OCTG ( Oil Country Tubular Goods ) Industry Forecast and Potential Opportunities Analysis by 2023

July 14, 2024

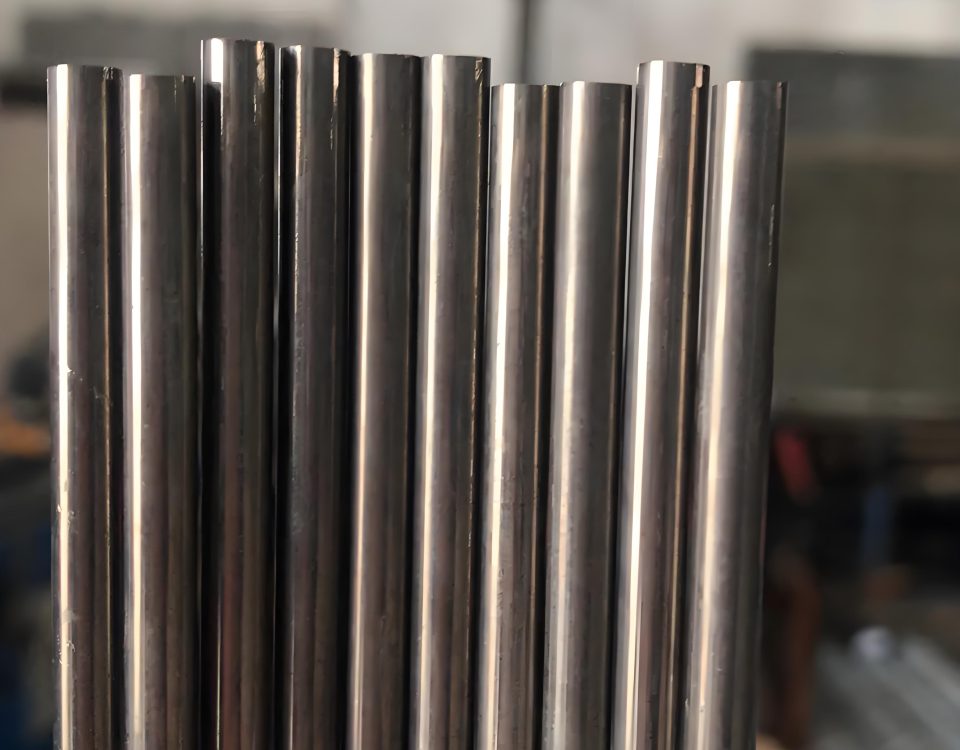

Monel 401 (UNS N04401 / W.Nr. 2.0842) Steel Pipe

July 24, 2024

Abstract

Grade 6 Ti-5Al-2.5Sn titanium alloy is known for its excellent mechanical properties and corrosion resistance, making it suitable for high-performance applications, especially in the aerospace industry. This paper provides an exhaustive analysis of Grade 6 Ti-5Al-2.5Sn titanium pipes, covering material properties, manufacturing processes, applications, sizes, parameter tables, and market trends.

Introduction

Grade 6 Ti-5Al-2.5Sn is a titanium alloy that contains 5% aluminum and 2.5% tin. It is primarily used in the aerospace industry due to its good weldability, high strength-to-weight ratio, and resistance to fatigue and crack propagation. This alloy is particularly valuable in environments where high strength and low weight are critical.

Material Properties

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.0 |

| Tin (Sn) | 2.5 |

| Other elements (max) | 0.3 |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 895 MPa (130 ksi) |

| Yield Strength | 825 MPa (120 ksi) |

| Elongation | 10% |

| Modulus of Elasticity | 113.8 GPa (16.5 x 10^6 psi) |

| Density | 4.48 g/cm³ |

| Hardness (Rockwell B) | 95 |

| Thermal Conductivity | 6.7 W/m·K |

| Coefficient of Expansion | 8.6 µm/m·K |

Physical Properties

- Corrosion Resistance: Excellent resistance to a wide range of corrosive environments, including seawater.

- High Temperature Performance: Maintains strength and stability at elevated temperatures up to 400°C (752°F).

- Fatigue Resistance: High resistance to fatigue and crack growth, making it suitable for cyclic loading applications.

Manufacturing Processes

Tube Forming

- Extrusion: Titanium billets are heated and extruded through a die to form tubes.

- Cold Working: Tubes are cold worked to achieve the desired mechanical properties and dimensions.

- Annealing: Heat treatment is applied to relieve stresses and improve ductility.

Welding

- TIG (Tungsten Inert Gas) Welding: Commonly used for welding Grade 6 Ti-5Al-2.5Sn due to its precision and control.

- Electron Beam Welding: Employed for high-quality welds in critical applications.

Surface Treatment

- Pickling: Removes surface oxides and impurities to improve corrosion resistance.

- Passivation: Enhances the natural oxide layer to further protect against corrosion.

Applications

Aerospace

- Aircraft Structural Components: Used in airframes, landing gear, and other structural elements.

- Jet Engine Parts: Ideal for compressor blades and other components exposed to high temperatures and stresses.

Marine

- Offshore Oil and Gas: Utilized in risers, pipelines, and subsea components due to excellent corrosion resistance.

- Shipbuilding: Employed in hulls, propellers, and other critical parts.

Medical

- Implants and Prosthetics: Biocompatibility and high strength make it suitable for medical implants and prosthetics.

- Surgical Instruments: Used in the manufacture of durable and corrosion-resistant surgical tools.

Industrial

- Chemical Processing: Applied in heat exchangers, reactors, and piping systems handling corrosive substances.

- Power Generation: Used in turbine blades and other components exposed to high temperatures and harsh environments.

Sizes and Standards

Standard Sizes

Titanium pipes are available in various sizes, typically specified by outer diameter (OD) and wall thickness.

| Nominal Pipe Size (NPS) | Outer Diameter (OD) | Wall Thickness |

|---|---|---|

| 1/4″ | 13.72 mm (0.540″) | 1.65 mm (0.065″) |

| 1/2″ | 21.34 mm (0.840″) | 2.11 mm (0.083″) |

| 1″ | 33.40 mm (1.315″) | 2.77 mm (0.109″) |

| 2″ | 60.33 mm (2.375″) | 3.91 mm (0.154″) |

| 4″ | 114.30 mm (4.500″) | 6.02 mm (0.237″) |

Standards

- ASTM B338: Standard specification for seamless and welded titanium and titanium alloy tubes for condensers and heat exchangers.

- AMS 4940: Aerospace material specification for Ti-5Al-2.5Sn alloy.

Parameter Tables

Mechanical Properties

| Parameter | Value |

|---|---|

| Tensile Strength | 895 MPa (130 ksi) |

| Yield Strength | 825 MPa (120 ksi) |

| Elongation | 10% |

| Modulus of Elasticity | 113.8 GPa (16.5 x 10^6 psi) |

| Density | 4.48 g/cm³ |

Thermal and Physical Properties

| Parameter | Value |

|---|---|

| Thermal Conductivity | 6.7 W/m·K |

| Coefficient of Expansion | 8.6 µm/m·K |

| Melting Point | 1660°C (3020°F) |

| Specific Heat Capacity | 0.523 J/g·K |

Market Trends

Demand Drivers

- Aerospace Industry Growth: Increasing production of commercial and military aircraft boosts demand for high-performance materials like Grade 6 titanium.

- Marine Applications: Expansion of offshore oil and gas exploration drives the need for corrosion-resistant materials.

- Medical Industry: Rising demand for implants and surgical instruments fuels growth.

Regional Analysis

- North America: Significant demand due to the presence of major aerospace manufacturers and advanced medical device companies.

- Europe: Growth driven by aerospace and automotive industries.

- Asia-Pacific: Rapid industrialization and expansion in aerospace and marine sectors.

Challenges

- High Cost: Titanium alloys are more expensive than other materials, which can limit their use in cost-sensitive applications.

- Processing Difficulties: Titanium’s reactivity and high melting point pose challenges in manufacturing and welding.

Conclusion

Grade 6 Ti-5Al-2.5Sn titanium pipes offer exceptional performance in demanding applications due to their high strength, excellent corrosion resistance, and good weldability. These properties make them ideal for aerospace, marine, medical, and industrial uses. Despite challenges such as high cost and processing difficulties, the demand for titanium pipes continues to grow, driven by the needs of high-performance applications and advancements in manufacturing technologies.

References

- ASTM Standards for Titanium and Titanium Alloys

- Aerospace Material Specifications (AMS)

- Industry reports on titanium market trends and forecasts

- Technical literature on titanium alloy properties and applications

This comprehensive analysis provides a detailed understanding of Grade 6 Ti-5Al-2.5Sn titanium pipes, covering material properties, manufacturing processes, applications, sizes, and market trends.

Future Outlook

Technological Advancements

- Additive Manufacturing: The adoption of 3D printing technology is expected to revolutionize the manufacturing of titanium components, enabling more complex geometries and reducing material wastage.

- Improved Welding Techniques: Advances in welding technology, such as laser welding and friction stir welding, will enhance the quality and efficiency of titanium pipe fabrication.

- Surface Coatings: Development of advanced coatings and surface treatments will further improve the corrosion resistance and wear properties of titanium alloys.

Sustainability

- Recycling and Reuse: Increased focus on sustainability will drive efforts to recycle titanium scrap and develop processes for reusing titanium components, thereby reducing the environmental impact.

- Energy Efficiency: Research into more energy-efficient production methods will help lower the overall cost and carbon footprint of titanium manufacturing.

Market Expansion

- Emerging Markets: Growth of aerospace and industrial sectors in emerging economies presents significant opportunities for market expansion.

- New Applications: Exploration of new applications, such as in the automotive industry for lightweight, high-strength components, will drive additional demand for titanium alloys.

Acknowledgments

Special thanks to the following contributors and resources that provided valuable insights and data for this analysis:

- Material Science Experts: For their technical input on titanium alloy properties and applications.

- Industry Reports: For market trends and forecasts.

- Technical Literature: For detailed information on manufacturing processes and standards.

Appendices

Appendix A: Detailed Chemical Composition

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.0 |

| Tin (Sn) | 2.5 |

| Oxygen (O) | ≤ 0.2 |

| Nitrogen (N) | ≤ 0.05 |

| Carbon (C) | ≤ 0.08 |

| Hydrogen (H) | ≤ 0.015 |

| Iron (Fe) | ≤ 0.30 |

| Other elements | ≤ 0.10 each |

### Appendix C: Conversion Tables #### Length | **Metric (mm)** | **Imperial (inches)** | |-----------------|-----------------------| | 1 mm | 0.03937 inches | | 10 mm | 0.3937 inches | | 100 mm | 3.937 inches | | 1000 mm | 39.37 inches | #### Weight | **Metric (kg)** | **Imperial (lbs)** | |-----------------|-----------------------| | 1 kg | 2.20462 lbs | | 10 kg | 22.0462 lbs | | 100 kg | 220.462 lbs | | 1000 kg | 2204.62 lbs | ### Appendix D: Abbreviations - **Ti**: Titanium - **Al**: Aluminum - **Sn**: Tin - **NPS**: Nominal Pipe Size - **OD**: Outer Diameter - **ASTM**: American Society for Testing and Materials - **AMS**: Aerospace Material Specification ## Further Reading 1. **"Titanium: A Technical Guide" by Matthew J. Donachie**: An in-depth resource on titanium and its alloys, covering properties, processing, and applications. 2. **"Titanium Alloys: An Atlas of Structures and Fracture Features" by Andrey B. Vasiliev**: Detailed atlas providing insights into the microstructures and fracture characteristics of titanium alloys. 3. **"Advanced Titanium Alloys" by Yoshiki Oshida**: Comprehensive overview of advanced titanium alloys, focusing on their development, properties, and applications. By providing this detailed analysis, we hope to offer a comprehensive understanding of Grade 6 Ti-5Al-2.5Sn titanium pipes, highlighting their significance, manufacturing, and wide-ranging applications.