Monel 404 UNS N04404 Alloy steel pipe | DIN W. Nr. 2.4867

March 31, 2024

Long Radius Elbow, Short Radius Elbow, LR & SR Elbow

April 7, 2024The Ultimate Guide to ASTM B861, B862, and B338 Titanium Pipes and Tubes

Introduction

In the world of industrial applications, titanium has become a highly sought-after material due to its exceptional corrosion resistance and high strength-to-weight ratio. Titanium pipes and tubes are widely used in various industries, including aerospace, chemical processing, oil and gas, and marine. In this comprehensive guide, we will explore the specifications and applications of ASTM B861, B862, and B338 titanium pipes and tubes. So, let’s dive in!

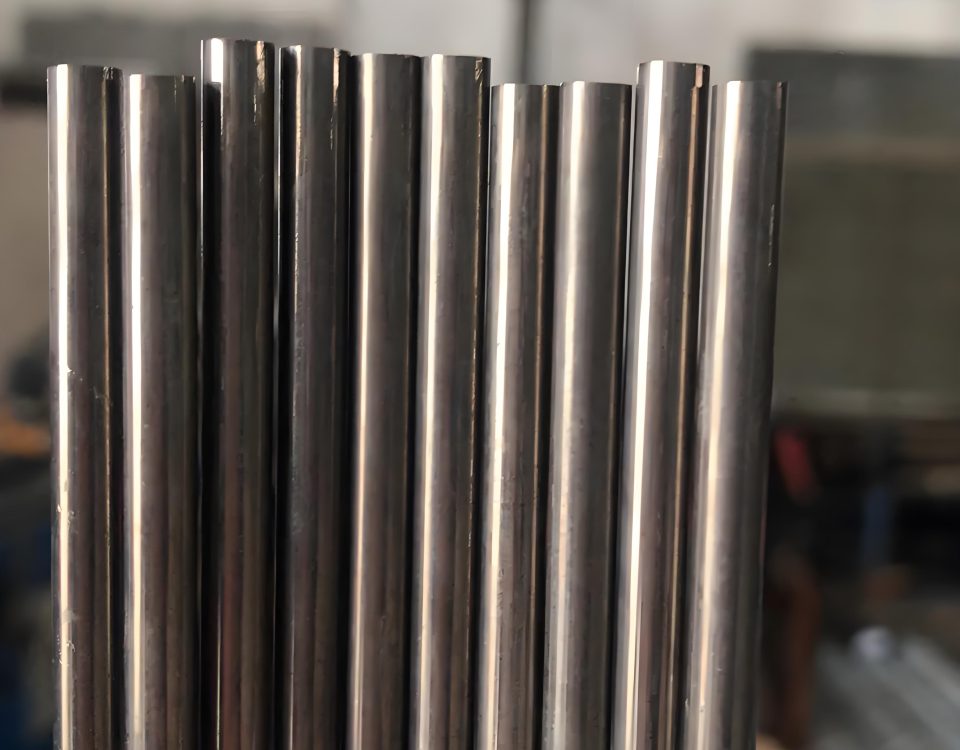

ASTM B861: Titanium and Titanium Alloy Seamless Pipes

ASTM B861 covers the manufacturing of seamless pipes made from titanium and titanium alloys. These pipes are specifically designed for general corrosion resisting and elevated temperature service. The standard includes a wide range of titanium grades, including Grades 1, 2, 2H, 3, 5, 7, 7H, 9, 11, 12, 13, 14, 15, 16, 16H, 17, 18, 19, 20, 21, 23, 24, 25, 26, 26H, 27, 28, 29, 33, 34, 35, 36, 37, and 38.

Manufacturing and End Types

ASTM B861 seamless pipes can be furnished with butt welding ends, plain ends, or threaded ends, depending on the specific requirements of the application. The wall thickness of the pipes conforms to either ASME B36.10 or ASME B36.19 standards.

Heat Treatment

The heat treatment process for ASTM B861 seamless pipes depends on the specific grade. Cold worked pipes are required to undergo heat treatment at a temperature of not less than 1000°F (538°C). On the other hand, hot worked pipes finishing above 1400°F (760°C) do not require further heat treatment.

Condition of Supply

The condition of supply for ASTM B861 seamless pipes varies based on the grade. Grades 5, 23, 24, 25, 29, 35, and 36 may be supplied in either annealed or aged condition. Grades 9, 18, 28, and 38 may be supplied in cold-worked and stress-relieved or annealed condition. Grades 9, 18, 23, 28, and 29 may be supplied in transformed-beta condition. Grades 19, 20, and 21 may be supplied in solution-treated or solution-treated and aged condition.

Seamless Ti Tube ASTM B861

ASME SB 861 / ASTM B861,Standard Specification for Titanium and Titanium Alloy Seamless Pipe,ASTM B861 Grade 2 titanium pipe is mostly used for Heat Exchangers in chemical processing due to titanium’s ultra corrosion resistance.

| ASTM B861 | Grade |

| Commercially Pure(CP) Grades | Grade 1,Grade 2,Grade 3,Grade 7,Grade 11 (CP Ti-0.15Pd),Grade 16,Grade 17,Grade 26,Grade 27 |

| Titanium Based Alloys Grades | Grade 5,Grade 9 ( Ti 3Al-2.5V),Grade 12 (Ti-0.3-Mo-0.8Ni),Grade 19 (Ti Beta C),Grade 23 (Ti 6Al-4V ELI),Grade 28 |

ASTM B861 grade2 Chemical composition

| Titanium (Ti) | Ni | C | H | Fe | O | Total |

| Balance | 0.03 max | 0.08 | 0.015 | 0.30max | 0.25 | 0.0-0.10 |

ASTM B861 grade2 Physical Properties

| Mechanical Property | Value |

| Proof Stress | 275-450 MPa |

| Tensile Strength | 345 Min MPa |

| Elongation A50 mm | 20 Min % |

Size of supply:

SHEW-E stock and sell ASTM A861 titanium tubing in size range outside diameter 3-114 mm ,wall thicknesses from 0.2 to 30 mm

ASTM B862: Titanium and Titanium Alloy Welded Pipes

ASTM B862 covers the manufacturing of welded pipes made from titanium and titanium alloys. Similar to ASTM B861, this standard also includes a wide range of titanium grades, including Grades 1, 2, 2H, 3, 5, 7, 7H, 9, 11, 12, 13, 14, 15, 16, 16H, 17, 18, 19, 20, 21, 23, 24, 25, 26, 26H, 27, 28, 29, 33, 34, 35, 37, and 38.

Manufacturing and Filler Metal

The Ti or Ti alloy welded pipes specified in ASTM B862 are made from annealed flat-rolled products using a welding process. If filler metal is used, it shall be produced to AWS A5.16 employing the ER Ti-X grade listed in Table 5 of the standard.

Condition of Supply

The condition of supply for ASTM B862 welded pipes depends on the grade. Grades 1, 2, 2H, 7, 7H, 11, 13, 14, 16, 16H, 17, 26H, 33, and 37 can be furnished as welded or annealed. Grades 3, 12, 15, and 34 are supplied as annealed. Grades 5, 23, 24, 25, and 35 are supplied as annealed or aged. Grades 9, 18, and 38 are supplied as annealed. Grades 19, 20, and 21 are supplied as solution treated or solution treated and aged.

Chemical Composition Of ASTM B862 Grade 2 Titanium Welded Pipe

| ELEMENT | Chemical Composition % | ||||||||

| GRADE 1 | GRADE 2 | GRADE 3 | GRADE 5 | GRADE 7 | GRADE 9 | GRADE 11 | GRADE 12 | GRADE 23 | |

| Nitrogen, max | 0.03 | 0.03 | 0.05 | 0.05 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| Carbon, max | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

| Hydrogen, max | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.0125 |

| Iron, max | 0.20 | 0.30 | 0.30 | 0.40 | 0.30 | 0.25 | 0.20 | 0.30 | 0.25 |

| Oxygen, max | 0.18 | 0.25 | 0.35 | 0.20 | 0.25 | 0.15 | 0.18 | 0.25 | 0.13 |

| Aluminum | … | … | … | 5.5-6.75 | … | 2.5-3.5 | … | … | 5.5-6.5 |

| Vanadium | … | … | … | 3.5-4.5 | … | 2.0-3.0 | … | … | 3.5-4.5 |

| Tin | … | … | … | … | … | … | … | … | … |

| Ruthenium | … | … | … | … | … | … | … | … | … |

| Palladium | … | … | … | … | 0.12-0.25 | … | 0.12-0.25 | … | … |

| Molybdenum | … | … | … | … | … | … | … | 0.2-0.4 | … |

| Chromium | … | … | … | … | … | … | … | … | … |

| Nickel | … | … | … | … | … | … | … | 0.6-0.9 | … |

| Niobium | … | … | … | … | … | … | … | … | … |

| Ziconium | … | … | … | … | … | … | … | … | … |

| Silicon | … | … | … | … | … | … | … | … | … |

| Residuals, max each | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Residuals, max total | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Titanium | balance | balance | balance | balance | balance | balance | balance | balance | balance |

Tensile Strength Of Titanium Welded Pipe

| Grade | Tensile Strength, min | Yiel Strength (0.2% Offset) | Elongation 2 in. or 50 mm | |||||

| min | max | |||||||

| Ksi | (Mpa) | Ksi | (Mpa) | Ksi | (Mpa) | gage length min % | ||

| Grade 1 | 35 | (240) | 25 | (170) | 45 | (310) | 24 | |

| Grade 2 | 50 | (345) | 40 | (275) | 65 | (450) | 20 | |

| Grade 3 | 65 | (450) | 55 | (380) | 80 | (550) | 18 | |

| Grade 5 | 130 | (895) | 120 | (828) | … | … | 10 | |

| Grade 7 | 50 | (345) | 40 | (275) | 65 | (450) | 20 | |

| Grade 9 | 90 | (620) | 70 | (483) | 45 | … | 15 | |

| Grade 11 | 35 | (240) | 25 | (170) | … | (310) | 24 | |

| Grade 12 | 70 | (483) | 50 | (345) | … | … | 18 | |

| Grade 23 | 120 | (828) | 110 | (759) | … | … | 10 | |

| Grade | GB | ASTM | Russia | ||

| Pure Titanium | TA1 | GR1 | BT1-00 | ||

| TA2 | GR2 | BT1-0 | |||

| TA3 | GR3 | BT1-0 | |||

| TA4 | GR4 | BT1-0 | |||

| Titanium Alloy | TA7 | GR6 | BT5-1 | ||

| TA7ELI | GR6 | BT5-1 | |||

| TA9 | |||||

| TA10 | GR12 | ||||

| TA15 | BT20 | ||||

| TA18 | GR9 | ||||

| TA19 | Ti-6242S | ||||

| TC3 | GRF-5 | BT6C | |||

| TC4 | GR5 | BT6 | |||

| TC4ELI | GR23 | ||||

| TC6 | BT3-1 | ||||

| TC11 | BT9 | ||||

| TC17 | |||||

| TC18 | BT22 | ||||

| TC19 | Ti-6246 | ||||

| TC20 | |||||

| TC25 | |||||

| TB2 | |||||

| TB6 | Ti-10-2-3 | ||||

| 7715D | |||||

| STi80 | |||||

ASTM B338: Titanium and Titanium Alloy Seamless and Welded Tubes

ASTM B338 covers the manufacturing of seamless and welded tubes made from titanium and titanium alloys. These tubes are primarily used in surface condensers, evaporators, and heat exchanges. The standard includes a wide range of titanium grades, including Grades 1, 2, 2H, 3, 7, 7H, 9, 11, 12, 13, 14, 15, 16, 16H, 17, 18, 26, 26H, 27, 28, 30, 31, 33, 34, 35, 36, 37, and 38.

ASTM B338 Titanium Tube

ASTM B338 is a standard for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers.ASTM B338 Seamless Tubes offer roughly 20% more working pressure than welded tube and are chosen over welded titanium tube when high corrosion resistance is needed.

| ASTM B388 | Grade |

| Unalloyed Titanium | Grade 1,Grade 2,Grade 3,Grade 7,Grade 11 (CP Ti-0.15Pd),Grade 16,Grade 17,Grade 26,Grade 27 |

| Titanium Based Alloys | Grade 5,Grade 9 ( Ti 3Al-2.5V),Grade 12 (Ti-0.3-Mo-0.8Ni),Grade 19 (Ti Beta C),Grade 23 (Ti 6Al-4V ELI),Grade 28 |

* ASTM B 388 Grade 1 and Grade 2 are the commonly used material in Unalloyed Titanium family,Grade 5 alloy is the most commercially available of all titanium alloys.

Size And Tolerances:

SHEW-E stock and sell ASTM A338 titanium tubing in size range outside diameter 9.53–38.1 mm (3/8–1½ in.),wall thicknesses from 0.7 to 5 mm (0.0275 to 0.1968 in.).

| OD, mm | Tolerances OD, mm | WT min wall % | Length mm |

| < 25.4 | ±0.102 | +20/-0 | 4000-9000 |

| 25.4-38.1 | ±0.127 | +20/-0 | 4000-15000 |

* Tolerances for OD < 15.9 or > 38.1 – or closer tolerances – after special agreement.

* The titanium tubes are delivered in straight lengths or as U-bent tubes.

Manufacturing Process

Seamless tubes specified in ASTM B338 are made from hollow billets using a cold reducing or cold drawing process. These tubes are produced with a continuous periphery in all stages of manufacturing operations. On the other hand, welded tubes are made from annealed, flat-rolled products using an automatic arc-welding process or other welding methods.

Heat Treatment and Filler Material

Welded tubing specified in ASTM B338 is required to undergo heat treatment by at least a stress relief after forming and welding. The use of filler material is not permitted in the manufacturing process.

Condition of Supply

The condition of supply for ASTM B338 tubes varies based on the grade. Grades 1, 2, 2H, 7, 7H, 11, 13, 14, 16, 16H, 17, 26H, 33, and 37 can be furnished as welded or annealed. Grades 3, 12, 15, and 34 are supplied as annealed. Grades 5, 23, 24, 25, and 35 are supplied as annealed or aged. Grades 9, 18, and 38 are supplied as annealed. Grades 19, 20, and 21 are supplied as solution treated or solution treated and aged.

Applications of ASTM B861, B862, and B338 Titanium Pipes and Tubes

Titanium pipes and tubes manufactured according to ASTM B861, B862, and B338 standards find extensive applications in various industries. Some of the common applications include:

- Aerospace industry: Titanium pipes and tubes are used in aircraft structures, engine components, and hydraulic systems due to their high strength-to-weight ratio and corrosion resistance.

- Chemical processing industry: Titanium pipes and tubes are ideal for handling corrosive chemicals and acids, making them suitable for chemical processing plants.

- Oil and gas industry: Titanium pipes and tubes are used in offshore platforms, subsea pipelines, and oil refineries due to their resistance to seawater corrosion and high temperatures.

- Marine industry: Titanium pipes and tubes are used in shipbuilding and offshore structures due to their resistance to saltwater corrosion and biofouling.

- Medical industry: Titanium pipes and tubes are used in medical implants, such as joint replacements and dental implants, due to their biocompatibility and corrosion resistance.

Frequently Asked Questions (FAQ)

Q1: What are the different grades of titanium covered by ASTM B861, B862, and B338?

A1: ASTM B861, B862, and B338 cover a wide range of titanium grades, including Grades 1, 2, 2H, 3, 5, 7, 7H, 9, 11, 12, 13, 14, 15, 16, 16H, 17, 18, 19, 20, 21, 23, 24, 25, 26, 26H, 27, 28, 29, 33, 34, 35, 36, 37, and 38.

Q2: What is the difference between seamless and welded titanium pipes and tubes?

A2: Seamless pipes and tubes are manufactured from a single piece of hollow billet, while welded pipes and tubes are made by joining multiple pieces of flat-rolled products using a welding process.

Q3: What is the heat treatment process for titanium pipes and tubes?

A3: The heat treatment process for titanium pipes and tubes depends on the specific grade. Cold worked pipes require heat treatment at a temperature of not less than 1000°F (538°C), while hot worked pipes finishing above 1400°F (760°C) do not require further heat treatment.

Q4: Can filler material be used in the manufacturing of titanium pipes and tubes?

A4: In the case of welded titanium pipes and tubes, the use of filler material is not permitted. The welding process involves joining the annealed flat-rolled products without the need for additional filler material.

Q5: What are the typical applications of titanium pipes and tubes?

A5: Titanium pipes and tubes find applications in various industries, including aerospace, chemical processing, oil and gas, marine, and medical. They are used for their corrosion resistance, high strength-to-weight ratio, and biocompatibility.

Conclusion

ASTM B861, B862, and B338 are essential standards for the manufacturing of titanium pipes and tubes. These pipes and tubes offer exceptional corrosion resistance and high strength, making them suitable for a wide range of applications. Whether it’s for aerospace, chemical processing, oil