Steel Water Pipe Design, Lining, Coating, Joints, and Installation

October 10, 2024-steel-pipe-150x150.jpg)

ASTM A335 P91 10Cr9Mo1VNbN Alloy Steel Pipe – Research on Welding and Heat Treatment Process

October 15, 2024Introduction: Overview of New Energy Steel Pipes

Steel pipes have long been a staple in various industries due to their strength, durability, and versatility. In the realm of new energy, these attributes are especially valuable as the world shifts towards more sustainable and efficient energy sources. Steel pipes are used extensively in applications such as wind farms, solar energy systems, and geothermal installations, where they play critical roles in transporting fluids, supporting structures, and ensuring the efficient operation of energy systems.

Application Status: Current Uses of New Energy Steel Pipes

In the new energy sector, steel pipes are utilized in a variety of ways:

- Wind Energy: Steel pipes are used in the construction of wind turbine towers, providing the necessary structural support to withstand harsh environmental conditions.

- Solar Energy: In solar thermal power plants, steel pipes transport heat-transfer fluids, facilitating the conversion of solar energy into electricity.

- Geothermal Energy: Steel pipes are essential for drilling and maintaining geothermal wells, allowing the extraction of heat from the earth’s core.

- Hydrogen Production: Steel pipes are used in the transportation and storage of hydrogen, a clean energy carrier with significant potential.

Demand Analysis: Factors Driving Demand for Steel Pipes

Several factors are driving the increasing demand for steel pipes in the new energy sector:

- Infrastructure Expansion: The growth of renewable energy projects requires extensive infrastructure, including pipelines and structural supports.

- Technological Advancements: Innovations in steel pipe manufacturing and design enhance their performance and applicability in new energy systems.

- Environmental Regulations: Stricter environmental standards necessitate the use of durable and sustainable materials, such as steel, in energy projects.

Potential Considerations: Key Factors to Consider when Using Steel Pipes

When integrating steel pipes into new energy systems, several considerations must be taken into account:

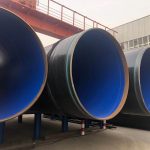

- Corrosion Resistance: Selecting appropriate coatings and linings to protect against corrosion and extend the lifespan of the pipes.

- Material Compatibility: Ensuring the steel is compatible with the fluids and gases it will transport, preventing chemical reactions and degradation.

- Structural Integrity: Designing pipes to withstand the pressures and environmental conditions they will encounter.

Environmental Impact: Sustainability of New Energy Steel Pipes

Steel pipes contribute to the sustainability of new energy systems in several ways:

- Recyclability: Steel is highly recyclable, reducing waste and conserving resources.

- Durability: The long lifespan of steel pipes minimizes the need for frequent replacements, reducing environmental impact.

- Energy Efficiency: Steel pipes facilitate efficient energy transfer, reducing losses and improving overall system performance.

Technological Advancements: Innovations Enhancing Steel Pipe Efficiency

Recent technological advancements have significantly enhanced the efficiency and performance of steel pipes:

- Advanced Coatings: New coating technologies improve corrosion resistance and reduce friction, enhancing flow efficiency.

- Smart Monitoring Systems: Integrated sensors and monitoring systems provide real-time data on pipe conditions, enabling proactive maintenance.

- Lightweight Alloys: The development of lightweight steel alloys reduces material costs and simplifies installation processes.

Cost Analysis: Economic Evaluation of Steel Pipes

The economic evaluation of steel pipes involves several factors:

- Initial Costs: The cost of materials, manufacturing, and installation.

- Maintenance Costs: The expenses associated with regular inspections, repairs, and replacements.

- Lifecycle Costs: The total cost of ownership over the pipe’s lifespan, including energy savings and reduced downtime.

Maintenance and Durability: Longevity and Maintenance Requirements

Steel pipes are known for their durability, but regular maintenance is essential to ensure their longevity:

- Inspection Schedules: Routine inspections help identify and address potential issues before they lead to failures.

- Repair Techniques: Advanced repair methods, such as welding and coating reapplication, extend the life of steel pipes.

- Environmental Considerations: Maintenance practices must comply with environmental regulations to minimize impact.

Regulatory Compliance: Adherence to Standards and Regulations

Compliance with industry standards and regulations is crucial for the safe and efficient use of New Energy Steel Pipes systems:

- Material Standards: Ensuring the steel meets the required specifications for strength, durability, and corrosion resistance.

- Installation Guidelines: Adhering to best practices for pipe installation to prevent leaks and ensure structural integrity.

- Safety Protocols: Implementing safety measures to protect workers and the environment during installation and operation.

Safety Measures: Ensuring Safety in Steel Pipe Installations

Safety is a top priority in the installation and operation of steel pipes:

- Personal Protective Equipment (PPE): Providing workers with appropriate safety gear to protect against hazards.

- Risk Assessments: Conducting thorough risk assessments to identify potential hazards and implement mitigation measures.

- Emergency Preparedness: Developing and practicing emergency response plans to address incidents quickly and effectively.

Market Trends: Emerging Trends in Steel Pipe Utilization

Several trends are shaping the future of steel pipe utilization in the new energy sector:

- Increased Demand for Renewable Energy: The global shift towards renewable energy sources is driving demand for steel pipes.

- Technological Innovations: Advances in materials and manufacturing processes are enhancing the performance and efficiency of steel pipes.

- Sustainability Initiatives: Growing emphasis on sustainability is leading to the development of more eco-friendly steel pipe solutions.

Case Studies: Success Stories of New Energy Steel Pipes

Examining real-world examples of successful steel pipe applications provides valuable insights into best practices:

- Wind Farm Project: Highlighting the use of steel pipes in the construction of wind turbine towers, showcasing their strength and durability.

- Solar Thermal Plant: Discussing the role of steel pipes in transporting heat-transfer fluids, demonstrating their efficiency and reliability.

- Geothermal Installation: Showcasing the use of steel pipes in geothermal wells, emphasizing their resistance to high temperatures and pressures.

Future Prospects: Growth Potential and Future Outlook

The future of steel pipes in the new energy sector is promising, with several growth opportunities:

- Expansion of Renewable Energy Projects: Continued investment in renewable energy infrastructure will drive demand for steel pipes.

- Technological Advancements: Ongoing innovations in materials and design will enhance the performance and applicability of steel pipes.

- Global Sustainability Goals: The push towards sustainability will increase the adoption of steel pipes in environmentally friendly energy systems.

Expert Opinions: Insights from Industry Experts

Industry experts provide valuable insights into the role of New Energy Steel Pipes:

- Material Scientists: Discussing the latest advancements in steel alloys and coatings.

- Energy Engineers: Sharing experiences and best practices for integrating steel pipes into energy systems.

- Environmental Analysts: Highlighting the sustainability benefits of using steel pipes in renewable energy projects.

Conclusion: Summary of Steel Pipes’ Role in New Energy

Steel pipes are integral to the development and operation of new energy systems, offering strength, durability, and efficiency. As the world continues to transition towards sustainable energy sources, the demand for steel pipes will grow, driven by technological advancements and the need for reliable infrastructure. By understanding the key considerations, innovations, and trends in steel pipe utilization, industries can ensure the successful implementation of these essential components in their energy projects.