The difference between ERW steel pipe and spiral steel pipe

June 3, 2018Copper Fittings inspection report

June 29, 2018“Schedule 40” and “Schedule 80” refer to the thickness of the walls of pipes. “Schedule” is the standard of wall thickness that has been adopted by the American National Standards Institute. As per the Institute, the thickness of wall pipes varies from Schedule 10, Schedule 40, Schedule 80, and Schedule 160.

Pipes with Schedule 40 come with standard weight, and pipes with schedule 80 come with extra strength. The materials used for making Schedule 40 and Schedule 80 come from the same material.

Schedule 80 pipes have a thicker wall than Schedule 40 pipes. As such, Schedule 80 pipes are stronger than Schedule 40 pipes. Though both pipes are used in construction work, Schedule 40 is used more often. But if a stronger pipe was needed, then the engineers would go for Schedule 80 pipes. Schedule 80 pipes are used where the pipes have to be exposed. But if there is no need for any extra strength, Schedule 40 pipes are sufficient.

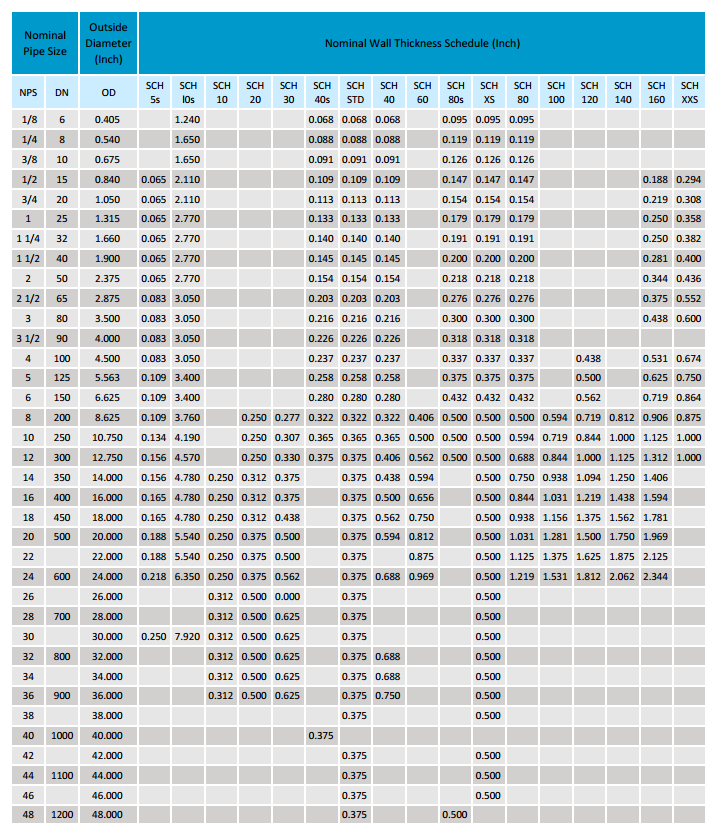

Steel Pipe Schedule Chart ANSI B36.10 & 36.19 (Unit in Inch)

Steel Pipe Dimensions Chart (Size Chart)

Schedule 40 and Schedule 80 pipes are also different in their cost. As Schedule 80 pipes consist of more materials, the price is considerably higher than Schedule 40 pipes. Schedule 80 pipes are also more costly as the cost of production is greater.

When comparing the weight, Schedule 40 pipes come in less weight than Schedule 80 pipes. As such, Schedule 40 pipes are easier to install than Schedule 80 pipes.

If there is a need for a high water temperature or high-pressure pipe, Schedule 80 is the best as it can withstand a greater pressure and temperature than Schedule 40 pipes.

What is Steel Pipe Dimensions Schedule?

Steel pipe schedule is a indicating method represented by ASME B 36.10, and also used in many other standards, marked with “Sch”. Sch is the abbreviation of schedule, generally appearing in the American steel pipe standard, which is a prefix of a series number. For example, Sch 80, 80 is a pipe number from chart/table ASME B 36.10.

“Since the steel pipe main application is to transport the fluids under pressure, so their internal diameter is their critical size. This critical size is taken as nominal bore (NB). Therefore, if steel pipe carry the fluids with pressure, it is very important that pipe shall have enough strength and enough wall thickness. So wall thickness is specified in Schedules, which means the pipe schedule, abbreviated as SCH. Here ASME is the given standard and definition for the pipe schedule.”

The pipe schedule formula:

Sch.=P/[ó]t×1000

P is the Designed pressure, units in MPa;

[ó]t is Allowable stress of materials under design temperature, Units in MPa.

What does SCH mean for the steel pipe dimensions

As describing the steel pipe parameter, we usually use the pipe schedule, It is a method that represent pipe wall thickness with number. Pipe schedule ( sch. ) is not a wall thickness, but a wall thickness series. Different pipe schedule means different wall thickness for the steel pipe in the same diameter. The most frequently indications of schedule are SCH 5, 5S, 10, 10S, 20, 20S, 30, 40, 40S, 60, 80, 80S, 100, 120, 140, 160. The larger the table number, the thicker the surface pipe wall, the higher the pressure resistance.

Schedule 40, 80 steel pipe dimension means

If you are new in pipe industry, why you always see a schedule 40 or 80 steel pipe everywhere? What kind of material for these pipes?

As you have read above articles you know that Schedule 40 or 80 represent a pipe wall thickness, but why it always been searched by buyers?

Here is the reason:

Schedule 40 and 80 steel pipe as the common sizes that required in different industries, because of the generally pressure these pipes bear, they are always been asked for a large quantity.

The material standard for such thickness pipes has no limitations, you could ask sch 40 stainless steel pipe, like ASTM A312 Grade 316L; Or sch 40 carbon steel pipe, such as API 5L, ASTM A53, ASTM A106B, A 179, A252, A333 etc..

Summary:

Pipes with Schedule 40 come with a standard weight, and pipes with Schedule 80 come with extra strength.

Schedule 80 pipes are stronger than Schedule 40 pipes.

Though both pipes are used in construction work, Schedule 40 is used more often.

Schedule 80 pipes are used where the pipes have to be exposed. But if there is no need for any extra strength, Schedule 40 pipes are sufficient.

When comparing the weight, Schedule 40 pipes come in less weight than Schedule 80 pipes.

As Schedule 80 pipes consist of more materials, the price is considerably higher than Schedule 40 pipes.

If there is a need for a high water temperature or high-pressure pipe, Schedule 80 is the best as it can withstand a greater pressure and temperature than Schedule 40 pipes.