Low-temperature seamless steel pipe standard

February 10, 2018Carbon Steel pipe Bollards – Steel Pipe Security for Building Perimeters

February 20, 2018Hot-rolled seamless steel pipes and cold-rolled seamless steel pipes are formed by the process of steel or steel plate, they have a great impact on the microstructure and properties of steel, the rolling mill is mainly hot-rolled, cold-rolled only for the production of small steel and sheet.

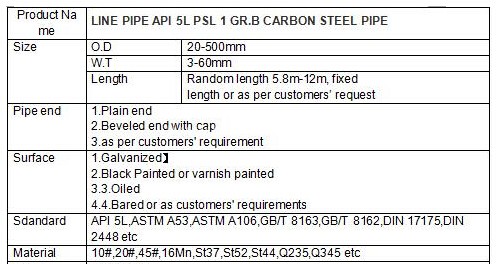

Description:

| Standard | ASTM A106, ASTM A53, API 5L Gr.B, DIN17175, etc |

| Material | ASTM A106B, ASTM A53B, ST52, ST37, ST44, ST45, etc |

| Outer Diameter | 20mm – 610mm |

| Wall Thickness | 2 mm – 70mm |

| Length | 3-12m, random or fixed, as the clients’ requests |

| Technology | Cold drawn or Hot rolled |

| Tolerance | Control with in the standard, OD:+-1%, WT:+-10% |

The advantages and disadvantages of hot-rolled steel pipe and cold-rolled steel pipe are described below.

Hot rolled

Advantages:

It can destroy the casting microstructure of the ingot, refine the grain of steel, and eliminate the defects of microstructure, so that the steel structure is dense and the mechanical properties are improved.

This improvement is mainly reflected in the rolling direction, so that the steel to a certain extent is no longer isotropic body, the formation of the pouring bubble, crack and loose, can also be welded under the action of high temperature and pressure.

Shortcomings:

1. After hot-rolling, non-metallic inclusions in the steel (mainly sulfide and oxides, as well as silicate) are pressed into thin slices, the phenomenon of delamination (interlayer) occurs. Delamination greatly worsens the tensile properties of the steel along the thickness direction, and it is possible to have interlayer tearing during the contraction of the weld. The local strain induced by the weld contraction often reaches several times of the yield point strain, which is much larger than the strain caused by the load.

2. Residual stress caused by uneven cooling. Residual stress is the internal self equilibrium stress in the absence of external force, and all kinds of hot-rolled steels have such residual stresses, the larger the general section size of steel and the greater the residual stress. Although the residual stress is a self equilibrium, it has some influence on the performance of the steel member under the external force, such as deformation, stability, anti-fatigue and other aspects may have adverse effects.

Cold Rolled

Cold rolling refers to the steel plate or steel strip processed into various types of steel by cold drawing, Leng, drawing and so on at room temperature.

Advantages:

Rapid molding speed, high yield, and no damage to the coating, can be made into a variety of cross-section forms to meet the needs of the use of conditions;

Shortcomings:

Product description

Application

1. Low and middle pressure fluid transportation pipeline

2. Casing Tube

3. Boiler Pipe

4. Petroleum and natural gas industry

5. Chemistry industry

6. Electric industry

1. Although the molding process has not undergone thermal plastic compression, but there is still residual stress in the section, the overall and local buckling properties of steel will inevitably have an impact.

2. The cold rolled section style is generally open section, which makes the free torsional stiffness of the section lower.

It is easy to twist when bending, bending and torsional buckling is easy to appear under pressure, and torsional performance is poor.

3. Cold-rolled steel wall thickness is small, the joint of the plate is not thickened at the corner, the ability to withstand local concentrated load weak.

Three. The main differences between hot and cold rolling

1. The partial buckling of the allowable section of cold rolled steel can make full use of the buckling load of the rod, while the hot-rolled steel section does not allow local buckling.

2, the reasons for the residual stress of hot rolled and cold rolled steel are different, so the distribution on the section is also very big difference.

The residual stress distribution of cold-formed thin-walled steel section is curved, while the residual stress distribution on hot-rolled or welded section is film type.

3. The free torsional stiffness of hot rolled steel is higher than that of cold-rolled steel, so the torsion resistance of hot rolled steel is better than that of cold-rolled steel.