more resistant to corrosion but more expensive and harder to fabricate. The material’s austenitic structure ensures excellent ductility and toughness, making it suitable for cryogenic applications as well. Analysis shows that Alloy 625’s composition allows it to perform in a wide range of corrosive environments, from seawater to acidic solutions, outperforming many stainless steels and making it a preferred choice for demanding industries.

Mechanical Properties of Alloy 625

Alloy 625 exhibits excellent mechanical properties that remain consistent across a broad temperature range. At room temperature, the annealed material (Grade 1) has a minimum tensile strength of 827 MPa (120 ksi), yield strength of 414 MPa (60 ksi), and elongation of 30%. Hardness is typically 145-220 Brinell. These properties are maintained up to elevated temperatures; for example, at 649°C (1200°F), tensile strength is about 724 MPa (105 ksi), yield strength 276 MPa (40 ksi), and elongation 45%. The alloy’s high ductility and toughness allow it to withstand dynamic loads without brittle failure. [

The strength is derived from solid-solution hardening by molybdenum and niobium, with no significant precipitation hardening. Heat treatment involves annealing at 871-1038°C (1600-1900°F) to relieve stresses, or solution treatment at 1093-1204°C (2000-2200°F) for optimal creep resistance. Compared to Inconel 718 (tensile strength 1275 MPa at room temperature), Alloy 625 has lower strength but better fabricability and corrosion resistance. Incoloy 901 offers similar strength (1150 MPa tensile) but is more prone to corrosion in certain environments. Carbon steel pipes like ASTM A671 CC60 have much lower strength (415-550 MPa tensile) and require coatings for protection. API 5L PSL2 BNS has yield of 245 MPa, suitable for pipelines but not for high-temperature service. Alloy 625’s mechanical properties make it ideal for applications requiring both strength and corrosion resistance, such as marine and chemical processing equipment. Its ability to retain properties after long-term exposure to elevated temperatures, with minimal degradation, ensures long service life in demanding conditions.

Corrosion Resistance Characteristics

Alloy 625 is celebrated for its outstanding corrosion resistance in a variety of aggressive environments. It resists pitting and crevice corrosion in chloride media, with a pitting resistance equivalent number (PREN) of about 52, far superior to stainless steels. The alloy is virtually immune to chloride stress-corrosion cracking and performs well in oxidizing acids like nitric and sulfuric, as well as reducing acids. In seawater, it shows no pitting or crevice attack even after prolonged exposure, and it resists erosion-corrosion in high-velocity fluids. Corrosion rates in boiling phosphoric acid are low (0.1-0.2 mm/year), and in hydrochloric acid, it maintains integrity up to certain concentrations.

The high molybdenum and chromium content forms a passive film that protects against localized corrosion, while niobium stabilizes against intergranular attack. Compared to Incoloy 901, which has good oxidation resistance but is susceptible to sulfidation, Alloy 625 is more versatile in mixed environments. Inconel 718 offers similar resistance but is strengthened differently, making 625 better for welded structures. Carbon steels like ASTM A671 CC60 require coatings for corrosion protection, as they corrode rapidly in chlorides or acids. API 5L PSL2 BNS is designed for sour service but needs additional protection for general corrosion. Alloy 625’s resistance extends to high-temperature gases, with low oxidation rates up to 982°C (1800°F). This makes it suitable for flue gas desulfurization systems and offshore platforms, where long-term exposure to corrosives is common. Its performance in alkaline environments and organic acids further broadens its application scope, ensuring reliability in diverse industrial settings.

Manufacturing and Processing of Alloy 625

Alloy 625 is manufactured using standard processes for nickel alloys, including vacuum induction melting followed by electroslag remelting for cleanliness. Hot working is done between 871-1204°C (1600-2200°F), with annealing at 871-1038°C to restore ductility. Cold working enhances strength but reduces ductility, so it’s followed by annealing. Welding is excellent, using matching filler metals like ERNiCrMo-3, with no pre-heat required but clean surfaces essential to avoid contamination. Post-weld heat treatment is not necessary for corrosion resistance but may be used to relieve stresses.

Machining requires rigid setups and carbide tools due to work-hardening, with cutting speeds of 10-30 m/min. Forming is done in the annealed condition, with bending radii 1.5-3 times thickness. Compared to Incoloy 901, which requires precipitation hardening, Alloy 625 is easier to process but still demands care to avoid cracking. Inconel 718 is similar but more sensitive to heat treatment. Carbon steels like ASTM A671 CC60 are simpler to weld and form but lack high-temperature capabilities. API 5L PSL2 BNS involves LSAW welding, focused on pipeline integrity. Alloy 625’s fabricability allows for complex shapes in pipes, tubes, and fittings, making it versatile for custom applications in chemical and marine industries. Proper processing ensures the alloy retains its corrosion resistance and mechanical properties, critical for long-term performance.

Applications of Alloy 625

Alloy 625 finds extensive use in industries requiring superior corrosion resistance and strength. In marine engineering, it is used for seawater equipment, propeller blades, and submarine fittings due to its resistance to pitting and erosion. Chemical processing applications include reactors, heat exchangers, and piping for handling acids and chlorides. Aerospace uses it for exhaust systems, turbine shrouds, and fuel lines, benefiting from high-temperature strength. Nuclear reactors employ it for core components, resisting radiation and corrosion. Pollution control equipment, like scrubbers for flue gas desulfurization, utilizes its resistance to sulfur compounds.

Oil and gas industry applications include downhole tubing and valves in sour wells, where SSC resistance is key. Compared to Incoloy 901, used in gas turbines, Alloy 625 is more corrosion-focused. Inconel 718 is for high-strength aerospace parts, while ASTM A671 CC60 is for low-temperature piping, and API 5L PSL2 BNS for sour gas lines. Alloy 625’s versatility extends to medical devices and food processing, where non-toxicity and cleanliness are important. Its ability to be welded without loss of properties allows for large structures in offshore platforms and chemical plants. The alloy’s long service life in harsh environments reduces maintenance costs, making it a preferred choice for critical infrastructure worldwide.

Technical Specifications and Parameter Table

The following table summarizes key parameters for Alloy 625 Grade 1, including chemical composition, mechanical properties, and other specifications.

| Parameter | Specification |

|---|---|

| Alloy Designation | Alloy 625 Grade 1 (UNS N06625, W.Nr. 2.4856) |

| Chemical Composition | Ni: 58.0 min, Cr: 20.0-23.0, Mo: 8.0-10.0, Nb+Ta: 3.15-4.15, Fe: 5.0 max, C: 0.10 max, Mn: 0.50 max, Si: 0.50 max, P: 0.015 max, S: 0.015 max, Al: 0.40 max, Ti: 0.40 max, Co: 1.0 max |

| Density | 8.44 g/cm³ (0.305 lb/in³) |

| Melting Range | 1290-1350°C (2350-2460°F) |

| Tensile Strength (Room Temp, Annealed) | 827 MPa (120 ksi) min |

| Yield Strength (Room Temp, Annealed) | 414 MPa (60 ksi) min |

| Elongation (Room Temp) | 30% min |

| Hardness | 145-220 Brinell |

| Corrosion Resistance | Excellent in pitting, crevice, oxidation; PREN ~52 |

| Oxidation Resistance | Up to 982°C (1800°F) |

| Heat Treatment (Annealing) | 871-1038°C (1600-1900°F), air cool |

| Weldability | Excellent, no PWHT needed |

| Standards | ASTM B443, AMS 5599, UNS N06625 |

| Applications | Marine, chemical processing, aerospace, nuclear, oil/gas |

This table serves as a quick reference for Alloy 625’s capabilities, aiding in material selection for various engineering needs.

Comparison with Other Alloys

Alloy 625 is often compared to other materials for its corrosion resistance and strength. Inconel 718, strengthened by precipitation hardening, has higher room-temperature strength (1275 MPa tensile) but lower corrosion resistance in reducing environments. Incoloy 901, with similar nickel base, offers good high-temperature strength but is more susceptible to oxidation than 625. ASTM A671 CC60, a carbon steel for low temperatures, has tensile strength 415-550 MPa but poor corrosion resistance without coatings. API 5L PSL2 BNS, for sour service pipelines, has yield 245 MPa and requires NACE compliance, but lacks 625’s high-temperature capabilities. Alloy 625 excels in versatility, outperforming stainless steels in chlorides and carbon steels in acids, making it preferred for severe conditions despite higher cost.

Challenges and Limitations

Despite its advantages, Alloy 625 has challenges in fabrication and cost. Its work-hardening rate requires careful machining with low speeds and heavy feeds to avoid tool wear. Welding is excellent, but contamination must be avoided to prevent embrittlement. At temperatures above 1000°C (1832°F), it can lose ductility due to phase precipitation, limiting long-term use in ultra-high heat. Cost is a major limitation, being significantly higher than carbon steels like ASTM A671 CC60 or API 5L BNS, restricting it to applications where corrosion resistance is critical. Compared to Inconel 718, 625 is less strong at room temperature but better in corrosives. Incoloy 901 is cheaper but less resistant to pitting. These limitations are mitigated by proper design and processing, but they require careful consideration in material selection to balance performance and economics.

Future Trends and Innovations

The future of Alloy 625 lies in advanced manufacturing and applications in emerging industries. Additive manufacturing is being explored to create complex geometries for aerospace and medical devices, reducing waste and enabling customization. Innovations in heat treatments are improving high-temperature stability, extending its use in advanced gas turbines and nuclear fusion. The alloy’s role in renewable energy, such as offshore wind turbines and geothermal systems, is growing due to its marine corrosion resistance. Sustainability efforts focus on recycling nickel alloys to reduce costs and environmental impact. Compared to Inconel 718’s use in 3D printing for engines, 625 emphasizes corrosion-focused innovations. ASTM A671 and API 5L materials are seeing coating advancements, but 625’s inherent properties position it for high-value applications. As industries demand materials for extreme conditions, Alloy 625 will evolve with nanotechnology coatings and alloy modifications, maintaining its status as a premier superalloy.

Alloy 625 Grade 1 (UNS N06625, W.Nr. 2.4856) stands as a versatile superalloy with exceptional corrosion resistance and mechanical properties for demanding environments. Its nickel-chromium-molybdenum composition ensures performance in marine, chemical, and aerospace applications, with strength maintained across wide temperatures. Compared to Inconel 718 and Incoloy 901, it offers superior corrosion resistance, while outperforming carbon steels like ASTM A671 CC60 and API 5L BNS in harsh conditions. The provided table summarizes its key parameters, aiding in selection. Challenges like cost and fabrication are offset by its durability, and future innovations in manufacturing will expand its use. Alloy 625 remains a critical material for industries requiring reliability in corrosive settings, ensuring long-term performance and safety.