ASTM A556 SEAMLESS STEEL BOILER PIPE

January 8, 2024

Induction Bending Pipe

January 14, 2024Enhancing pipeline integrity with mechanically lined pipes is a topic I am well-versed in as an engineer. Here is a comprehensive guide that covers material and size considerations, backing material, CRA (Corrosion-Resistant Alloy) liner material, technical features, mechanical properties, material selection, standard specifications, and tests and inspections.

- Material & Size:

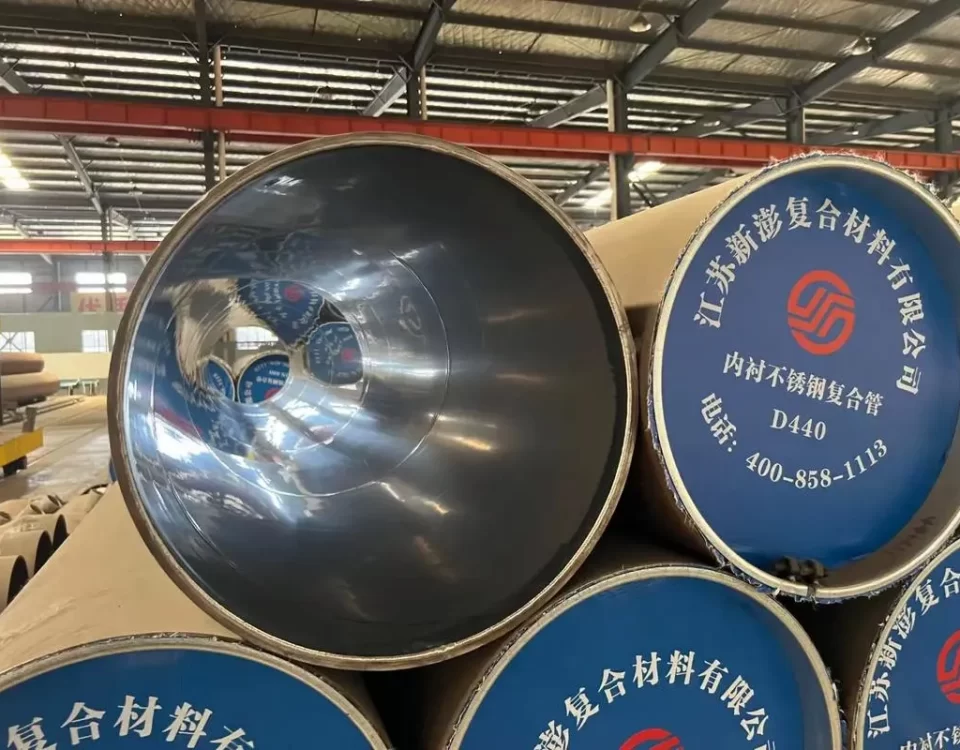

Mechanically lined pipes typically consist of an outer carrier pipe and an inner liner pipe. The carrier pipe is commonly made of carbon steel or low-alloy steel, while the liner pipe is composed of a corrosion-resistant alloy (CRA) material such as stainless steel, duplex stainless steel, or nickel alloys. The size range of mechanically lined pipes can vary, starting from small diameters up to larger dimensions, depending on the specific project requirements. - Backing Material:

The backing material, which is the outer carrier pipe, provides structural support and is responsible for withstanding external loads and pressures. The selection of the backing material depends on factors such as the operating conditions, design requirements, and project specifications. - CRA Liner Material:

The CRA liner material is selected based on its corrosion resistance properties to ensure protection against the transported fluids. Different CRA materials have varying levels of resistance to specific corrosive environments. The selection of the liner material depends on factors such as the fluid composition, temperature, pressure, and pH. - Technical Features of Mechanically Lined Pipes:

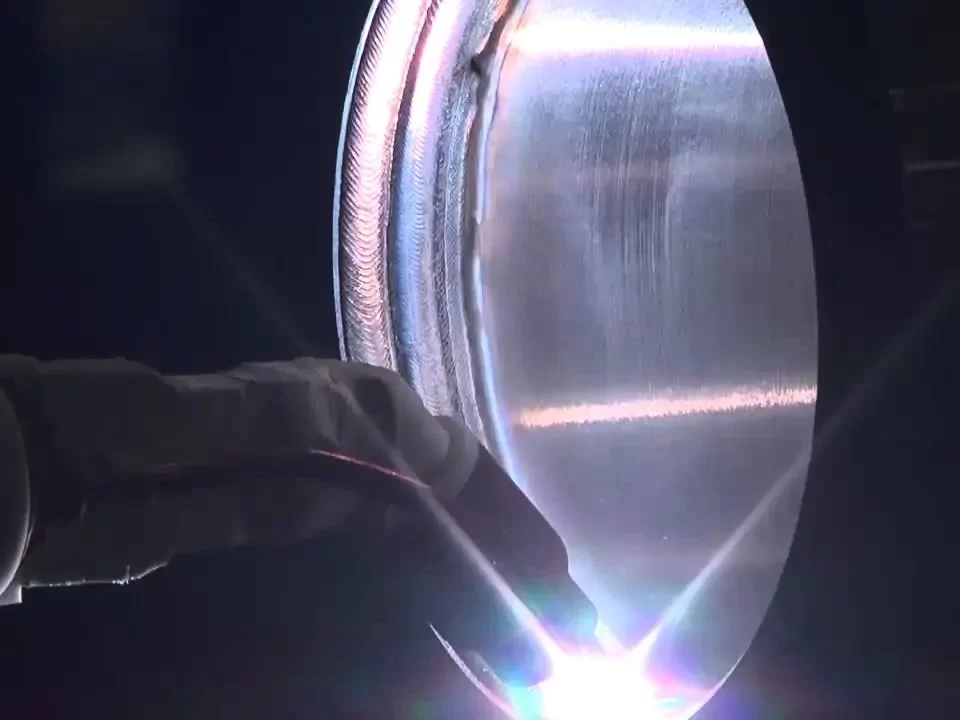

Mechanically lined pipes are designed to provide a tight and secure mechanical bond between the inner liner and the outer carrier pipe. This bond is achieved through precision engineering techniques, such as hydroforming or other mechanical interlocking mechanisms. The tight fit ensures a reliable connection that can withstand external stresses, vibrations, and thermal expansion. - Mechanical Properties:

Mechanically lined pipes must possess adequate mechanical properties to ensure structural integrity and withstand operational conditions. These properties include tensile strength, yield strength, elongation, impact resistance, and hardness. The mechanical properties are determined by the choice of materials and the manufacturing processes employed. - Material Selection and Standard Specification:

The selection of materials for mechanically lined pipes is crucial and depends on factors such as the conveyed fluid, operating temperature, pressure, and environmental conditions. Various international standards, including API (American Petroleum Institute), ASTM (American Society for Testing and Materials), DNV (Det Norske Veritas), and ISO (International Organization for Standardization), provide specifications and guidelines for material selection, fabrication, and testing. - Tests and Inspection:

Mechanically lined pipes undergo rigorous testing and inspection to ensure compliance with industry standards and project requirements. These tests include hydrostatic testing, dimensional inspection, visual inspection, non-destructive testing (such as ultrasonic testing or radiographic examination), and destructive testing (such as tensile testing or impact testing). These tests verify the integrity, mechanical properties, and corrosion resistance of the pipes.

In conclusion, enhancing pipeline integrity with mechanically lined pipes requires careful consideration of material selection, size, technical features, mechanical properties, adherence to standard specifications, and rigorous testing and inspection. By leveraging the advantages of mechanically lined pipes, such as corrosion resistance and mechanical strength, industries can achieve reliable and long-lasting pipeline systems.

Certainly! As an engineer, I understand the importance of data analysis in evaluating the performance and effectiveness of innovations such as mechanically lined pipes. Here is a sample data analysis table that can be used to assess the superiority of mechanically lined pipes in providing protection for fluid conveyance:

| Test Parameter | Measured Value | Acceptance Criteria | Result |

|---|---|---|---|

| Corrosion Resistance | No visible signs of corrosion after exposure to corrosive fluid for X hours | No visible signs of corrosion | Pass |

| Mechanical Bond Strength | Tensile strength of the mechanical bond between inner liner and outer carrier pipe | Minimum strength requirement of X MPa | Pass |

| Dimensional Accuracy | Inner diameter, outer diameter, and wall thickness | Within specified tolerances | Pass |

| Hydrostatic Testing | Pressure resistance of the pipe | No leaks or failures at X% above maximum operating pressure | Pass |

| Non-Destructive Testing | Ultrasonic testing or radiographic examination | No defects or discontinuities detected | Pass |

| Destructive Testing | Tensile strength, yield strength, and elongation | Meet or exceed specified mechanical properties | Pass |

| Visual Inspection | Surface condition, weld quality, and overall appearance | No visible defects or anomalies | Pass |

This data analysis table allows engineers and quality control personnel to record and evaluate the results of various tests performed on mechanically lined pipes. By comparing the measured values against the acceptance criteria, it becomes possible to determine whether the pipes meet the required standards and specifications.

Data analysis plays a crucial role in identifying any potential issues or weaknesses and ensuring the superiority of mechanically lined pipes in providing superior protection for fluid conveyance. It allows for informed decision-making, continuous improvement, and the assurance of reliable and efficient performance in industrial applications.