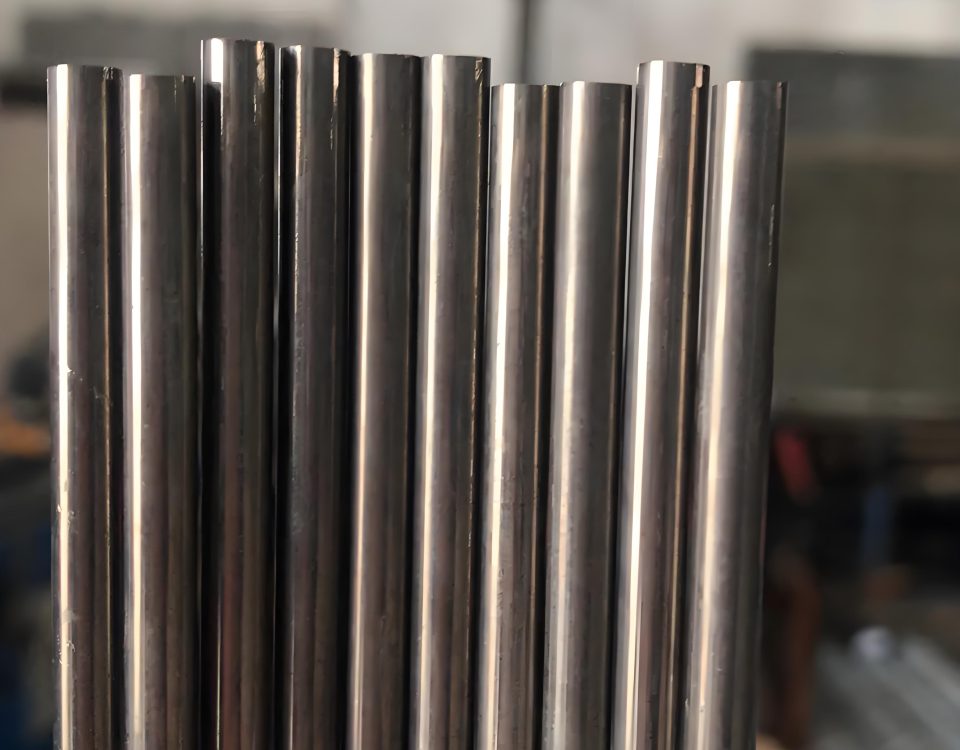

Hastelloy C22 N06022 2.4602 NiCr21Mo14W Nickel-Based Alloy Pipe

August 27, 2024

Global Pipeline Construction Outlook 2024: New LNG Terminals Call for More Pipelines

September 3, 2024ASTM B619 UNS N06022 Hastelloy C22 Pipe

Corresponding to the other nickel alloy grades, one of the main benefits of using Alloy C22, or what is also known as Hastelloy C22 is that the metal has one of the best corrosion resistance properties. This austenitic grade of Alloy C22 Seamless Pipe is able to resist corrosion, especially in oxidizing environments as it is able to resist corrosion in aqueous media as well. This particular resistance property of the Hastelloy C22 pipe proves to be rather beneficial to those factories that have upset conditions. More often than not, in chemical processing systems, the pipes need to encounter both reducing and oxidizing conditions (upset) at varying temperature levels.

ASTM B619 UNS N06022 Hastelloy C22 Pipe

Introduction

In industries that demand exceptional material performance under extreme conditions, Hastelloy C22 pipes are a top choice. These pipes, specified under ASTM B619 and recognized by their UNS number N06022, are renowned for their outstanding resistance to corrosion and high-temperature stability. This article explores the characteristics, applications, and benefits of Hastelloy C22 pipes, emphasizing their critical role in enhancing the reliability and efficiency of industrial systems.

Understanding Hastelloy C22

What is Hastelloy C22?

Hastelloy C22 is a versatile nickel-chromium-molybdenum-tungsten alloy known for its excellent resistance to pitting, crevice corrosion, and stress corrosion cracking. Its unique composition allows it to perform exceptionally well in both oxidizing and reducing environments.

Key Properties of Hastelloy C22

- Corrosion Resistance: Provides superior protection against a wide range of corrosive chemicals, including chlorides, acids, and seawater.

- High-Temperature Stability: Retains its mechanical properties and corrosion resistance at elevated temperatures, making it suitable for high-temperature applications.

- Versatility: Adaptable to various applications due to its resistance to multiple forms of corrosion.

Characteristics of ASTM B619 UNS N06022 Hastelloy C22 Pipes

Hastelloy C22 pipe Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy C22 | 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000 , MPa – 690 | Psi – 45000 , MPa – 310 | 45 % |

ASTM B622 UNS N06022 Pipe Chemical Composition

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| C22 | 0.010 max | 0.50 max | 0.08 max | 0.02 max | 2.50 max | 50.015 min* | 20.00 – 22.50 | 2.00 – 6.00 | 12.50 – 14.50 | 0.02 max |

Nickel C22 Pipe Equivalent

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN | OR |

| Hastelloy C22 | 2.4602 | N06022 | NW 6022 | – | NiCr21Mo14W | – |

Check Nickel Alloy C22 Cold Drawn Pipe Price Per Kg. Manufacturer of 108Mm Diameter Hastelloy C22 Welded Pipe , Most recognized and widely used Hastelloy Alloy C22 Pipe Stockist, Seamless 1.5 inch Hastelloy UNS N06022 Seamless Pipe Dealer, Exporter of Nickel C22 Pipe, C22 Alloy EFW Pipe.

Pressure Rating of Hastelloy DIN 2.4602 Pipe

| Pipe O.D. (in.) |

Wall Thickness of Pipe (inches) | |||||||

|---|---|---|---|---|---|---|---|---|

| .028 | .035 | .049 | .065 | .083 | .095 | .109 | .120 | |

| Working Pressure (psig) | ||||||||

| 1/8 | 7900 | 10100 | ||||||

| 1/4 | 3700 | 4800 | 7000 | 9500 | ||||

| 5/16 | 3700 | 5400 | 7300 | |||||

| 3/8 | 3100 | 4400 | 6100 | |||||

| 1/2 | 2300 | 3200 | 4400 | |||||

| 3/4 | 2200 | 3000 | 4000 | 4600 | ||||

| 1 | 2200 | 2900 | 3400 | 3900 | 4300 | |||

Trade Names of Hastelloy Alloy C22 Pipe

| UNS: | N06022 |

| Specifications: | ASTM B622, ASTM B619, ASTM B775, ASTM B516, ASTM B626, ASTM B751 |

| international Specifications: | ISO 6207, din 17751 |

Seamless Construction

Hastelloy C22 pipes are available in seamless construction, offering a smooth and uniform surface that minimizes the risk of leaks and ensures efficient fluid flow.

Durability

These pipes are crafted from high-quality Hastelloy C22, providing exceptional durability and longevity. They resist corrosion, oxidation, and wear, ensuring reliable operation in the most demanding environments.

Versatility

Hastelloy C22 pipes are available in various sizes and wall thicknesses, allowing for versatile configurations in industrial systems. They can be customized to meet specific requirements, ensuring optimal performance.

Applications of Hastelloy C22 Pipes

Chemical Processing

In chemical processing plants, Hastelloy C22 pipes are favored for their resistance to corrosive chemicals and high temperatures. They ensure the safe and efficient transport of hazardous substances.

Pharmaceutical Industry

Hastelloy C22 pipes are utilized in the pharmaceutical industry to maintain the purity and integrity of products. Their smooth surfaces and resistance to corrosion make them suitable for sterile environments.

Oil and Gas Industry

In the oil and gas sector, Hastelloy C22 pipes are employed in refineries and processing facilities to handle high-pressure and high-temperature applications. Their strength and corrosion resistance make them a reliable choice.

Marine and Offshore

Hastelloy C22 pipes are ideal for marine and offshore applications, where exposure to saltwater and harsh conditions is common. Their superior corrosion resistance ensures long-term reliability and safety.

Benefits of Using Hastelloy C22 Pipes

Superior Corrosion Resistance

Hastelloy C22 pipes offer unparalleled corrosion resistance, ensuring long-lasting performance in aggressive environments. This reduces maintenance costs and extends the lifespan of industrial systems.

High Strength

The high strength of Hastelloy C22 pipes allows them to withstand high pressures and temperatures, making them suitable for demanding applications.

Cost-Effectiveness

While Hastelloy C22 pipes may have a higher initial cost, their durability and low maintenance requirements make them a cost-effective choice in the long run.

Conclusion

ASTM B619 UNS N06022 Hastelloy C22 pipes are indispensable components in modern industrial systems, offering seamless construction, durability, and versatility. Their excellent corrosion resistance and high strength make them suitable for a wide range of applications, from chemical processing to marine environments. As industries continue to demand reliable and efficient solutions, Hastelloy C22 pipes will remain a preferred choice for enhancing the performance and reliability of industrial systems.

FAQ

1. What are the main advantages of Hastelloy C22 pipes?

The main advantages include superior corrosion resistance, high strength, and excellent performance in both oxidizing and reducing environments.

2. In which industries are Hastelloy C22 pipes commonly used?

Industries such as chemical processing, pharmaceuticals, oil and gas, and marine commonly use these pipes due to their excellent properties.

3. How do Hastelloy C22 pipes enhance the performance of industrial systems?

Their corrosion resistance, high strength, and durability ensure reliable operation and reduce maintenance costs, enhancing overall system performance.

4. Are Hastelloy C22 pipes cost-effective?

Yes, their durability and low maintenance requirements make them a cost-effective choice in the long run, despite a higher initial cost.

5. What is the significance of ASTM B619 in relation to Hastelloy C22 pipes?

ASTM B619 is a standard specification for welded nickel and nickel-cobalt alloy pipes, ensuring the quality and performance of Hastelloy C22 pipes.