ASTM B861, B862, and B338 Titanium Pipe

April 3, 2024

Bridge Slot Screen Pipe: A Versatile Solution for Filtration and Well Completion

April 11, 2024Long Radius Elbow, Short Radius Elbow, LR Elbow, SR Elbow: Understanding the Differences

In the world of piping and plumbing, different types of elbows are used to change the direction of flow in a pipeline. Two common types of elbows are the Long Radius (LR) elbow and the Short Radius (SR) elbow. These terms, LR elbow and SR elbow, are often used interchangeably, but it’s important to understand the differences between them.

Long Radius Elbow (LR Elbow)

A Long Radius (LR) elbow is an elbow with a larger radius of curvature compared to a Short Radius (SR) elbow. The radius of curvature for an LR elbow is typically 1.5 times the nominal pipe size (NPS). For example, if you have a 6-inch pipe, the radius of curvature for an LR elbow would be 9 inches.

The advantage of using an LR elbow is that it provides a smoother flow path for the fluid or gas passing through the pipeline. The larger radius allows for a gradual change in direction, reducing the risk of turbulence and pressure drop. This makes LR elbows suitable for applications where flow efficiency is crucial, such as in high-velocity systems or systems with abrasive fluids.

Short Radius Elbow (SR Elbow)

A Short Radius (SR) elbow, on the other hand, has a smaller radius of curvature compared to an LR elbow. The radius of curvature for an SR elbow is typically equal to the nominal pipe size (NPS). Using the same example as before, a 6-inch pipe would have a 6-inch radius of curvature for an SR elbow.

SR elbows are often used in tight spaces or when there are space constraints in the piping system. Due to their smaller radius, SR elbows create a sharper change in direction, which can result in higher pressure drop and increased turbulence. Therefore, they are not recommended for applications where flow efficiency is critical.

| Nominal pipe size | Outside Diameter at Bevel |

Center to End | Center to Center | Back to Faces | ||||||

| 45°Elbows | 90°Elbows | 180°Return | ||||||||

| H | F | P | K | |||||||

| DN | INCH | Series A | Series B | LR | LR | SR | LR | SR | LR | SR |

| 15 | 1/2 | 21.3 | 18 | 16 | 38 | – | 76 | – | 48 | – |

| 20 | 3/4 | 26.9 | 25 | 16 | 38 | – | 76 | – | 51 | – |

| 25 | 1 | 33.7 | 32 | 16 | 38 | 25 | 76 | 51 | 56 | 41 |

| 32 | 11/4 | 42.4 | 38 | 20 | 48 | 32 | 95 | 64 | 70 | 52 |

| 40 | 11/2 | 48.3 | 45 | 24 | 57 | 38 | 114 | 76 | 83 | 62 |

| 50 | 2 | 60.3 | 57 | 32 | 76 | 51 | 152 | 102 | 106 | 81 |

| 65 | 21/2 | 76.1(73) | 76 | 40 | 95 | 64 | 191 | 127 | 132 | 100 |

| 80 | 3 | 88.9 | 89 | 47 | 114 | 76 | 229 | 152 | 159 | 121 |

| 90 | 31/2 | 101.6 | – | 55 | 133 | 89 | 267 | 178 | 184 | 140 |

| 100 | 4 | 114.3 | 108 | 63 | 152 | 102 | 305 | 203 | 210 | 159 |

| 125 | 5 | 139.7 | 133 | 79 | 190 | 127 | 381 | 254 | 262 | 197 |

| 150 | 6 | 168.3 | 159 | 95 | 229 | 152 | 457 | 305 | 313 | 237 |

| 200 | 8 | 219.1 | 219 | 126 | 305 | 203 | 610 | 406 | 414 | 313 |

| 250 | 10 | 273.0 | 273 | 158 | 381 | 254 | 762 | 508 | 518 | 391 |

| 300 | 12 | 323.9 | 325 | 189 | 457 | 305 | 914 | 610 | 619 | 467 |

| 350 | 14 | 355.6 | 377 | 221 | 533 | 356 | 1067 | 711 | 711 | 533 |

| 400 | 16 | 406.4 | 426 | 253 | 610 | 406 | 1219 | 813 | 813 | 610 |

| 450 | 18 | 457.2 | 478 | 284 | 686 | 457 | 1372 | 914 | 914 | 686 |

| 500 | 20 | 508.0 | 529 | 316 | 762 | 508 | 1524 | 1016 | 1016 | 762 |

| 550 | 22 | 559 | – | 347 | 838 | 559 | Note: 1. Do not use the figures in the parenthesis as far as possible 2. Please first select A series. |

|||

| 600 | 24 | 610 | 630 | 379 | 914 | 610 | ||||

| 650 | 26 | 660 | – | 410 | 991 | 660 | ||||

| 700 | 28 | 711 | 720 | 442 | 1067 | 711 | ||||

| 750 | 30 | 762 | – | 473 | 1143 | 762 | ||||

| 800 | 32 | 813 | 820 | 505 | 1219 | 813 | ||||

| 850 | 34 | 864 | – | 537 | 1295 | 864 | ||||

| 900 | 36 | 914 | 920 | 568 | 1372 | 914 | ||||

| 950 | 38 | 965 | – | 600 | 1448 | 965 | ||||

| 1000 | 40 | 1016 | 1020 | 631 | 1524 | 1016 | ||||

| 1050 | 42 | 1067 | – | 663 | 1600 | 1067 | ||||

| 1100 | 44 | 1118 | 1120 | 694 | 1676 | 1118 | ||||

| 1150 | 46 | 1168 | – | 726 | 1753 | 1168 | ||||

| 1200 | 48 | 1220 | 1220 | 758 | 1829 | 1219 | ||||

Differences and Applications

The main difference between LR elbows and SR elbows lies in their radius of curvature. LR elbows have a larger radius, providing a smoother flow path and lower pressure drop. SR elbows have a smaller radius, making them suitable for tight spaces but potentially causing higher pressure drop and increased turbulence.

When choosing between LR elbows and SR elbows, consider the specific requirements of your piping system. If flow efficiency is crucial and space permits, LR elbows are generally preferred. On the other hand, if space is limited and flow efficiency is not a primary concern, SR elbows can be a suitable choice.

, LR elbows and SR elbows are two types of elbows used in piping systems to change the direction of flow. LR elbows have a larger radius of curvature, providing a smoother flow path and lower pressure drop. SR elbows have a smaller radius of curvature, making them suitable for tight spaces but potentially causing higher pressure drop and increased turbulence.

Understanding the differences between LR elbows and SR elbows allows you to make informed decisions when selecting the appropriate elbow for your specific application. Consider factors such as flow efficiency, space constraints, and system requirements to ensure optimal performance and functionality in your piping system.

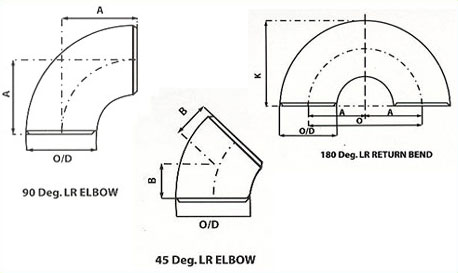

Understanding Different Types of Steel Pipe Elbows: 45 Degree, 90 Degree, and 180 Degree

In the world of piping and plumbing, steel pipe elbows are essential components used to change the direction of fluid flow. Among the various types of elbows available, the 45 degree, 90 degree, and 180 degree steel elbows are commonly used. Let’s explore each type in detail.

45 Degree Steel Elbow

A 45 degree steel elbow is designed to change the fluid direction by 45 degrees. This type of elbow is mounted between two pipes, allowing for a smooth transition in direction. Compared to a 90 degree elbow, a 45 degree elbow produces less friction and results in lower pressure drop. This makes it suitable for applications where maintaining a lower pressure is desired.

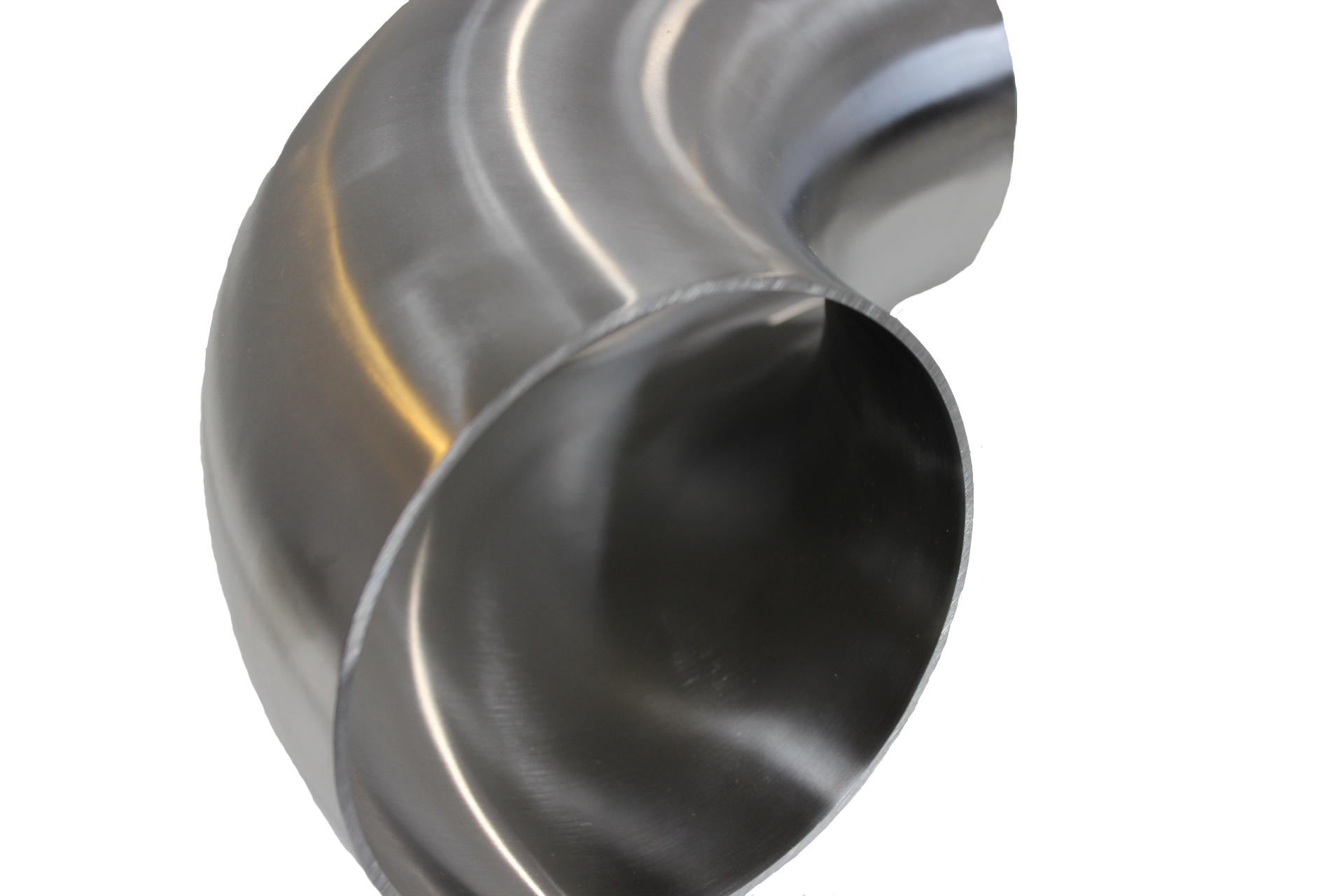

90 Degree Steel Elbow

The 90 degree steel elbow is one of the most commonly used types of elbows. It is available in two variations: the long radius (LR) 90 degree elbow and the short radius (SR) 90 degree elbow.

Long Radius 90 Degree Elbow

The long radius 90 degree elbow is installed between different lengths of pipe or tubing. It helps to change the direction of flow at a 90 degree angle. This type of elbow is commonly used to connect hoses to pumps, deck drains, and valves. Its larger radius of curvature allows for a smoother flow path, reducing pressure drop and minimizing turbulence.

Short Radius 90 Degree Elbow

The short radius 90 degree elbow, as the name suggests, has a shorter radius of curvature compared to the long radius elbow. It is often used in applications where space is limited. While it provides a sharper change in direction, it can result in higher pressure drop and increased turbulence. Therefore, it is recommended to use short radius elbows only when space constraints are a concern.

180 Degree Steel Elbow

The 180 degree steel elbow is designed to change the fluid direction by 180 degrees, effectively reversing the flow. This type of elbow is typically used in systems where minimal deposition and low turbulence are desired. Due to the significant change in direction, it usually results in low pressure.

Stainless Steel:304/304L, 316/316L,316Ti,321,317L,310S,etc

Alloy Steel:A335-P1,P2 ,P5 ,P11,P12 ,P22,P91,P92,A369-FP1,P2 A250-T1 A209-T1 A213-T2,T9 ,T12 A199-T11,T22,

Duplex Stainless Steel: S31803(SAF2205),S32750(SAF2507),S31500(3RE60)

| ASTM A234 | Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service |

| ASTM A420 | Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service |

| ASTM A403 | Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings |

| ASME B16.9 | Factory Made Wroght Steel Butt Welding Fittings |

ASTM A234

| Standard | Grade | C | Si | Mn | P | S | V | Nb | Ti | Cr | Mo | Ni | Al | Nb | N | Others |

| max | max | max | max | max | max | max | max | max | max | max | max | max | max | max | ||

| A234 | WPC | 0.28 | – | 1.20 | 0.030 | 0.030 | – | – | – | – | – | – | – | – | – | – |

| WPB | 0.28 | – | 1.20 | 0.030 | 0.030 | – | – | – | – | – | – | – | – | – | – | |

| WP11 | 0.05-0.15 | 0.50-1.0 | 0.30-0.60 | 0.025 | 0.025 | – | – | – | 1.00-1.50 | 0.44–0.65 | – | – | – | – | – | |

| WP22 | 0.05-0.15 | 0.50 | 0.30-0.60 | 0.025 | 0.025 | – | – | – | 1.90-2.60 | 0.87–1.13 | – | – | – | – | – | |

| WP5 | 0.15 | 0.50 | 0.30-0.60 | 0.025 | 0.025 | – | – | – | 4.00-6.00 | 0.45–0.65 | – | – | – | – | – | |

| WP9 | 0.15 | 0.25-1.0 | 0.30-0.60 | 0.025 | 0.025 | – | – | – | 8.00-10.00 | 0.90–1.10 | – | – | – | – | – | |

| WP91 | 0.08-0.12 | 0.20-0.50 | 0.30-0.60 | 0.020 | 0.010 | 0.18–0.25 | – | – | 8.00-9.50 | 0.85–1.05 | 0.40 | 0.04 | – | 0.03–0.07 | Cb 0.06–0.10 |

|

| WP92 | 0.07-0.13 | 0.5 | 0.30-0.60 | 0.020 | 0.010 | 0.15–0.25 | – | – | 8.50-9.50 | 0.30–0.60 | 0.40 | 0.04 | – | 0.03–0.07 | Cb 0.04–0.09 W 1.5–2.00 B 0.001–0.006 |

ASTM A420/A420M

| Steel No. | Type | Chemical composition | ||||||||||||

| C | Si | S | P | Mn | Cr | Ni | Mo | Other | ób | ós | δ5 | HB | ||

| WPL6 | 0.3 | 0.15-0.3 | 0.04 | 0.035 | 0.6-1.35 | 0.3 | 0.4 | 0.12 | Cb:0.02;V:0.08 | 415-585 | 240 | 22 | ||

| WPL9 | 0.2 | 0.03 | 0.03 | 0.4-1.06 | 1.6-2.24 | 435-610 | 315 | 20 | ||||||

| WPL3 | 0.2 | 0.13-0.37 | 0.05 | 0.05 | 0.31-0.64 | 3.2-3.8 | 450-620 | 240 | 22 | |||||

| WPL8 | 0.13 | 0.13-0.37 | 0.03 | 0.03 | 0.9 | 8.4-9.6 | 690-865 | 515 | 16 | |||||

Applications of Steel Pipe Elbows

Steel pipe elbows find applications in various industries and fields. Some common applications include:

- Chemical processing facilities

- Food industry

- Water supply systems

- Electronic industry

- Horticulture and agriculture production

- Solar equipment pipelines

- Air conditioning pipelines

These elbows are compatible with different materials such as copper, plastic, steel, cast iron, lead, stainless steel, and rubber fixtures, making them versatile for a wide range of applications.

Conclusion

Steel pipe elbows, including the 45 degree, 90 degree, and 180 degree elbows, play a crucial role in changing the direction of fluid flow in piping systems. The choice of the elbow type depends on factors such as space constraints, pressure requirements, and the desired flow path. Whether it’s for minimizing pressure drop, reducing turbulence, or reversing flow, selecting the appropriate steel elbow is essential for optimal system performance.

When selecting steel pipe elbows, it is important to consider the specific requirements of your application and consult with industry experts or reputable suppliers to ensure the proper fit and functionality. By understanding the differences and applications of various steel elbows, you can make informed decisions and ensure the success of your piping system.