ASTM B644 C71520 Seamless Nickel Pipe

July 28, 2024

3PE Coated Pipe Installation and Construction – Customer Case Study

August 3, 2024Incoloy 825 (UNS N08825) Steel Pipe

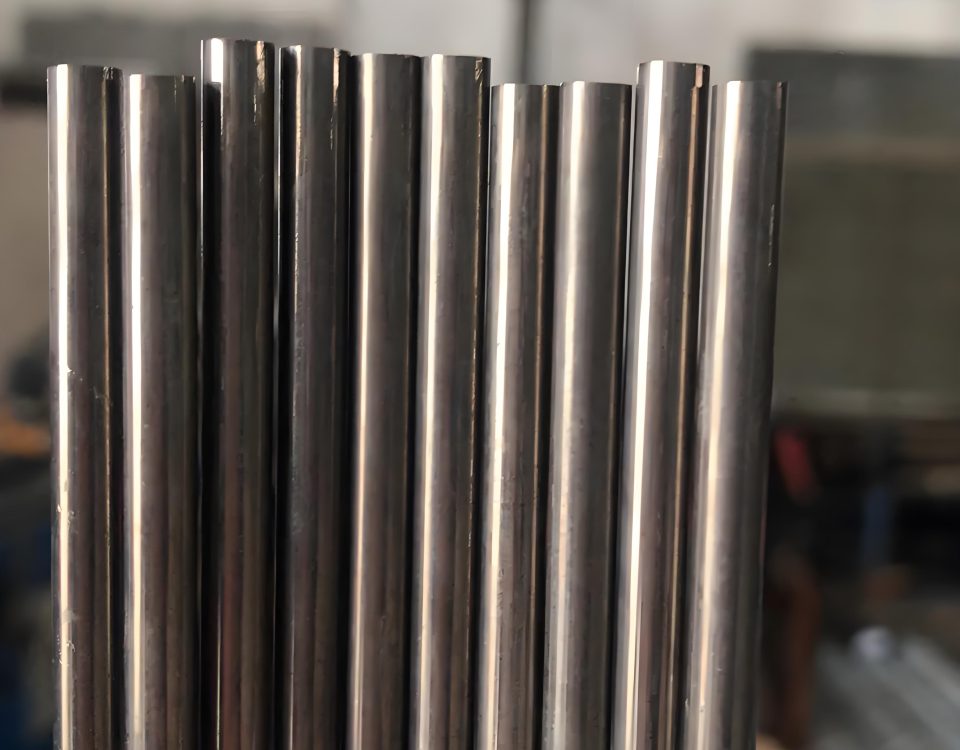

Introduction

Incoloy 825, also known as Alloy 825, is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. This alloy is known for its excellent resistance to both reducing and oxidizing acids, stress-corrosion cracking, and localized attack such as pitting and crevice corrosion. It is widely used in various industries due to its robust performance in harsh environments.

Chemical Composition

The chemical composition of Incoloy 825 is carefully balanced to provide its excellent corrosion resistance and mechanical properties. Here’s a detailed breakdown:

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 38.0 – 46.0 |

| Chromium (Cr) | 19.5 – 23.5 |

| Iron (Fe) | 22.0 min |

| Molybdenum (Mo) | 2.5 – 3.5 |

| Copper (Cu) | 1.5 – 3.0 |

| Titanium (Ti) | 0.6 – 1.2 |

| Manganese (Mn) | 1.0 max |

| Carbon (C) | 0.05 max |

| Silicon (Si) | 0.5 max |

| Sulfur (S) | 0.03 max |

Mechanical Properties

Incoloy 825 exhibits a combination of high strength and good ductility. Key mechanical properties include:

| Property | Value |

|---|---|

| Tensile Strength | 85 ksi (586 MPa) min |

| Yield Strength | 35 ksi (241 MPa) min |

| Elongation | 30% min |

| Hardness | 85 HRB max |

Physical Properties

The physical properties of Incoloy 825 make it suitable for high-temperature and corrosive environments:

| Property | Value |

|---|---|

| Density | 8.14 g/cm³ |

| Melting Point | 1370 – 1400°C (2500 – 2550°F) |

| Specific Heat | 0.103 Btu/lb·°F (431 J/kg·K) |

| Electrical Resistivity | 1.078 µΩ·m |

| Thermal Conductivity | 10.8 W/m·K |

| Coefficient of Expansion | 13.5 µm/m·°C (20-100°C) |

Manufacturing Processes

The production of Incoloy 825 pipes involves meticulous manufacturing processes to ensure quality and performance:

- Melting and Casting: Raw materials are melted in an electric arc furnace or induction furnace. The molten metal is cast into ingots or billets.

- Hot Working: The billets are hot worked to form bars, rods, or other shapes.

- Cold Working: Pipes are cold worked through drawing or pilgering to achieve precise dimensions and improved mechanical properties.

- Annealing: The cold-worked pipes are annealed to relieve internal stresses and enhance ductility.

- Final Processing: Pipes are straightened, cut to length, and surface finished.

- Inspection and Testing: Conducting rigorous inspections and tests, including nondestructive testing, to ensure compliance with specifications.

Applications

Incoloy 825 pipes are used in various industries due to their high resistance to corrosion and excellent mechanical properties. Common applications include:

Chemical Processing

- Heat Exchangers: Tubing in heat exchangers handling corrosive chemicals.

- Process Piping: Piping systems in chemical plants where corrosion resistance is critical.

Oil and Gas Industry

- Offshore Drilling: Piping and tubing for offshore platforms and subsea installations.

- Production Equipment: Components in oil and gas extraction and processing.

Pollution Control

- Scrubbers: Piping and components in flue-gas desulfurization systems.

- Industrial Waste: Handling and processing of waste in pollution control systems.

Nuclear Industry

- Fuel Reprocessing: Equipment for handling and processing nuclear fuel.

- Waste Management: Containers and pipes for nuclear waste management.

Specifications and Standards

Incoloy 825 pipes are manufactured to meet specific standards and specifications ensuring their quality and performance:

- ASTM B423: Standard specification for nickel-iron-chromium-molybdenum-copper alloy (UNS N08825) seamless pipe and tube.

- ASME SB423: American Society of Mechanical Engineers standard for seamless pipes.

- DIN 17744: German standard for nickel-iron-chromium-molybdenum-copper alloys, including UNS N08825.

Availability and Sizes

Incoloy 825 pipes are available in various sizes and forms to meet specific project requirements. Common sizes include:

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | Wall Thickness | Weight (lb/ft) |

|---|---|---|---|

| 1/2″ | 0.840″ | 0.109″ | 0.84 |

| 1″ | 1.315″ | 0.133″ | 1.66 |

| 2″ | 2.375″ | 0.154″ | 3.53 |

| 4″ | 4.500″ | 0.237″ | 10.53 |

Advantages of Incoloy 825

- Corrosion Resistance: Excellent resistance to a variety of corrosive environments.

- Mechanical Strength: High tensile and yield strength for demanding applications.

- Thermal Stability: Maintains properties at elevated temperatures.

- Longevity: Long service life in harsh environments, reducing maintenance costs.

- Versatility: Suitable for a wide range of applications across multiple industries.

Conclusion

Incoloy 825 (UNS N08825) steel pipes offer exceptional corrosion resistance, mechanical strength, and durability, making them ideal for use in harsh environments across various industries. Their versatility and reliability ensure their importance in chemical processing, oil and gas, pollution control, and the nuclear industry. Selecting the right material and ensuring compliance with relevant standards is crucial for the success of any project involving these high-performance pipes.