PERFORMANCE OF Nb/Cu CLAD SEAMLESS SC CAVITY MADE FROM A PIPE BY HOT&COLD ROLLING AND DEEP-DRAWING

June 29, 2022

Effect of Groove Designs on Residual Stress and Transverse Shrinkage in GMAW and PGMAW of A333 Seamless Steel Pipes

June 29, 2022The influence of the processing parameters on the performance of the two-roll piercing operation

Article in Journal of Mechanical Working Technology · September 1987

Abstract

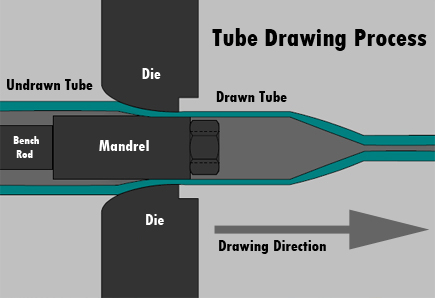

Over the past decade, the demand for higher quality oil-country tubular goods has been increasing and to meet this demand, seamless-pipe mills have been active in developing new and improved hot-mill practices. For a hot-rolled tube on the cooling table, higher quality means more precise dimensions and improved surface quality. It is reported that pass design, piercer set-up and operating parameters have substantial influence on both dimensional and surface quality. Experimental work was conducted to determine the influence of pass/set-up design and operating parameters on the performance of first-piercing mill operation. Results showed that control of these parameters leads to an optimum pass-design that produces conditions favorable not only for enhanced deformation before fracture but also for increasing the efficiency of the mill. In this experimental work the aim was to describe the basic relationships between processing variables and their influence on the piercing performance, whilst at the same time the determination of the best overall set-up design was proposed.

The influence of the processing parameters on the performance of the two-roll piercing operation

-steel-pipe.jpg)