B163 UNS N06600 Nickel Alloy Steel Pipe | ASME SB163 600

May 21, 2024

B704 UNS N06625 UNS N08825 Nickel Alloy Steel Pipe

May 25, 2024UNS N10276 (Hastelloy C-276) Nickel Alloy Steel Pipes

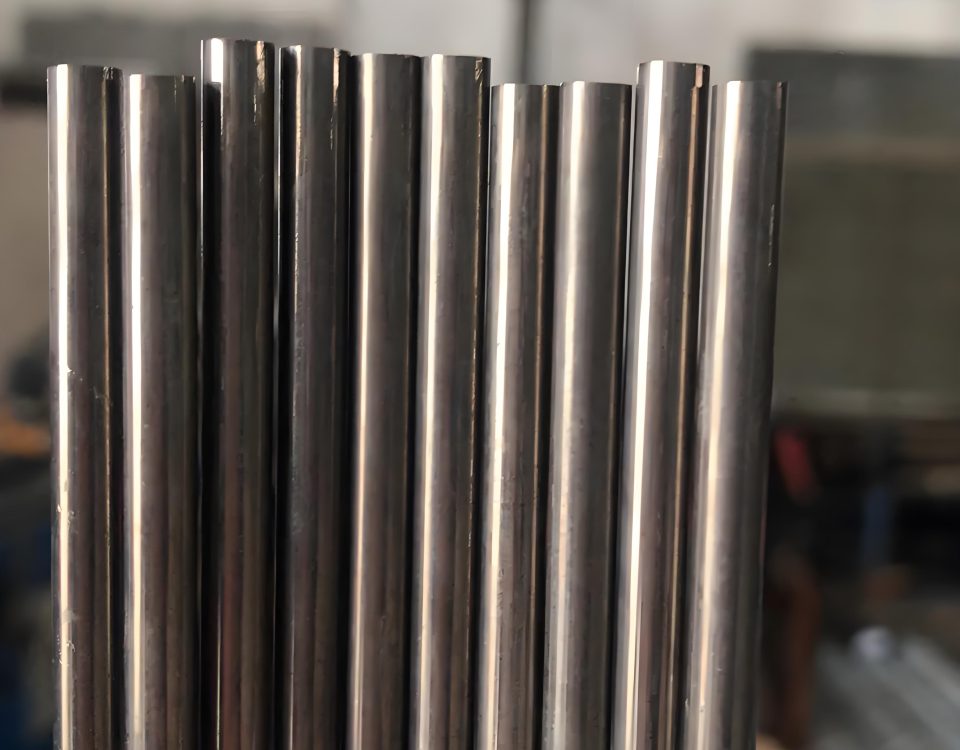

UNS N10276, commonly known as Hastelloy C-276, is a nickel-molybdenum-chromium alloy with excellent corrosion resistance in a wide range of severe environments. This alloy is known for its resilience to pitting, crevice corrosion, and stress corrosion cracking, making it ideal for challenging chemical processing and industrial applications.

Key Features

- Material: Hastelloy C-276 (UNS N10276)

- Corrosion Resistance: Exceptional resistance to pitting, stress corrosion cracking, and oxidizing atmospheres up to 1900°F (1038°C)

- Mechanical Properties: High strength and toughness

- Weldability: Excellent, with minimal carbide precipitation during welding, maintaining corrosion resistance in as-welded structures

Composition

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | Balance |

| Molybdenum (Mo) | 15.0 – 17.0 |

| Chromium (Cr) | 14.5 – 16.5 |

| Iron (Fe) | 4.0 – 7.0 |

| Tungsten (W) | 3.0 – 4.5 |

| Cobalt (Co) | 2.5 max |

| Manganese (Mn) | 1.0 max |

| Vanadium (V) | 0.35 max |

| Silicon (Si) | 0.08 max |

| Carbon (C) | 0.01 max |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.03 max |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength, min (psi) | 100,000 (690 MPa) |

| Yield Strength, min (psi) | 41,000 (283 MPa) |

| Elongation in 2 in. (50 mm), min (%) | 40% |

| Hardness (Rockwell B) | 85 max |

Manufacturing Specifications and Quality Assurance

Our UNS N10276 Hastelloy C-276 pipes are manufactured to meet stringent quality requirements, ensuring reliability in the most demanding environments.

Required Tests

- Chemical Analysis: Ensures the material meets specified chemical composition.

- Tensile Properties Testing: Verifies tensile strength, yield strength, and elongation.

- Hydrostatic or Nondestructive Electric Testing: Ensures the integrity and quality of each pipe.

- Hardness Testing: Confirms the material’s hardness range.

- Dimensional Inspection: Verifies compliance with specified dimensional tolerances.

Permissible Variations in Outside Diameter and Wall Thickness

Outside Diameter

| Outside Diameter (inches) | Permissible Variation (inches) |

|---|---|

| Up to and including 1/2″ | ± 0.004 |

| Over 1/2″ to 1-1/2″ | ± 0.006 |

| Over 1-1/2″ to 2-1/2″ | ± 0.010 |

| Over 2-1/2″ to 3-1/2″ | ± 0.016 |

| Over 3-1/2″ to 5″ | ± 0.020 |

Wall Thickness

| Wall Thickness (inches) | Permissible Variation |

|---|---|

| Up to 0.049 | ± 15% |

| 0.050 to 0.083 | ± 12.5% |

| Over 0.083 | ± 10% |

Application Areas

Given its robust properties, UNS N10276 Hastelloy C-276 is used in a variety of high-demand applications, including:

- Chemical Processing: Ideal for handling aggressive chemicals and high-temperature processes.

- Pollution Control: Used in flue gas desulfurization systems.

- Oil and Gas: Suitable for sour gas environments and offshore platforms.

- Power Generation: Components in gas turbines and other high-temperature applications.

- Pharmaceuticals: Manufacturing equipment requiring high levels of cleanliness and corrosion resistance.

- Pulp and Paper: Digesters and bleach plants.

Conclusion

Our UNS N10276 (Hastelloy C-276) nickel alloy steel pipes are designed to meet the highest standards of quality