Piping System Inspection

June 29, 2022

Numerical simulation of cold drawing of steel tubes with straight internal rifling

June 29, 2022Natural gas pipe mainly contains a gas mixture called methane. Natural gas is formed by chemical changes in the remains of plants and animals that existed millions of years ago and remains deep in the Earth’s crust over time under the influence of heat and pressure. Natural gas pipe is usually found in oil-bearing or non-oil-bearing reservoirs.

Today, natural gas is used as an important energy source for heating homes and workplaces, and given the risks posed by natural gas, gas piping system installation inspections by authorised agencies are important in this regard.

Natural gas installations are used for residential heating, hot water production and kitchen stoves. In commercial enterprises, they are also used in productive activities.

The natural gas internal installation covers the entire system from the gas delivery point (service box) to the chimney, which discharges the exhaust gas piping system into the air. It basically consists of three parts: the building connection line (this line is the line from the service box to the main shut-off valve at the entrance of the building), the columnar line (the line is the line from the main shut-off valve to the metering valve) and the plane Installation (line from metering valve to furnace).

Steel pipes used in natural gas piping system installations comply with TS 6047, EN 10208 or ISO 3183 standards.Copper pipes must comply with TS 9872 EN 1057 standard. Welded fittings and flanges must comply with TS 2649, TS 11 EN 10242 and TS ISO 7005-1 standards, and ball valves must comply with TS EN 331 and TS 9809 standards.

In addition, it includes inspection of natural gas installations, underground piping, cathodic protection applications, tightness testing, placing pipes, connecting pipes, natural gas meters, gas consumers, chimneys, boiler room ventilation, electrical installation, and inspection of burner and gas control lines.

Our organization also provides gas piping system installation inspection services within the scope of mechanical installation inspection services.

Line Pipe For Gas Piping System

Line pipes are mostly used for transportation of gas, water, oil in petroleum,and natural gas industry.

API SPEC 5L (pipeline specification), the American Petroleum Institute prepared and published all over the world-wide.

Oil, gas or water extracted from ground is transported to the oil and gas industry companies through pipeline. It includes seamless and welded pipe, and has plain, threaded and socket end; it is connected to the tip welding, coupling connection, socket connections. Steel grade of line pipes are mainly GR.B, X42, X46, X56, X65, X70, X80, etc.

Seamless GAS Pipe

Steel Grade: B, X42, X52, X60, X65, X70

Dimension: 1″/2″—24″

Process: HOT ROLLING, Hot Expanding, SSAW

Steel Grade: B, X42, X52, X60, X65, X70, X80

Dimension: 5″ — 48″

Process: SSAW

Welding Gas Pipe

Steel Grade: B, X42, X52, X60, X65, X70, X80

Dimension: 2“–30”

Process: ERW, SAWL, HFW, JCOE

And, Anson can also provide anti-corrosion process for line pipes, which according to DIN30670, AWWA210 standard, such as the process FBE, 3PE, which can also be called as 3PP, 3LPP.

Mechanical Properties:

| Standard | Grade | Tensile(Mpa) | Yield(Mpa) | Yield Ratio | Elongation(%) | 0℃ Impact Akv(J) | Heat Treatment |

|---|---|---|---|---|---|---|---|

| API SPEC 5L | B | ≥415 | 245~440 | ≤0.80 | 22 | ≥40 | N |

| API SPEC 5L | X42 | ≥415 | 290~440 | ≤0.80 | 21 | ≥40 | N |

| API SPEC 5L | X52 | ≥460 | 360~510 | ≤0.85 | 20 | ≥40 | N |

| API SPEC 5L | X60 | ≥520 | 415~565 | ≤0.85 | 18 | ≥40 | N |

| API SPEC 5L | X65 | ≥535 | 450~570 | ≤0.90 | 18 | ≥40 | H+T |

| API SPEC 5L | X70 | ≥570 | 485~605 | ≤0.90 | 18 | ≥40 | H+T |

Chemical composition:

| Standard | Grade | Composition(%) | CEV(%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | V | Nb | Ti | |||

| API SPEC 5L | B | ≤0.16 | ≤0.40 | ≤1.10 | ≤0.020 | ≤0.010 | - | - | - | ≤0.42 |

| API SPEC 5L | X42 | ≤0.17 | ≤0.40 | ≤1.20 | ≤0.020 | ≤0.010 | ≤0.05 | ≤0.05 | ≤0.04 | ≤0.42 |

| API SPEC 5L | X52 | ≤0.20 | ≤0.45 | ≤1.60 | ≤0.020 | ≤0.010 | ≤0.10 | ≤0.05 | ≤0.04 | ≤0.45 |

| API SPEC 5L | X60 | ≤0.21 | ≤0.45 | ≤1.60 | ≤0.020 | ≤0.010 | ≤0.15 | ≤0.05 | ≤0.04 | ≤0.45 |

| API SPEC 5L | X65 | ≤0.16 | ≤0.45 | ≤1.60 | ≤0.020 | ≤0.010 | ≤0.06 | ≤0.05 | ≤0.06 | ≤0.45 |

| API SPEC 5L | X70 | ≤0.16 | ≤0.45 | ≤1.70 | ≤0.020 | ≤0.010 | ≤0.06 | ≤0.05 | ≤0.06 | ≤0.45 |

Remark:

1.0.015%≤Altot<0.06%;N≤0.012%;Al/N≥2/1;Cu≤0.25%;Ni≤0.30%;Cr≤0.30%;Mo≤0.10%

2.V+Nb+Ti≤0.15

3.X60、X65、X70-Mo≤0.35%

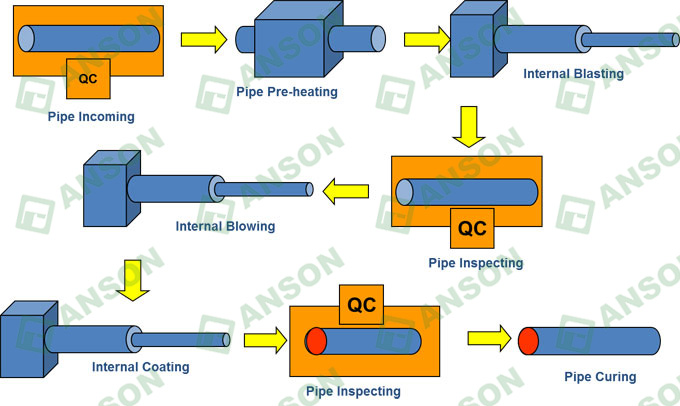

Flow chart of inside corrosion resistance technology

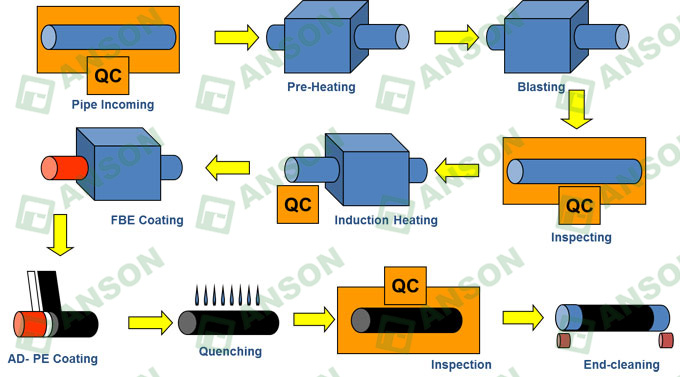

Flow chart of outside corrosion resistance technology

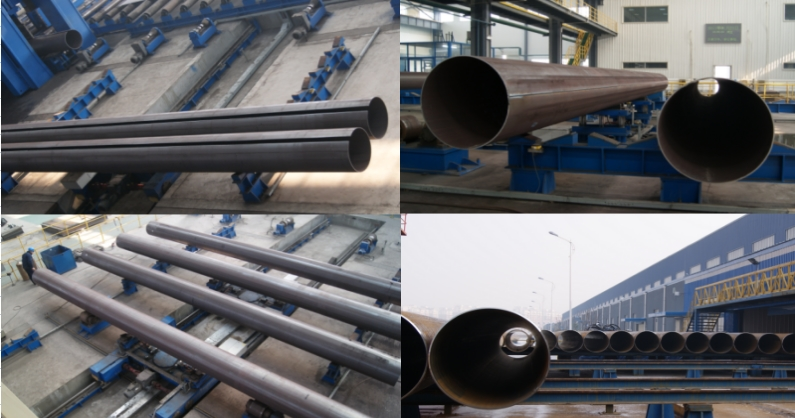

Productive process of linepipe

A . Seamless Pipes

- 1. Ingot heating

- 2. Perforation

- 3. Rolling and sizing

- 4. Cooling

- 5. Straightener

- 6. NDT, UT

- 7. End cutting

- 8. Coupling thread (permium thread available)

- 9. Hydrostatic test, x-ray test.

- 10. Painting and thread protecting

- 11. Packing

B. Welding Pipes

- 1. Open

- 2. Cutting

- 3. Welding

- 4. Shaping

- 5. Polishing

- 6. Correcting

- 7. Heat treatment

- 8. Eddy Current Test, Cutting

- 9. HT

- 10. Pickling and inspection

- 11. Painting, packing.