B704 UNS N06625 UNS N08825 Nickel Alloy Steel Pipe

May 25, 2024

ASTM A519 4130 Alloy Steel Pipe

June 2, 2024ASTM B167 UNS N06600 Nickel Alloy Steel Seamless Pipe

ASTM B167 UNS N06600 is an Inconel nickel-iron-chromium alloy with a minimum 72% nickel content, it exhibits good resistance to high-temperature corrosion and oxidation, excellent cold and hot processing and welding performance. ASTM B167 UNS N06600 seamless pipe & tube is manufactured in cold-worked annealed, hot-worked annealed, and hot-finished intended for general corrosion resistant and heat resistant applications. UNS N06600 is a high-temperature alloy, also known as Inconel 600, which is mainly composed of nickel, iron, chromium and other elements, and has excellent high-temperature strength, corrosion resistance and oxidation resistance, and is suitable for use in high-temperature and highly corrosive environments.

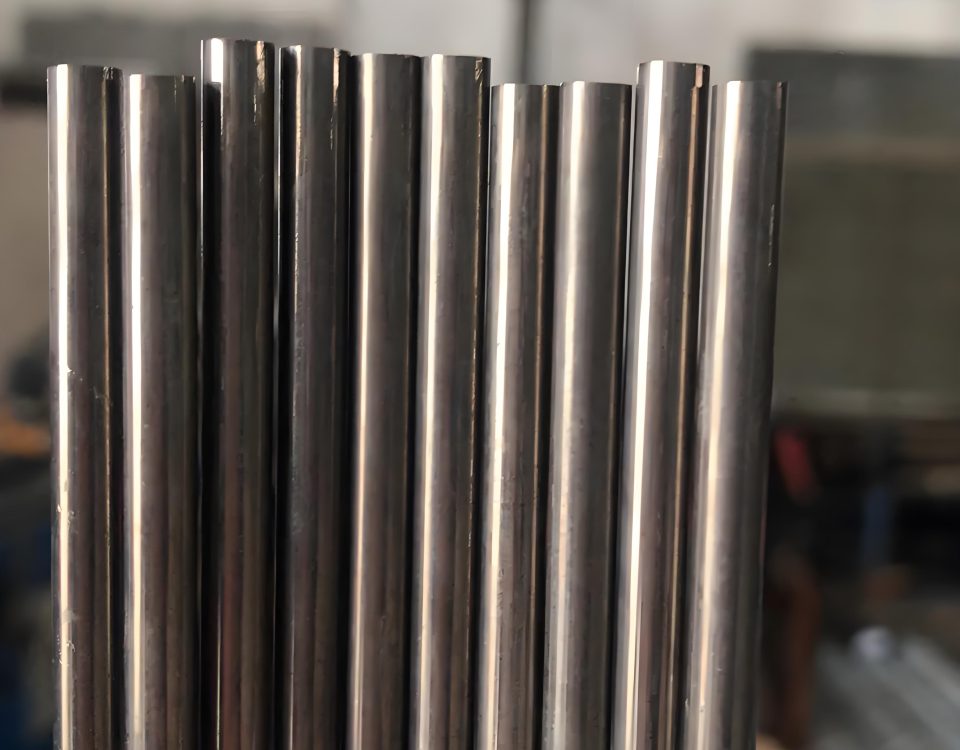

ASTM B167 UNS N06600 Nickel Alloy Seamless Pipe

We offer high-quality ASTM B167 UNS N06600 nickel alloy seamless pipes. These pipes, made from Inconel 600, are renowned for their excellent mechanical properties, high strength, and superior resistance to corrosion and high temperatures.

Product Features

- Material: Inconel 600 (UNS N06600)

- High Nickel Content: Minimum 72% nickel, providing excellent ductility and toughness

- Corrosion Resistance: Outstanding resistance to oxidation and corrosion at high temperatures

- Applications: Suitable for chemical processing, nuclear reactors, heat exchangers, aerospace, and marine engineering

Composition

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 72.0 min |

| Chromium (Cr) | 14.0 – 17.0 |

| Iron (Fe) | 6.0 – 10.0 |

| Manganese (Mn) | 1.0 max |

| Carbon (C) | 0.15 max |

| Silicon (Si) | 0.50 max |

| Copper (Cu) | 0.50 max |

| Sulfur (S) | 0.015 max |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength, min (psi) | 80,000 (550 MPa) |

| Yield Strength, min (psi) | 35,000 (240 MPa) |

| Elongation in 2 in. (50 mm), min (%) | 30% |

| Hardness (Brinell) | 150 – 220 HB |

Pipe Specifications

- Standard: ASTM B167

- Type: Seamless pipe

- Size Range:

- Outside Diameter: Up to 8 inches (203.2 mm)

- Wall Thickness: Varies based on size and application requirements

- Length: Custom lengths available upon request

Permissible Variations in Outside Diameter and Wall Thickness

Outside Diameter

| Outside Diameter (inches) | Permissible Variation (inches) |

|---|---|

| Up to and including 1/2″ | ± 0.004 |

| Over 1/2″ to 1-1/2″ | ± 0.006 |

| Over 1-1/2″ to 2-1/2″ | ± 0.010 |

| Over 2-1/2″ to 3-1/2″ | ± 0.016 |

| Over 3-1/2″ to 5″ | ± 0.020 |

Wall Thickness

| Wall Thickness (inches) | Permissible Variation |

|---|---|

| Up to 0.049 | ± 15% |

| 0.050 to 0.083 | ± 12.5% |

| Over 0.083 | ± 10% |

Materials Testing & Quality Assurance

- Chemical Composition Testing: Ensures compliance with specified chemical composition requirements.

- Tensile Property Testing: Verifies tensile strength, yield strength, and elongation.

- Hardness Testing: Confirms the material’s hardness range.

- Hydrostatic/Nondestructive Electric Testing: Ensures the integrity and quality of each pipe.

- Dimensional Inspection: Verifies compliance with specified dimensional tolerances.

- Visual Inspection: Detects surface defects and imperfections.

- Microstructure Analysis: Occasionally performed to confirm acceptable microstructure.

- Corrosion Resistance Testing: Ensures suitability for specific corrosive environments.

Applications

Due to its exceptional properties, ASTM B167 UNS N06600 nickel alloy seamless pipe is used in a wide range of industries and applications, including:

- Chemical Processing: For handling corrosive chemicals and high-temperature processes.

- Nuclear Industry: For reactor components and heat exchangers.

- Aerospace: For high-temperature and corrosion-resistant components.

- Marine Engineering: For seawater and marine environments.

- Heat Exchangers: For efficient heat transfer under corrosive conditions.

Conclusion

Our ASTM B167 UNS N06600 nickel alloy seamless pipes are designed to meet the highest standards of quality and performance. With their superior resistance to high temperatures and corrosion, these pipes are ideal for critical applications across various industries. Contact us to learn more about how our products can meet your specific needs.