DUPLEX STEEL 2205 PIPE | UNS S31803 PIPE

December 12, 2023

Incoloy 800 Alloy Seamless steel Pipe

December 21, 2023ASTM A182 Stainless Steel Flanges

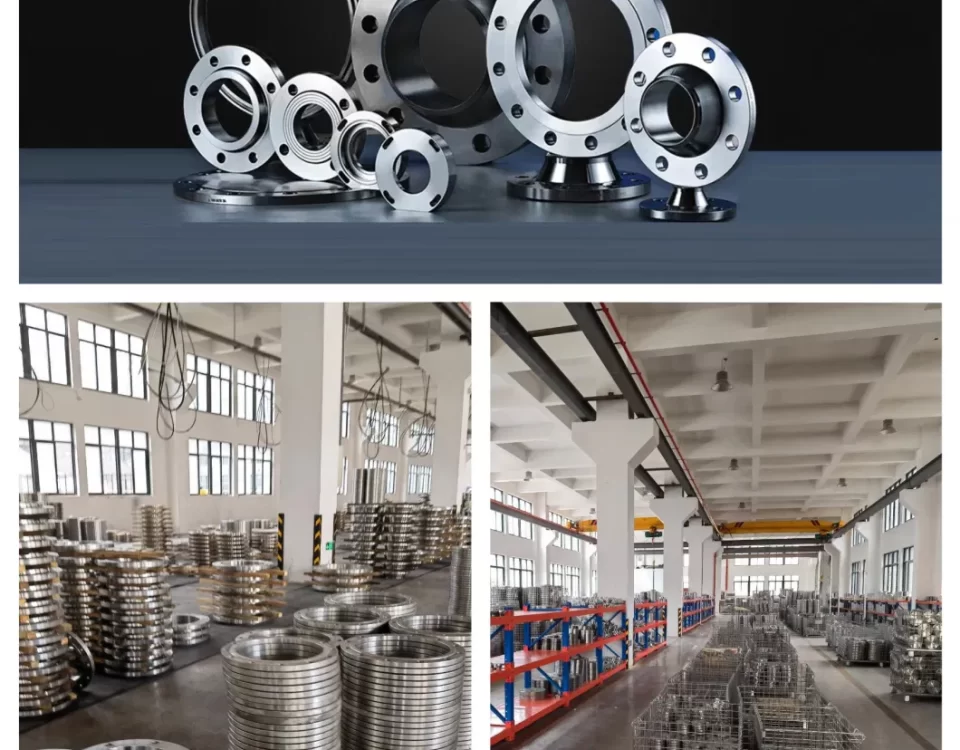

Introduction

ASTM A182 is a specification that covers forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves and parts for high-temperature service. In this article, we will focus on ASTM A182 stainless steel flanges and explore their features, uses, and benefits in various industries.

1. Features of ASTM A182 Stainless Steel Flanges

ASTM A182 stainless steel flanges exhibit several key features that make them highly desirable in different applications:

- Corrosion Resistance: Stainless steel is known for its excellent corrosion resistance properties, making ASTM A182 flanges suitable for environments where exposure to moisture, chemicals, or corrosive substances is expected.

- High Strength: The forging process used in manufacturing ASTM A182 flanges ensures their strength and durability, allowing them to withstand high-pressure and high-temperature conditions.

- Versatility: ASTM A182 stainless steel flanges are available in various grades, such as 304, 316, 321, and 347, offering versatility in terms of chemical composition and performance.

- Excellent Weldability: Stainless steel flanges made according to the ASTM A182 specification can be easily welded, providing flexibility during installation and maintenance.

2. Uses of ASTM A182 Stainless Steel Flanges

ASTM A182 stainless steel flanges find applications in a wide range of industries, including:

- Oil and Gas: These flanges are commonly used in oil refineries, offshore platforms, and petrochemical plants, where they provide reliable connections in pipelines, valves, and equipment.

- Chemical Processing: ASTM A182 flanges are suitable for chemical processing plants, where they are used to connect pipes and equipment that handle corrosive substances.

- Power Generation: Flanges made from stainless steel are widely used in power plants, including nuclear, thermal, and renewable energy facilities, due to their ability to withstand high temperatures and pressures.

- Food and Beverage: The hygienic properties of stainless steel make ASTM A182 flanges ideal for applications in the food and beverage industry, where cleanliness and corrosion resistance are essential.

- Pharmaceutical: In pharmaceutical manufacturing, where strict quality and cleanliness standards must be met, stainless steel flanges are commonly used to ensure a safe and reliable process.

3. Benefits of ASTM A182 Stainless Steel Flanges

The use of ASTM A182 stainless steel flanges provides several benefits, including:

- Longevity: Stainless steel is known for its long lifespan, offering durability and reliability over an extended period.

- Corrosion Resistance: ASTM A182 stainless steel flanges are resistant to corrosion, reducing the risk of leaks, system failures, and maintenance costs.

- Hygienic Properties: Stainless steel is easy to clean and maintain, making it suitable for industries with strict hygiene requirements, such as food and pharmaceutical processing.

- Compatibility: ASTM A182 flanges can be easily connected to pipes, valves, and other equipment, ensuring compatibility and ease of installation.

- Versatility: With a range of stainless steel grades available, ASTM A182 flanges can be selected to meet specific requirements, such as high-temperature or high-pressure applications.

Conclusion

ASTM A182 stainless steel flanges offer exceptional corrosion resistance, high strength, and versatility for various industries. Their use in oil and gas, chemical processing, power generation, food and beverage, and pharmaceutical sectors demonstrates their reliability and suitability for demanding environments. With their longevity, corrosion resistance, and compatibility, ASTM A182 stainless steel flanges provide a reliable and efficient solution for connecting pipes and equipment in critical applications.

Equivalent Grades of ASTM A182 Stainless Steel Flanges

1. Grade 304 Stainless Steel Flanges

Grade 304 stainless steel flanges are the most commonly used flanges in the ASTM A182 specification. They offer excellent corrosion resistance in a wide range of environments and are suitable for applications requiring strength and durability. The equivalent grades for Grade 304 stainless steel flanges include:

- UNS S30400

- DIN 1.4301

- X5CrNi18-10

- JIS SUS304

2. Grade 316 Stainless Steel Flanges

Grade 316 stainless steel flanges provide superior corrosion resistance, especially in chloride-rich environments. They are commonly used in industries such as marine, chemical processing, and pharmaceuticals. The equivalent grades for Grade 316 stainless steel flanges include:

- UNS S31600

- DIN 1.4401

- X5CrNiMo17-12-2

- JIS SUS316

3. Grade 321 Stainless Steel Flanges

Grade 321 stainless steel flanges offer excellent resistance to high temperatures and are often used in applications involving continuous exposure to elevated temperatures. The equivalent grades for Grade 321 stainless steel flanges include:

- UNS S32100

- DIN 1.4541

- X6CrNiTi18-10

- JIS SUS321

4. Grade 347 Stainless Steel Flanges

Grade 347 stainless steel flanges have similar characteristics to Grade 321 flanges but offer enhanced resistance to intergranular corrosion. They are commonly used in applications where high temperatures and frequent thermal cycling occur. The equivalent grades for Grade 347 stainless steel flanges include:

- UNS S34700

- DIN 1.4550

- X6CrNiNb18-10

- JIS SUS347

5. Other Stainless Steel Grades

Apart from the above-mentioned grades, there are several other stainless steel grades that can be used for ASTM A182 flanges. Some of these grades include:

- Grade 304L (UNS S30403, DIN 1.4306)

- Grade 316L (UNS S31603, DIN 1.4404)

- Grade 904L (UNS N08904, DIN 1.4539)

- Grade 317L (UNS S31703, DIN 1.4438)

Conclusion

Understanding the equivalent grades of ASTM A182 stainless steel flanges allows for the selection of the most suitable material based on specific requirements. Whether it’s Grade 304, Grade 316, Grade 321, Grade 347, or other stainless steel grades, each offers unique characteristics and advantages in terms of corrosion resistance, strength, and temperature resistance. By considering the equivalent grades, professionals can confidently choose the right stainless steel flanges for their applications, ensuring optimal performance and longevity.

ASTM A182 Stainless Steel Butt Weld Flanges Chemical Composition

1. Chemical Composition of Grade 304 Stainless Steel Butt Weld Flanges

Grade 304 stainless steel butt weld flanges have the following chemical composition:

- Carbon (C): 0.08% maximum

- Manganese (Mn): 2.00% maximum

- Phosphorus (P): 0.045% maximum

- Sulfur (S): 0.030% maximum

- Silicon (Si): 0.75% maximum

- Chromium (Cr): 18.0-20.0%

- Nickel (Ni): 8.0-11.0%

Grade 304 stainless steel is a versatile and widely used stainless steel grade due to its excellent corrosion resistance, formability, and weldability.

2. Chemical Composition of Grade 316 Stainless Steel Butt Weld Flanges

Grade 316 stainless steel butt weld flanges have the following chemical composition:

- Carbon (C): 0.08% maximum

- Manganese (Mn): 2.00% maximum

- Phosphorus (P): 0.045% maximum

- Sulfur (S): 0.030% maximum

- Silicon (Si): 0.75% maximum

- Chromium (Cr): 16.0-18.0%

- Nickel (Ni): 10.0-14.0%

- Molybdenum (Mo): 2.0-3.0%

Grade 316 stainless steel offers superior corrosion resistance, particularly in chloride-rich environments, making it suitable for marine, chemical processing, and pharmaceutical applications.

3. Chemical Composition of Grade 321 Stainless Steel Butt Weld Flanges

Grade 321 stainless steel butt weld flanges have the following chemical composition:

- Carbon (C): 0.08% maximum

- Manganese (Mn): 2.00% maximum

- Phosphorus (P): 0.045% maximum

- Sulfur (S): 0.030% maximum

- Silicon (Si): 0.75% maximum

- Chromium (Cr): 17.0-19.0%

- Nickel (Ni): 9.0-12.0%

- Titanium (Ti): 5x(C+N) minimum, 0.70% maximum

Grade 321 stainless steel offers excellent resistance to high temperatures and is often used in applications involving continuous exposure to elevated temperatures.

4. Chemical Composition of Grade 347 Stainless Steel Butt Weld Flanges

Grade 347 stainless steel butt weld flanges have the following chemical composition:

- Carbon (C): 0.08% maximum

- Manganese (Mn): 2.00% maximum

- Phosphorus (P): 0.045% maximum

- Sulfur (S): 0.030% maximum

- Silicon (Si): 0.75% maximum

- Chromium (Cr): 17.0-19.0%

- Nickel (Ni): 9.0-13.0%

- Columbium (Nb) + Tantalum (Ta): 10x(C+N) minimum, 1.00% maximum

Grade 347 stainless steel offers enhanced resistance to intergranular corrosion and is commonly used in applications where high temperatures and frequent thermal cycling occur.

Conclusion

The chemical composition of ASTM A182 stainless steel butt weld flanges, such as Grade 304, Grade 316, Grade 321, and Grade 347, plays a crucial role in determining their unique properties. The varying amounts of carbon, manganese, phosphorus, sulfur, silicon, chromium, nickel, and additional elements like molybdenum, titanium, columbium, and tantalum contribute to their corrosion resistance, strength, and temperature resistance. Understanding the chemical composition allows professionals to select the appropriate grade of stainless steel butt weld flanges for their specific