API 5L GRADE-B CARBON STEEL PIPE 40″,ANSI B16.25 for Kuwait

April 25, 2018

ERW weleded pipe for Water supply project in Ethiopia, API 5L grade X52 ERW

April 28, 2018Hi There,

Our company, CRD Transmark Ltd New Zealand, is a leading pipes, fittings and valves supplier at New Zealand.

We looking for the following pipes for a client locally. These pipes are to be used for Hot Water Boiler. Material Carbon Steel, A106 Grade B is ok

90 lengths x 76.1mm OD diameter X 3.2 mm wall thickness x 4740mm long,

51 lengths x 76.1mm OD diameter x 3.2 mm wall thickness x 5490 mm long.

If you can only offer 6 meter long standard length, we can accept 6 meter long pipes.

If you can offer FOB Auckland, New Zealand price that will be great. If not, please offer FOB Tianjing price.

Let us know the weight and dimension (length x width x height)

I am looking forward to your reply.

ASTM Carbon Steel Pipe A106 Grade B for Hotwater Boiler Dimensions Schedule

The standard covers pipe sizes in NPS (National Standard Straight) from 1/8 inch to 48 inch (10.3mm DN6 – 1219mm DN1200), meanwhile complied the nominal wall thickness of the standard ASME B 36.10M. For other sizes out of the ASME B 36.10M is also allowed to use this standard specification.

Raw materials

The materials used for ASTM A106 standard specification shall be applicable for bending, flanging, or the similar forming processes. In case the steel material is to be welded, the welding process supposed to be suitable for this grade of ASTM A106, and applicable for the high temperature working environment.

Where there is a superior or a higher grade for the ASTM A106 steel pipe is required, the standard has a optional specification for the supplementary requirements, for the pipes that used this standard. More over, these supplementary specification asked for the additional test, when the order is to be placed.

Standards referred for making Carbon Steel Pipe A106 Grade B Boiler Pipe Dimensions Schedule

References ASTM standards:

a. ASTM A530/ A530M This is the standard specification for the common requirements of the carbon, and alloy pipes.

b. E213 The standard for the Ultrasonic Examination test

c. E309 The standard for the Eddy Current examination test

d. E381 The standard for the plan of Macroetch test, for the steel products the steel bars, steel billets, blooms, and forging steels.

e. E570 The standard for the test plan for the flux leakage test of the ferromagnetic steel pipe and pipeline products.

f. Related ASME Standard:

g. ASME B 36.10M The nominal sizes standard specification for the welded and seamless steel pipe.

h. Related Military standard:

i. MIL-STD-129 The standard for the markings of shipment and storage.

j. MIL-STD-163 The standard for the storage and shipment for the steel forging products.

k. Related federal standard:

l. Fed. Std. No. 123 The standard for the civil agencies for the marking and shipments.

m. Fed. Std. No. 183 The standard specification for the continuous ID marking for steel products

n. Surface standard:

o. SSPC-SP 6 The standard specification for the surface.

A106 gr.B Hotwater Boiler

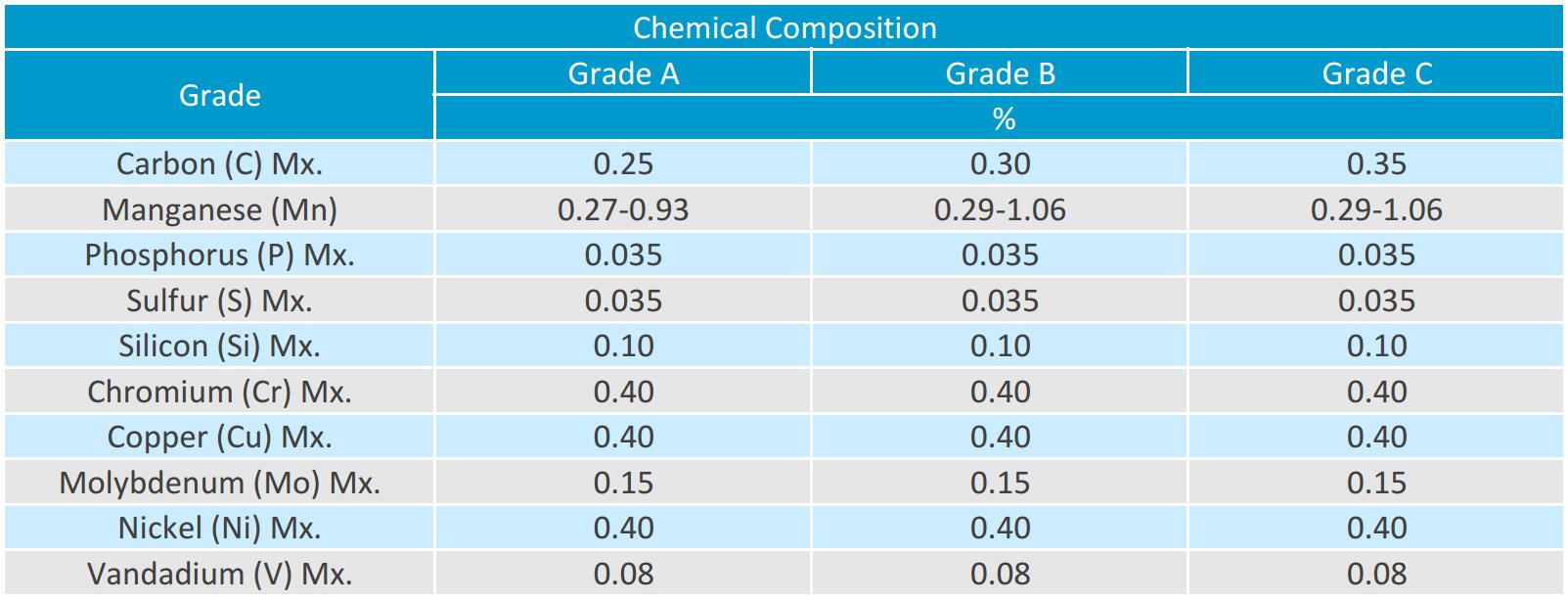

ASTM A106 standard specifications for the seamless steel pipe have three grades, that is ASTM A106 Gr. A, Grade. B and C, with the higher grade material, the strength performance is better.

Test Methods

The test methods for the ASTM A106 A, B, C are the flattening tests, hydrostatic test, nondestructive electric test, Ultrasonic test, eddy current test, flux leakage test, these test procedures shall be notified or discussed with client to confirm what kind of test will be applied.

Chemical composition and Mechanical Strength

ASTM A106 GR.B and A pipe chemical composition

Please note:

For each reduction of 0.01% for maximum carbon element, an increase of 0.06% manganese above the specified value shall be permitted, and up to maximum of 1.35%.

Elements Cr, Cu, Mo, Ni, V combined shall not exceed 1%.

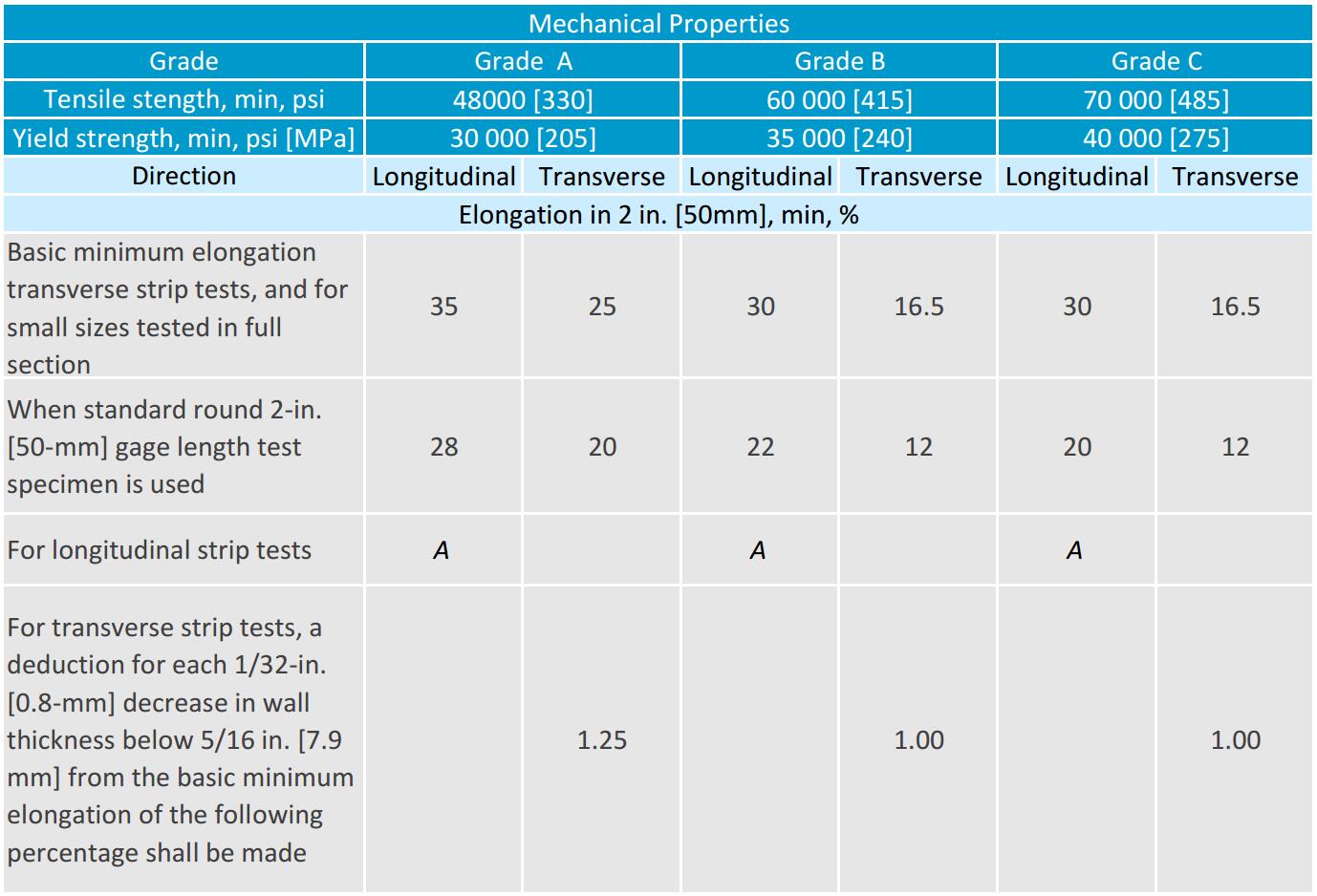

ASTM A106 gr.B Tensile Strength and Yield Strength

Elongation formula:

In 2 in. [50mm], shall be calculated by: e = 625 000 A^0.2 / U^0.9

For inch-pound Units, e = 1940 A^0.2 / U^0.9

Explanations of e, A, and U, please find here. (Equation same with ASTM A53, API 5L pipe.)

Tensile Strength, min, psi [MPa] Grade A 48,000 [330], Grade B 60,000 [415], Grade C 70,000 [485]

Yield Strength minimum at psi [MPa] Grade A 30,000 [205], B 35,000 [240], C 40,000 [275]

Elongation in 2 in (50mm), minimum percentage % ,

For all small sizes tested in full section, basic minimum elongation transverse trip tests: Grade A Longitudinal 35, Transverse 25; B 30, 16.5; C 30, 16.5;

In case standard round 2 inch gage length test sample is used, above values are: Grade A 28, 20; B 22, 12; C 20, 12.

Regards,

Ivy Tan

CRD Transmark Ltd (New Zealand)

Sales Engineer