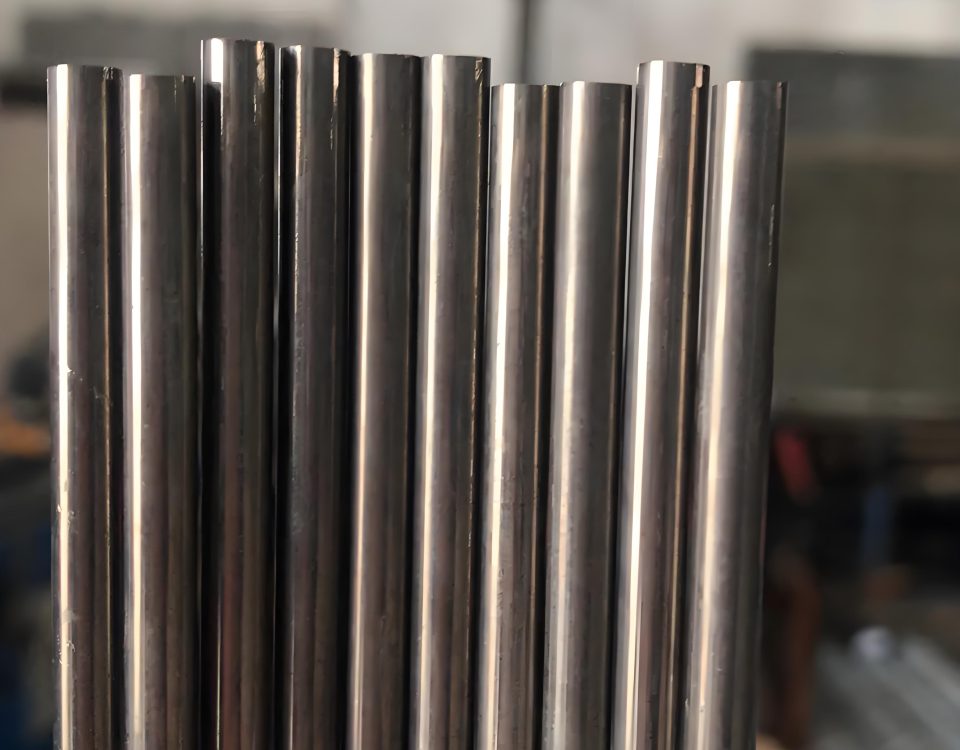

Monel 401 (UNS N04401 / W.Nr. 2.0842) Steel Pipe

July 24, 2024

Incoloy 825 (UNS N08825) Steel Pipe

August 3, 2024ASTM B644 C71520 Seamless Nickel Pipe

Introduction

ASTM B644 specifies the requirements for seamless nickel-copper alloy pipes, with UNS C71520 being a notable variant due to its excellent corrosion resistance and mechanical properties. This guide provides an in-depth look at the properties, applications, manufacturing processes, and typical industries that use C71520 pipes.

Detailed Chemical Composition

To ensure high performance in corrosive environments, the alloy’s chemical composition is finely balanced. Here’s a more detailed breakdown:

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 63.0 – 70.0 |

| Copper (Cu) | 29.0 – 33.0 |

| Iron (Fe) | 0.4 – 1.0 |

| Manganese (Mn) | 1.0 max |

| Zinc (Zn) | 0.5 max |

| Lead (Pb) | 0.05 max |

| Sulfur (S) | 0.02 max |

| Carbon (C) | 0.05 max |

| Silicon (Si) | 0.5 max |

Enhanced Mechanical Properties

C71520 pipes are known for their balance of strength and ductility. Here are additional mechanical properties:

| Property | Value |

|---|---|

| Tensile Strength | 50 ksi (345 MPa) min |

| Yield Strength | 15 ksi (105 MPa) min |

| Elongation | 30% min |

| Hardness | 80 HRB max |

| Modulus of Elasticity | 22,000 ksi (152 GPa) |

Extended Physical Properties

The physical properties of C71520 make it suitable for diverse applications:

| Property | Value |

|---|---|

| Density | 8.94 g/cm³ |

| Melting Point | 1149-1176°C (2100-2150°F) |

| Specific Heat | 0.091 Btu/lb·°F (380 J/kg·K) |

| Electrical Resistivity | 0.306 µΩ·m |

| Thermal Conductivity | 29 W/m·K |

| Coefficient of Expansion | 14.9 µm/m·°C (20-100°C) |

Manufacturing Processes

The production of ASTM B644 C71520 seamless nickel pipes involves several critical steps to ensure quality and performance:

- Melting and Casting: Raw materials are melted in an electric arc furnace or induction furnace. The molten metal is then cast into ingots or billets.

- Extrusion: The billets are heated and extruded into hollow tubes, forming the basic pipe shape.

- Cold Working: The extruded tubes undergo cold working processes such as drawing or pilgering to achieve the desired dimensions and mechanical properties.

- Annealing: Pipes are annealed to relieve internal stresses and improve ductility.

- Final Processing: Pipes are straightened, cut to length, and undergo surface finishing.

- Inspection and Testing: Rigorous inspections and tests, including nondestructive testing, are conducted to ensure compliance with specifications.

Detailed Applications

Marine Engineering

- Seawater Systems: Piping for seawater cooling systems, desalination plants, and ballast water systems.

- Marine Hardware: Shafts, fasteners, and other components exposed to seawater.

Chemical Processing

- Heat Exchangers: Tubing for heat exchangers handling corrosive chemicals.

- Process Piping: Piping systems in chemical plants where corrosion resistance is critical.

Oil and Gas Industry

- Offshore Drilling: Piping and tubing for offshore platforms and subsea installations.

- Production Equipment: Components in oil and gas extraction and processing.

Power Generation

- Nuclear Power Plants: Tubing for heat exchangers and condensers in nuclear reactors.

- Fossil Fuel Plants: Piping systems in boilers and heat exchangers.

Aerospace Industry

- Engine Components: Parts in jet engines and other high-temperature environments.

- Structural Components: Structural tubing and other components exposed to harsh conditions.

Advantages of C71520 Seamless Nickel Pipes

- Corrosion Resistance: Exceptional resistance to seawater and chemical corrosion.

- Mechanical Strength: High tensile and yield strength for demanding applications.

- Ductility: Good ductility, allowing for complex shapes and designs.

- Thermal Stability: Maintains properties at high temperatures.

- Longevity: Long service life in harsh environments, reducing maintenance costs.

Typical Industries

- Marine and Offshore: Shipping, offshore platforms, and naval applications.

- Chemical Processing: Chemical plants, refineries, and process industries.

- Oil and Gas: Exploration, drilling, and production facilities.

- Power Generation: Nuclear, thermal, and renewable energy plants.

- Aerospace: Aircraft, spacecraft, and defense applications.

Conclusion

ASTM B644 C71520 seamless nickel pipes are integral to industries where corrosion resistance, mechanical strength, and durability are critical. Their extensive use in marine, chemical, oil and gas, power generation, and aerospace industries underscores their versatility and reliability. Selecting the right material and ensuring compliance with relevant standards is crucial for the success of any project involving these high-performance pipes.