ASTM A815 SAF250 / UNS S32750 Super Duplex Buttweld Pipe Fitting

December 17, 2024

Butt Weld Seamless Steel Concentric and Eccentric Reducers

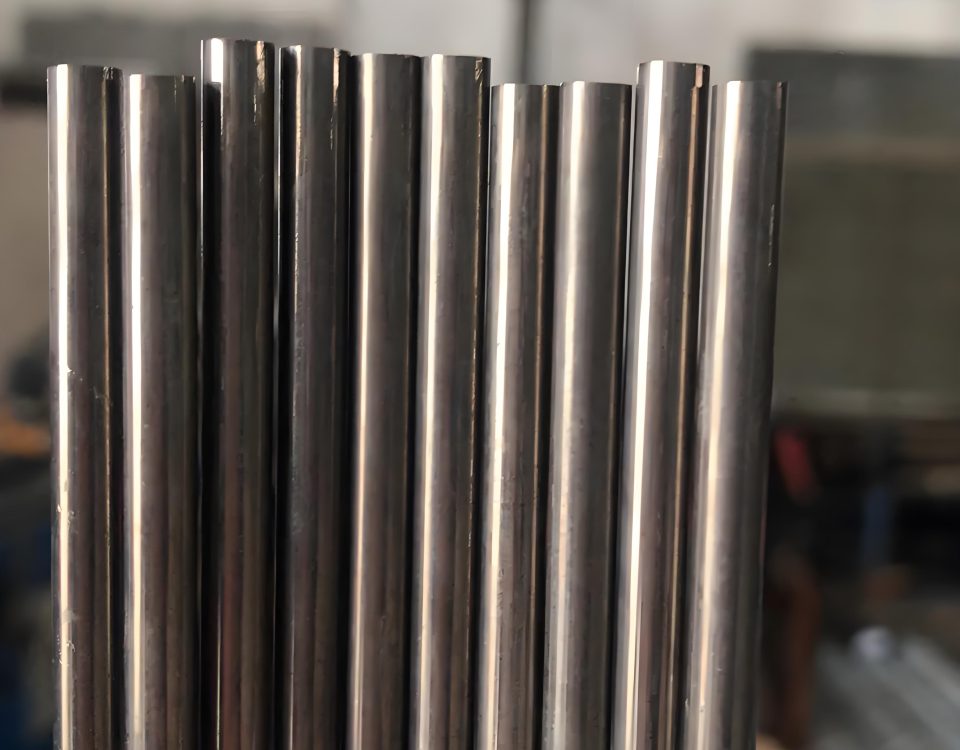

December 29, 2024The Ultimate Guide to UNS N04401 Monel 401 Alloy Steel Tube

Monel 401 is a nickel-copper alloy widely used for its excellent mechanical properties, resistance to corrosion, and thermal conductivity. UNS N04401 Monel 401 alloy steel tube is a preferred choice for industries that demand superior durability, high performance, and resistance to harsh conditions. Whether you’re involved in marine engineering, chemical processing, or electronics, understanding this material is essential for making informed decisions about your industrial needs.

In this guide, we’ll dive deep into the properties, applications, and benefits of UNS N04401 Monel 401 alloy steel tubes.

What is UNS N04401 Monel 401 Alloy Steel Tube?

The UNS N04401 Monel 401 is a high-performance alloy composed primarily of nickel and copper. It is designed to combine the exceptional strength of nickel with the corrosion resistance of copper, making it a durable and versatile option for industries operating in demanding environments. The Monel 401 alloy is specifically known for its electrical and thermal conductivity, which makes it suitable for specialized applications such as thermocouples and electrical connectors.

With its unique composition and robust physical properties, the Monel 401 alloy stands out as a reliable material for various industrial purposes.

Key Properties of UNS N04401 Monel 401 Alloy Steel Tube

1. Corrosion Resistance

Monel 401 alloy provides outstanding resistance to corrosion, especially in marine and chemical environments. This makes it ideal for applications where exposure to seawater or chemical agents is inevitable.

2. High Thermal Conductivity

The alloy’s excellent thermal conductivity ensures its suitability for heat exchangers, condensers, and other equipment that requires efficient heat transfer.

3. Durability and Strength

With a robust nickel-copper composition, UNS N04401 Monel 401 offers exceptional strength and durability, even in high-stress applications.

4. Electrical Conductivity

One of the standout features of Monel 401 is its high electrical conductivity, making it a prime choice for electronic components and connectors.

5. Resistance to Deformation

The alloy maintains its structural integrity under pressure, temperature fluctuations, and mechanical stress.

6. Magnetic Properties

Monel 401 alloy exhibits magnetic properties under certain conditions, making it useful in electrical and magnetic applications.

Chemical Composition of Monel 401 Alloy

| Element | Percentage |

|---|---|

| Nickel (Ni) | 42% – 50% |

| Copper (Cu) | 47% – 52% |

| Iron (Fe) | ≤ 1.0% |

| Manganese (Mn) | ≤ 0.5% |

| Carbon (C) | ≤ 0.3% |

This balanced composition enhances its corrosion resistance, conductivity, and overall performance.

Physical Properties of UNS N04401 Monel 401 Alloy

| Property | Value | Unit |

|---|---|---|

| Density | 8.80 | g/cm³ |

| Melting Point | 1350–1400 | °C |

| Electrical Resistivity | 51.6 | µΩ·cm |

| Thermal Conductivity | 30.4 | W/m·K |

| Specific Heat Capacity | 0.427 | J/g·K |

| Magnetic Properties | Slightly Magnetic | – |

Mechanical Properties of UNS N04401 Monel 401 Alloy

| Property | Value | Unit |

|---|---|---|

| Tensile Strength (Ultimate) | 380-550 | MPa |

| Yield Strength (0.2% offset) | 170-240 | MPa |

| Elongation at Break | 40 | % |

| Hardness (Brinell) | 100-140 | HB |

| Modulus of Elasticity | 170 | GPa |

| Poisson’s Ratio | 0.32 | – |

These properties showcase why UNS N04401 Monel 401 alloy tubes are valued in applications demanding durability, thermal stability, and resistance to corrosion

Applications of UNS N04401 Monel 401 Alloy Steel Tube

1. Marine Engineering

The exceptional corrosion resistance of Monel 401 makes it a reliable choice for marine applications, including shipbuilding, seawater piping, and underwater cabling.

2. Chemical Processing

The material’s ability to withstand exposure to harsh chemicals makes it suitable for use in chemical reactors, storage tanks, and processing equipment.

3. Electrical and Electronic Components

Monel 401 is widely used in thermocouples, electrical connectors, and resistors due to its excellent electrical conductivity and magnetic properties.

4. Aerospace Industry

In the aerospace sector, Monel 401 tubes are used in heat exchangers, fuel systems, and other components where durability and thermal conductivity are critical.

5. Oil and Gas Industry

The alloy’s resistance to corrosion and ability to perform in extreme conditions make it ideal for pipelines, valves, and offshore drilling components.

6. Heat Exchangers and Condensers

The high thermal conductivity of Monel 401 allows it to be used effectively in heat transfer equipment, ensuring efficient energy transfer in industrial processes.

Advantages of Using UNS N04401 Monel 401 Alloy Steel Tube

1. Longevity

The durability of Monel 401 ensures that it can withstand years of usage in harsh environments, reducing maintenance costs.

2. Versatility

Its wide range of properties makes it suitable for multiple industries, from electronics to oil and gas.

3. Enhanced Safety

With its resistance to chemical corrosion and high temperatures, the alloy enhances safety in critical applications.

4. Cost-Effectiveness

Although Monel 401 may have a higher initial cost, its longevity and low maintenance requirements provide significant long-term savings.

How to Select the Right UNS N04401 Monel 401 Alloy Steel Tube

When choosing a Monel 401 alloy tube, consider the following factors:

- Operating Environment: Assess whether the material will be exposed to corrosive agents or extreme temperatures.

- Size and Specifications: Ensure the tube’s dimensions and specifications meet your application’s requirements.

- Certifications: Verify that the material complies with industry standards and certifications.

- Supplier Reliability: Source the alloy from reputable manufacturers to guarantee quality.

Maintenance Tips for UNS N04401 Monel 401 Alloy Steel Tube

To maximize the lifespan of Monel 401 alloy tubes:

- Regularly inspect for signs of wear, corrosion, or damage.

- Clean the tubes periodically to prevent the buildup of debris or contaminants.

- Follow manufacturer guidelines for maintenance and usage.

- Store the tubes in a dry, clean environment to prevent premature corrosion.

UNS N04401 Monel 401 Alloy Steel Tube: The Ideal Choice for High-Performance Applications

When it comes to selecting materials for demanding industrial applications, Monel 401 alloy steel tubes stand out for their exceptional performance and reliability. Its unique properties, such as corrosion resistance, high conductivity, and durability, make it an indispensable material for industries like marine engineering, electronics, and chemical processing.

By understanding the properties, applications, and benefits of UNS N04401 Monel 401, you can ensure that you are using the best possible material for your specific needs.

FAQs

What is the primary composition of UNS N04401 Monel 401 alloy?

Monel 401 is primarily composed of 42-50% nickel and 47-52% copper, along with trace elements like iron, manganese, and carbon.

What industries commonly use UNS N04401 Monel 401 alloy steel tubes?

Industries such as marine engineering, chemical processing, electronics, aerospace, and oil and gas commonly use Monel 401 for its durability and resistance to harsh conditions.

How does UNS N04401 Monel 401 alloy perform in marine environments?

The alloy provides exceptional corrosion resistance in seawater, making it an ideal material for shipbuilding, underwater cabling, and marine piping systems.

Is Monel 401 suitable for high-temperature applications?

Yes, Monel 401 performs well under high temperatures, retaining its strength and structural integrity in extreme conditions.

What are the key benefits of using Monel 401 alloy tubes?

The benefits include corrosion resistance, durability, thermal and electrical conductivity, and low maintenance requirements.

Where can I source UNS N04401 Monel 401 alloy steel tubes?

Always choose reputable manufacturers or suppliers with certifications to ensure the material’s quality and authenticity.