ASTM B167 UNS N06600 Nickel Alloy Steel Seamless Pipe

May 29, 2024

EN 10083-2 Grade C45 Carbon Steel Seamless Pipes

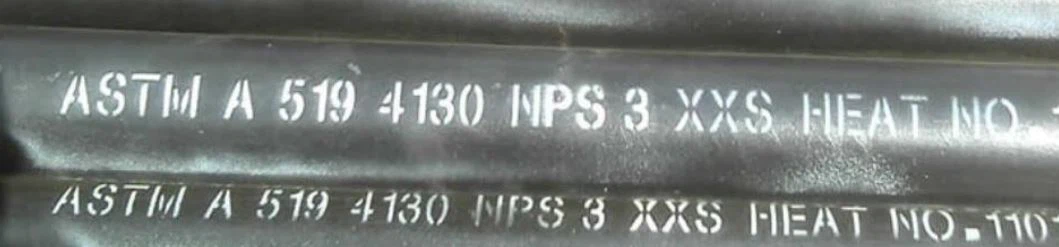

June 6, 2024ASTM A519 is a specification for seamless carbon and alloy steel mechanical tubing. ASTM A519 Grade 4130 is a low-alloy steel containing chromium and molybdenum as strengthening agents. Here are some details about the ASTM A519 4130 Alloy Steel Pipe:

Chemical Composition

The chemical composition of ASTM A519 Grade 4130 steel is typically:

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.28 – 0.33 |

| Manganese (Mn) | 0.40 – 0.60 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.040 |

| Silicon (Si) | 0.15 – 0.35 |

| Chromium (Cr) | 0.80 – 1.10 |

| Molybdenum (Mo) | 0.15 – 0.25 |

Mechanical Properties

The mechanical properties of ASTM A519 Grade 4130 typically include:

- Tensile Strength (MPa): 560 – 700

- Yield Strength (MPa): 460 (minimum)

- Elongation (% in 50mm): 20 (minimum)

- Hardness (Brinell): 197 (maximum)

Applications

ASTM A519 Grade 4130 alloy steel pipe is commonly used in applications requiring a high strength-to-weight ratio, such as:

- Aircraft engine mounts and welded tubing applications.

- Structural parts such as landing gear and roll cages.

- Oil and gas drilling, including wellhead and completion equipment.

- Motorsports and automotive components.

- Industrial machinery.

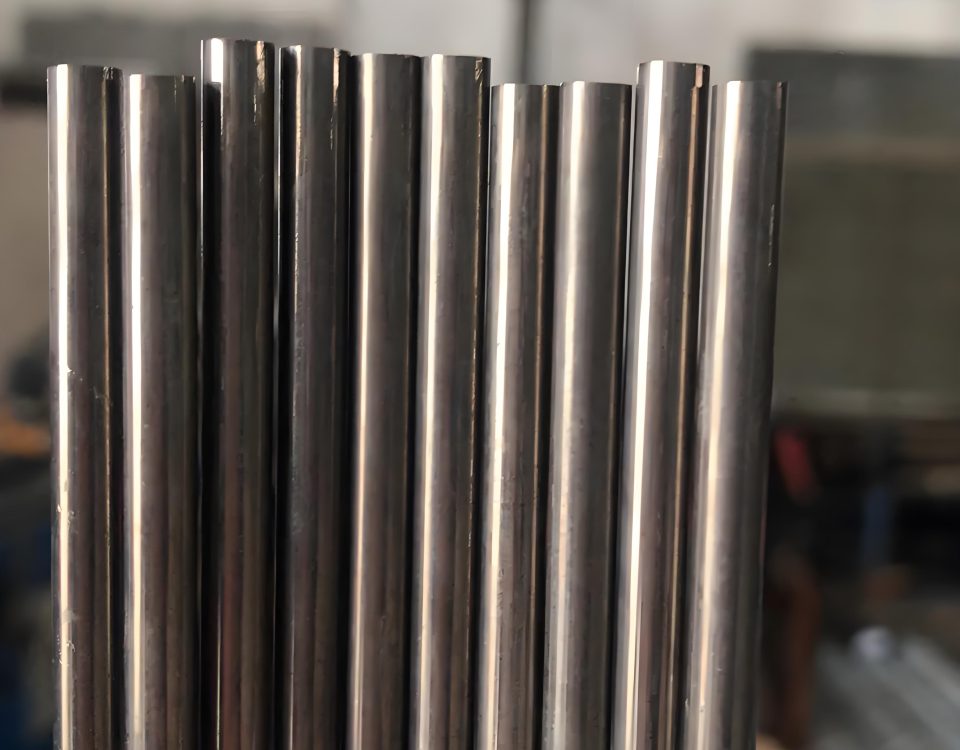

Manufacturing Process

The tubing is manufactured by a seamless process and can be hot finished or cold finished. Standard manufacturing processes include:

- Hot Finished: Involves heating the material and rolling it to the desired dimensions.

- Cold Finished: Involves drawing or cold rolling the material to achieve closer tolerances and improved surface finishes.

Heat Treatment

ASTM A519 Grade 4130 alloy steel can be heat treated to improve its mechanical properties. Common heat treatments include:

- Normalizing: Heating to a temperature above the critical range, followed by air cooling.

- Quenching and Tempering: Heating to a high temperature, quenching in oil or water, followed by reheating to a lower temperature and air cooling.

Availability and Sizing

ASTM A519 4130 alloy steel pipes are available in various sizes and wall thicknesses. Common sizes range from small-diameter tubing to larger structural sizes, depending on the application requirements.

Standards and Specifications

Ensure that the material meets the ASTM A519 specification for mechanical tubing. This includes adherence to the specified chemical composition, mechanical properties, manufacturing processes, and testing methods.

Conclusion

ASTM A519 4130 alloy steel pipe is a versatile and high-strength material suitable for various demanding applications. Its balance of strength, toughness, and fatigue resistance makes it a popular choice in the aerospace, automotive, oil and gas, and industrial sectors. Always ensure that the material is sourced from reputable suppliers and meets the required specifications for your particular application.