Load-Carrying Capacity of Steel Pipe Piles

November 30, 2024

Carbon Steel Hollow Section: Square, Rectangular, and Circular

December 11, 2024Outline: Benefits of Epoxy Pipe Liners for Corrosion Protection

| Heading | Subheading |

|---|---|

| H1: Introduction to Epoxy Pipe Liners | |

| H2: What are Epoxy Pipe Liners? | Definition and Composition |

| H2: Understanding Pipe Corrosion | Causes of Pipe Corrosion |

| H3: The Science of Corrosion in Pipes | Chemical Processes Behind Corrosion |

| H3: How Corrosion Impacts Pipe Infrastructure | Consequences for Water Systems and Industry |

| H2: How Epoxy Pipe Liners Work | Mechanism of Epoxy Application |

| H3: Types of Epoxy Liner Coatings | Different Variants Available |

| H3: The Application Process | How Epoxy is Applied to Pipes |

| H2: Advantages of Epoxy Pipe Liners | Key Benefits for Corrosion Protection |

| H3: Longevity and Durability | How Epoxy Enhances Pipe Lifespan |

| H3: Cost-Effectiveness | Economic Benefits of Epoxy Lining |

| H3: Minimal Disruption to Operations | Non-invasive Process for Pipe Repair |

| H3: Reduced Maintenance and Repair Costs | Long-Term Savings |

| H3: Environmental Benefits | Eco-Friendly Aspects of Epoxy Liners |

| H2: Applications of Epoxy Pipe Liners | Common Industries Using Epoxy Coatings |

| H3: Water and Wastewater Treatment Plants | Epoxy as a Solution for Municipal Pipes |

| H3: Industrial Pipelines | Use in Manufacturing and Chemical Plants |

| H3: Residential Plumbing | Applications in Home Plumbing Systems |

| H2: Challenges and Considerations in Epoxy Lining | Limitations and Risks of Epoxy Coatings |

| H3: Compatibility Issues | When Epoxy Might Not Be Suitable |

| H3: Installation Time and Costs | Time-Related Factors in Epoxy Application |

| H2: Case Studies and Success Stories | Real-World Examples of Epoxy Liner Benefits |

| H2: Future Trends in Corrosion Protection | Innovations in Epoxy Technology and Use |

| H2: Conclusion | Final Thoughts on Epoxy Pipe Liners for Corrosion Protection |

| H2: Frequently Asked Questions (FAQs) |

H1: Introduction to Epoxy Pipe Liners

Corrosion in pipes is a long-standing problem for both residential and industrial systems. Over time, various external and internal factors degrade metal pipes, leading to leaks, blockages, and inefficiencies. Epoxy pipe liners have emerged as a revolutionary solution to tackle this issue. These liners provide a protective coating that enhances the structural integrity of pipes and extends their lifespan. In this article, we’ll explore the benefits of epoxy pipe liners for corrosion protection, how they work, and why they are considered a game-changer for pipe maintenance.

H2: What are Epoxy Pipe Liners?

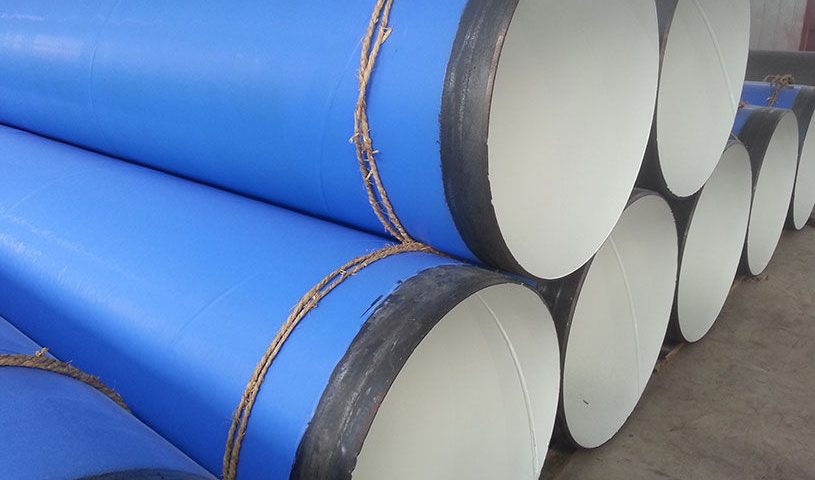

Epoxy pipe liners are a type of resin-based coating applied to the interior of pipes to provide corrosion protection. This material forms a strong, durable barrier between the pipe material and the corrosive elements (water, chemicals, or air) inside the pipe. Composed of epoxy resins, these liners bond tightly to the inner surface of pipes, providing a waterproof, chemically resistant layer. The epoxy material is often mixed with hardeners and fillers, creating a highly durable finish that resists abrasion and degradation.

Definition and Composition

An epoxy pipe liner is typically made of two components: an epoxy resin and a hardener. When these components are mixed, they create a chemical reaction that results in a solid, durable coating once applied to the pipes. This liner acts as a protective shield, preventing corrosion from environmental factors like moisture, chemicals, and fluctuating temperatures.

H2: Understanding Pipe Corrosion

Corrosion is a natural process in which metal gradually deteriorates due to chemical reactions with substances like oxygen and water. In pipes, corrosion can cause significant damage, including leaks, decreased water quality, and even structural failure. Understanding what causes pipe corrosion is essential to appreciating how epoxy liners help prevent it.

Causes of Pipe Corrosion

The most common causes of corrosion in pipes are:

- Chemical Reactions: Water can be highly acidic or alkaline, which can accelerate corrosion in metal pipes.

- Oxygen Exposure: The presence of oxygen in the pipe can lead to oxidation, weakening the pipe structure.

- Electrochemical Corrosion: When pipes are exposed to different metals or electrical currents, it can cause galvanic corrosion, where one metal corrodes faster than the other.

- Microbial Activity: Certain bacteria can accelerate corrosion in pipes, especially in water systems.

The Science of Corrosion in Pipes

Corrosion is a complex electrochemical process. When metal is exposed to water or air, the metal atoms lose electrons and form metal ions. These ions dissolve into the water, leading to rust or other forms of degradation. Over time, this corrosion can thin the pipe walls and create holes, making the system susceptible to leaks.

How Corrosion Impacts Pipe Infrastructure

Pipe corrosion is not only costly in terms of repair but can also result in reduced water flow, decreased system efficiency, and potentially hazardous material contamination. Leaking pipes can cause water wastage, further damaging the surrounding environment and property.

H2: How Epoxy Pipe Liners Work

Epoxy pipe liners work by creating a chemical barrier between the pipe material and the corrosive elements. When applied correctly, they seal the interior of the pipe, preventing water, chemicals, and oxygen from coming into contact with the pipe surface.

Mechanism of Epoxy Application

The process of applying an epoxy pipe liner typically involves cleaning the interior of the pipe to remove debris, rust, and other impurities. Once the pipe is prepped, the epoxy resin is applied either by spraying, pouring, or pulling the liner into place. The resin then hardens, forming a durable, seamless coating that prevents further corrosion.

Types of Epoxy Liner Coatings

- Spray-on Epoxy Liners: Applied directly onto the pipe using a spray application for quick repairs.

- Cured-in-Place Liners (CIPP): A flexible liner is inserted into the pipe and cured using heat or UV light, providing a seamless, durable lining.

- Epoxy Coating Kits: These are DIY solutions for smaller pipe sections, often used in residential plumbing.

The Application Process

The application of epoxy liners is typically performed in several stages:

- Preparation: The pipe is cleaned thoroughly, and any damage is assessed.

- Liner Insertion: The epoxy material is applied to the pipe’s interior, ensuring full coverage.

- Curing: The liner is left to cure, which can take anywhere from a few hours to a day, depending on the method used.

H2: Advantages of Epoxy Pipe Liners

Epoxy pipe liners offer several compelling advantages that make them an attractive option for corrosion protection.

Longevity and Durability

One of the key benefits of epoxy pipe liners is their long-lasting nature. Once applied, epoxy coatings can protect pipes for decades, significantly extending the lifespan of plumbing systems. Unlike traditional materials, epoxy is resistant to chemicals, water, and extreme temperatures, making it an ideal solution for long-term protection.

Cost-Effectiveness

Epoxy pipe liners are often more affordable than completely replacing corroded pipes. The application process is faster and requires less labor, translating to lower overall costs. Additionally, because epoxy liners prevent future corrosion, they reduce the need for frequent repairs and replacements.

Minimal Disruption to Operations

Unlike traditional pipe replacement methods, which may involve digging and major disruption to property or business operations, epoxy pipe lining is minimally invasive. It can be applied without major excavation, reducing downtime and the inconvenience of repairs.

Reduced Maintenance and Repair Costs

By protecting pipes from corrosion, epoxy liners reduce the need for frequent repairs. This can save significant amounts of money on pipe replacement, especially in industrial and municipal systems where pipes are large and complex.

Environmental Benefits

Epoxy pipe liners are environmentally friendly. They help reduce waste associated with replacing entire pipe systems, and many modern epoxy materials are designed to be non-toxic and safe for drinking water.

H2: Applications of Epoxy Pipe Liners

Epoxy pipe liners are versatile and can be used in a variety of industries and applications, including:

Water and Wastewater Treatment Plants

In municipal water and wastewater systems, epoxy pipe liners prevent corrosion in pipes that carry potable water or wastewater, ensuring cleaner water quality and reducing maintenance costs.

Industrial Pipelines

In industries like manufacturing, chemical processing, and oil refining, epoxy coatings protect pipelines from corrosive substances, extending the life of infrastructure and reducing the risk of downtime due to pipe failures.

Residential Plumbing

Homeowners also benefit from epoxy lining, especially when dealing with older plumbing systems. Epoxy liners provide a cost-effective way to extend the lifespan of pipes without the need for invasive pipe replacement.

H2: Challenges and Considerations in Epoxy Lining

While epoxy pipe liners offer numerous benefits, there are also challenges and considerations to keep in mind.

Compatibility Issues

Epoxy liners may not be compatible with all types of pipe materials. For example, some older pipes may have physical conditions that prevent proper bonding with the epoxy resin.

Installation Time and Costs

While generally cost-effective, the installation of epoxy liners can take time, especially for larger systems or complex pipes. It may also require specialized equipment, which can add to the overall cost.

H2: Case Studies and Success Stories

Numerous municipalities and industries have successfully used epoxy pipe liners to extend the life of their piping systems. For instance, a major city in the U.S. used epoxy lining to repair its aging water distribution pipes, saving millions of dollars in replacement costs and reducing water loss by 20%.

H2: Future Trends in Corrosion Protection

As technology advances, epoxy pipe linings continue to improve. Innovations in materials, installation techniques, and coatings are making epoxy even more effective at preventing corrosion and extending the lifespan of pipes.

H2: Conclusion

Epoxy pipe liners offer a cost-effective, durable, and environmentally friendly solution for corrosion protection in pipes. Whether for residential plumbing, industrial pipelines, or municipal water systems, epoxy liners can significantly extend the life of infrastructure and reduce maintenance costs. As this technology continues to evolve, the future of corrosion protection looks promising.

H2: Frequently Asked Questions (FAQs)

Q1: How long do epoxy pipe liners last?

Epoxy pipe liners can last between 50 to 100 years, depending on the quality of the materials used and the environmental conditions.

Q2: Are epoxy pipe liners safe for drinking water?

Yes, many modern epoxy liners are certified as safe for drinking water and are NSF/ANSI 61 compliant.

Q3: Can epoxy liners be applied to any type of pipe?

While epoxy liners are compatible with most materials, they may not be suitable for certain types of old or deteriorating pipes. A professional inspection is recommended.

Q4: How long does it take to install an epoxy pipe liner?

The installation process can take anywhere from a few hours to several days, depending on the size of the pipes and the method used.

Q5: Is the epoxy pipe lining process disruptive?

No, the process is minimally invasive and typically does not require excavation or significant disruption to property or business operations.

Q6: How much does epoxy pipe lining cost?

The cost varies based on the size and condition of the pipes. However, it is often more affordable than traditional pipe replacement methods.