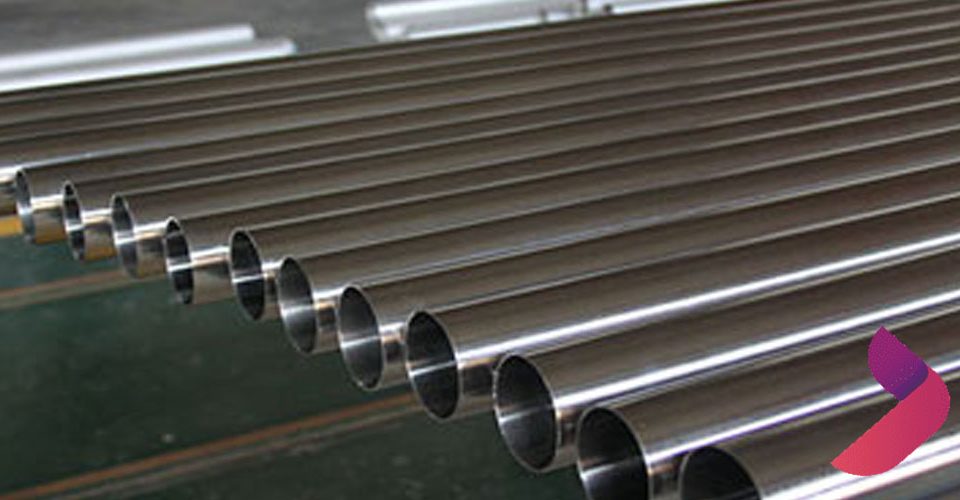

Incoloy 800 Alloy Seamless steel Pipe

December 21, 2023

FBE Coated Pipe – The Water transporting Guardian

December 28, 2023Understanding the Mechanical Behavior and Characteristics of Incoloy 800 Alloy Seamless Pipes

Introduction

Incoloy 800 alloy seamless pipes are renowned for their exceptional mechanical properties and high resistance to corrosion. In this article, we will delve into the mechanical behavior, chemical elements, equivalent materials, standard specifications, characteristics, wall thickness, and pressure ratings of Incoloy 800 alloy seamless pipes.

The chemical elements present in Incoloy 800 alloy seamless pipe contribute to its unique properties. The composition typically includes:

- Nickel (Ni): Provides excellent corrosion resistance and enhances the overall strength of the alloy.

- Chromium (Cr): Contributes to the alloy’s resistance against oxidation and corrosion.

- Iron (Fe): Acts as a base element and provides a solid foundation for the alloy’s mechanical properties.

- Carbon (C): Enhances the high-temperature strength of the alloy.

- Aluminum (Al): Facilitates the formation of a protective oxide layer, improving resistance to high-temperature environments.

1. Mechanical Behavior of Incoloy 800 Alloy Seamless Pipe

Incoloy 800 alloy seamless pipes exhibit excellent mechanical properties, making them suitable for various applications. Some key mechanical characteristics of these pipes include:

- Tensile Strength: Incoloy 800 alloy seamless pipes have a high tensile strength, typically ranging from 500 to 700 MPa. This strength allows them to withstand significant loads and pressures.

- Yield Strength: The yield strength of Incoloy 800 alloy seamless pipes is approximately 200 to 300 MPa. This property indicates the stress level at which the material begins to deform permanently.

- Elongation: Incoloy 800 alloy seamless pipes have a notable elongation percentage, typically around 30%. This indicates the ability of the material to stretch before fracture, making it suitable for applications where flexibility is required.

- Hardness: Incoloy 800 alloy seamless pipes have a hardness value of approximately 150 to 200 HB. This moderate hardness ensures good formability and machinability while maintaining structural integrity.

2. Chemical Elements of Incoloy 800 Alloy Seamless Pipe

The chemical composition of Incoloy 800 alloy seamless pipes plays a vital role in their exceptional corrosion resistance and mechanical properties. The primary chemical elements present in these pipes include:

- Nickel (Ni): Nickel is the primary element in Incoloy 800 alloy seamless pipes, constituting around 30-35% of the composition. Nickel enhances the pipes’ resistance to corrosion, high-temperature strength, and thermal stability.

- Chromium (Cr): Chromium is another essential element in Incoloy 800 alloy seamless pipes, comprising approximately 19-23% of the composition. Chromium forms a protective oxide layer on the surface, providing excellent resistance to oxidation and corrosion.

- Iron (Fe): Iron is the base element in Incoloy 800 alloy seamless pipes, constituting the majority of the composition. It provides structural integrity and excellent mechanical properties to the pipes.

3. Equivalent Material of Inconel 800 Alloy Seamless Pipe

Inconel 800 alloy seamless pipes have an equivalent material known as Incoloy 800H. Incoloy 800H offers similar mechanical properties and chemical composition as Inconel 800, making it a suitable alternative in various applications.

4. Inconel 800Ht Alloy Seamless Pipe Standard Specification

Inconel 800Ht alloy seamless pipes adhere to specific standard specifications to ensure their quality and compatibility. The standard specifications for Inconel 800Ht alloy seamless pipes include:

- ASTM B407: This specification covers nickel-iron-chromium alloy seamless pipes suitable for high-temperature applications.

- ASTM B163: This specification covers seamless nickel and nickel alloy condenser and heat-exchanger tubes.

5. Characteristics of Incoloy 800 Alloy Seamless Pipe

Excellent resistance to oxidation and carburization in high-temperature environments.

Superior corrosion resistance to various acids, alkalis, and chloride solutions.

High strength and toughness, allowing the pipe to withstand high-pressure and high-stress conditions.

Good workability, making it easy to fabricate and install.

Excellent dimensional accuracy, ensuring compatibility with fittings and connectors.

Longevity and reliability, even in demanding industrial applications.

Incoloy 800 alloy seamless pipes possess several notable characteristics, contributing to their widespread usage in various industries. These characteristics include:

- High Corrosion Resistance: Incoloy 800 alloy seamless pipes exhibit excellent resistance to corrosion in various environments, including aqueous and high-temperature conditions.

- Good Thermal Stability: These pipes can withstand high temperatures and maintain their mechanical properties, making them ideal for applications involving heat transfer.

- Excellent Weldability: Incoloy 800 alloy seamless pipes have good weldability, allowing for easy fabrication and installation.

- Low Thermal Expansion: These pipes have a low coefficient of thermal expansion, minimizing the risk of deformation and stress during temperature fluctuations.

6. Wall Thickness of Incoloy 800 Alloy Seamless Pipe

The wall thickness of Incoloy 800 alloy seamless pipes varies based on the specific application requirements. The pipes are available in various schedules, such as SCH 10, SCH 40, SCH 80, and others, with different wall thicknesses to accommodate different pressure and temperature conditions.

7. Pressure Rating of Incoloy Alloy 800 Tube

The pressure rating of Incoloy 800 alloy seamless pipes depends on factors such as wall thickness, temperature, and pipe dimensions. These pipes have high-pressure ratings, typically ranging from 1500 to 2000 psi, making them suitable for demanding applications.

Conclusion

Incoloy 800 alloy seamless pipes exhibit exceptional mechanical behavior, high corrosion resistance, and desirable characteristics, making them a preferred choice for various industries. Understanding the mechanical properties, chemical elements, equivalent materials, standard specifications, characteristics, wall thickness, and pressure ratings of these pipes is crucial for selecting the appropriateConclusion

Incoloy 800 alloy seamless pipes exhibit exceptional mechanical behavior, high corrosion resistance, and desirable characteristics, making them a preferred choice for various industries. Understanding the mechanical properties, chemical elements, equivalent materials, standard specifications, characteristics, wall thickness, and pressure ratings of these pipes is crucial for selecting the appropriate piping solution for specific applications.

These pipes offer excellent tensile and yield strength, notable elongation, and moderate hardness. The nickel, chromium, and iron composition provides high corrosion resistance, thermal stability, and structural integrity. Incoloy 800 alloy seamless pipes can withstand high temperatures, making them suitable for applications involving heat transfer. Their good weldability and low thermal expansion add to their versatility.

Incoloy 800 alloy seamless pipes are available in various schedules and sizes to accommodate different requirements. The wall thickness varies based on the application, and the pressure ratings of these pipes are high, making them suitable for demanding environments.

Overall, Incoloy 800 alloy seamless pipes provide a reliable and durable solution for industries requiring corrosion resistance, strength, and thermal stability. Their outstanding mechanical properties and chemical composition make them a go-to choice for applications in petrochemical, power generation, aerospace, and other industries where high-performance piping is essential.