3PE Coated Pipe Installation and Construction – Customer Case Study

August 3, 2024

The Future of Seamless Pipe Technology: Trends and Predictions

August 16, 2024HDPE Inner Steel Pipe System for Drinking Water Pipelines

Introduction

In the quest for reliable and safe drinking water distribution, the choice of pipeline materials is paramount. One innovative solution that has gained traction in recent years is the HDPE inner steel pipe system. This hybrid system combines the strength and durability of steel with the corrosion resistance and flexibility of High-Density Polyethylene (HDPE). This article provides an in-depth analysis of the HDPE inner steel pipe system, exploring its design, benefits, applications, and technical specifications.

The Evolution of Drinking Water Pipelines

Traditional Materials

Historically, drinking water pipelines have been constructed from materials such as cast iron, ductile iron, and concrete. While these materials have served their purpose, they come with limitations, including susceptibility to corrosion, heavy weight, and difficulty in installation.

Modern Solutions

Modern pipeline solutions have evolved to address these limitations. The HDPE inner steel pipe system represents a significant advancement, offering a combination of strength, flexibility, and corrosion resistance that traditional materials cannot match.

Design and Structure of HDPE Inner Steel Pipe System

HDPE Lining

The inner lining of the pipe is made from High-Density Polyethylene (HDPE), a thermoplastic known for its excellent chemical resistance, flexibility, and durability.

- Properties of HDPE:

- Chemical Resistance: HDPE is resistant to a wide range of chemicals, making it ideal for drinking water applications.

- Flexibility: HDPE can withstand ground movements and temperature fluctuations without cracking or breaking.

- Durability: HDPE has a long service life, often exceeding 50 years.

Steel Outer Layer

The outer layer of the pipe is constructed from steel, providing the necessary strength and structural integrity to withstand high pressures and external loads.

- Properties of Steel:

- Strength: Steel provides the mechanical strength required to handle high-pressure water distribution.

- Durability: Steel is known for its long-lasting performance and ability to withstand external impacts.

Bonding Process

The HDPE inner lining and the steel outer layer are bonded together using advanced manufacturing techniques, ensuring a strong and reliable connection between the two materials.

- Bonding Techniques:

- Extrusion Lining: HDPE is extruded onto the inner surface of the steel pipe, creating a seamless bond.

- Thermal Fusion: Heat is applied to fuse the HDPE lining to the steel, ensuring a tight and durable connection.

Benefits of HDPE Inner Steel Pipe System

Corrosion Resistance

One of the primary advantages of the HDPE inner steel pipe system is its excellent corrosion resistance. The HDPE lining protects the steel from corrosive elements, ensuring a long service life and reducing maintenance costs.

Strength and Durability

The steel outer layer provides the necessary strength to withstand high pressures and external loads, making the system suitable for a wide range of applications, including high-pressure water distribution.

Flexibility

The flexibility of the HDPE lining allows the pipe to accommodate ground movements and temperature fluctuations, reducing the risk of leaks and breaks.

Cost-Effectiveness

While the initial cost of the HDPE inner steel pipe system may be higher than traditional materials, the long service life and reduced maintenance costs make it a cost-effective solution in the long run.

Safety and Hygiene

HDPE is a non-toxic material that does not leach harmful chemicals into the water, ensuring the safety and hygiene of drinking water.

Applications of HDPE Inner Steel Pipe System

Municipal Water Distribution

The HDPE inner steel pipe system is widely used in municipal water distribution networks, providing a reliable and durable solution for delivering safe drinking water to communities.

Industrial Applications

In industrial settings, the system is used to transport potable water for various processes, ensuring a consistent and safe water supply.

Rural and Remote Areas

The flexibility and durability of the HDPE inner steel pipe system make it ideal for use in rural and remote areas, where ground movements and harsh environmental conditions are common.

High-Pressure Applications

The strength of the steel outer layer makes the system suitable for high-pressure applications, such as water mains and transmission lines.

Technical Specifications

Pipe Sizes

The HDPE inner steel pipe system is available in a range of sizes to meet different application requirements.

- Common Sizes:

- Diameter: Ranges from 50mm to 1200mm.

- Length: Standard lengths are typically 6 meters or 12 meters, but custom lengths can be manufactured.

Pressure Ratings

The system is designed to handle various pressure ratings, depending on the application.

- Common Pressure Ratings:

- PN10: Suitable for low to medium pressure applications.

- PN16: Suitable for medium to high pressure applications.

- PN25: Suitable for high-pressure applications.

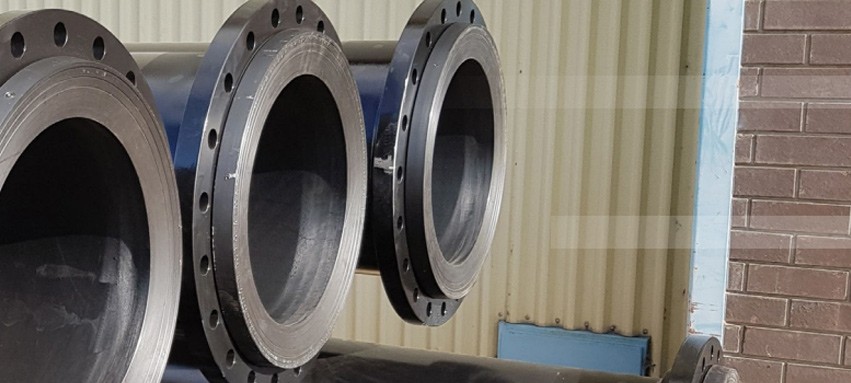

Connection Methods

The HDPE inner steel pipe system can be connected using various methods, ensuring a secure and leak-free connection.

- Common Connection Methods:

- Flanged Connections: Flanges are welded to the ends of the pipes, allowing for easy connection and disconnection.

- Butt Fusion: The HDPE lining is fused together using heat, creating a seamless and leak-free joint.

- Electrofusion: Special fittings with built-in heating elements are used to fuse the HDPE lining, ensuring a strong and reliable connection.

Conclusion

The HDPE inner steel pipe system represents a significant advancement in drinking water pipeline technology. By combining the strength and durability of steel with the corrosion resistance and flexibility of HDPE, this hybrid system offers a reliable and cost-effective solution for a wide range of applications. Whether used in municipal water distribution, industrial settings, or rural areas, the HDPE inner steel pipe system ensures the safe and efficient delivery of drinking water.

FAQ

1. What are the main advantages of the HDPE inner steel pipe system?

The main advantages include excellent corrosion resistance, strength and durability, flexibility, cost-effectiveness, and safety and hygiene for drinking water.

2. What materials are used in the HDPE inner steel pipe system?

The system combines an inner lining of High-Density Polyethylene (HDPE) with an outer layer of steel, bonded together using advanced manufacturing techniques.

3. What applications are suitable for the HDPE inner steel pipe system?

The system is suitable for municipal water distribution, industrial applications, rural and remote areas, and high-pressure applications.

4. How is the HDPE inner steel pipe system connected?

Common connection methods include flanged connections, butt fusion, and electrofusion, ensuring secure and leak-free joints.

5. What are the common sizes and pressure ratings for the HDPE inner steel pipe system?

Common sizes range from 50mm to 1200mm in diameter, with pressure ratings of PN10, PN16, and PN25, depending on the application.