API 1104 Sources of Piping and Related Facilities

June 29, 2022

Piping System Inspection

June 29, 2022The API 5L standard and specification, developed by the American Petroleum Institute (API), covers oil, gas, and water pipelines in the oil, gas, and water distribution industries. The full name of the standard is as follows: API 5L Pipe Inspection and Testing.

According to this standard, pipes are classified according to the following criteria:

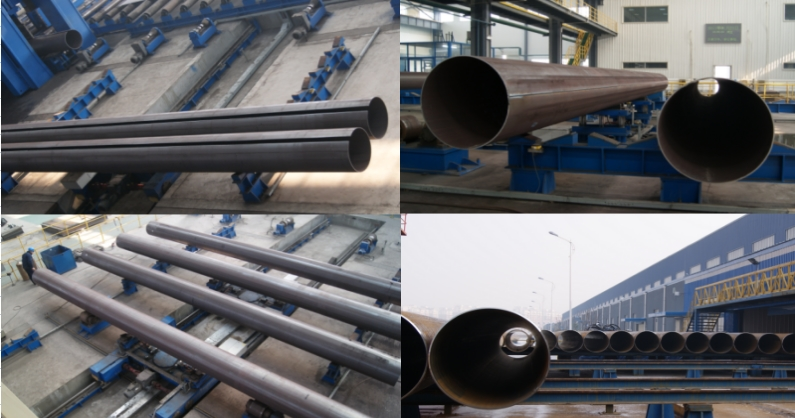

- Application: Seamless or Welded (Seamless pipe can be used up to 24 inches, LSAW can be used up to 24 inches, ERW can be used up to 20 inches)

- Specification level: API PSL1 is the standard quality for piping, API PSL2 sets more stringent chemical, mechanical properties and testing requirements

- Surface quality: black, varnish, anti-rust oil, galvanized, exterior coated and interior primed

- Tip Type: Straight, Angled, Threaded Tip

The main advantages of API 5L compliant pipes are:

- Resists cracking forces that can propagate in longer pipes

- Strict service availability

- Inexpensive and long service life

Pipe size and weight are the same in the American Petroleum Institute API 5L standard and the American Society of Mechanical Engineers ASME B36.10 standard.

Companies producing steel pipes require an API 5L audit from an authorized body to assess their ability to meet API 5L standards. Pipe plants that successfully pass this audit will receive an API monogram. This letter combination is valid for the expiration date.

In short, the API 5L specification for line pipe by the American Petroleum Institute sets requirements for seamless and welded steel pipes used in oil and gas transmission systems. This certification program requires detailed testing, including hydrostatic testing, non-destructive testing, and destructive testing. Compliant with API 5L standardIt saves the cost of steel pipe projects for enterprises.

Services provided by our organization within the framework of metal testing services include API 5L standard testing.

Select Differences Between PSL 1 & PSL 2

| Attributes | PSL 1 | PSL 2 | |

|---|---|---|---|

| CVN impact (Charpy) testing | None required | Required for all grades | |

| Nondestructive Inspection of Seamless | Only when purchaser specifies SR4 | SR4 mandatory | |

| Certification | Certificates when specified per SR15 | Certificates (SR 15.1) mandatory | |

| Traceability | Traceable only until all tests are passed, unless SR15 is specified | Traceable after completion of tests (SR 15.2) mandatory | |

| Hydrostatic Test | Required | Required | |