Exploring the Advantages of Clad Pipe and Lined Pipe in Various Industries

December 31, 2023

Mechanically Lined Pipes: A Comprehensive Guide

January 11, 2024Are you ready to explore the key to unlocking efficiency and performance in boiler systems?

Imagine a world where boiler systems operate at peak efficiency, delivering optimal performance and energy savings. The key to unlocking this potential lies in one crucial component: ASTM A556 seamless steel boiler pipes. These pipes, designed to withstand high temperatures and pressure, play a vital role in various industries by ensuring reliable heat transfer and exceptional performance.

The ASTM A556 standard sets the specifications for seamless steel boiler pipes, outlining the requirements for their manufacturing, dimensions, and mechanical properties. By adhering to this standard, industries can be confident in the quality and reliability of these pipes, knowing they are built to withstand the demanding conditions of boiler systems.

The importance of reliable and high-quality boiler pipes cannot be overstated. In boiler systems, these pipes serve as conduits for the transfer of heat from the combustion process to the water or steam, enabling the generation of power or the provision of hot water. The efficiency of this heat transfer process directly impacts the overall performance and energy consumption of the boiler system.

When it comes to energy-intensive industries such as power generation, the role of ASTM A556 seamless steel boiler pipes becomes even more critical. These pipes have revolutionized the industry by enabling the construction of high-efficiency boilers that maximize the conversion of fuel into usable energy. By providing a reliable and robust conduit for heat transfer, these pipes ensure that the generated energy is efficiently utilized, minimizing waste and reducing environmental impact.

Let me share a compelling story or example of how ASTM A556 seamless steel boiler pipes have revolutionized a specific industry or project. Imagine a large-scale power plant project that required the construction of multiple high-pressure boilers. By utilizing these seamless steel pipes, the project achieved unparalleled efficiency and performance. The exceptional heat transfer capabilities of ASTM A556 pipes allowed for optimal energy generation, resulting in significant cost savings and reduced carbon emissions. This success story serves as a testament to the transformative power of reliable and high-quality boiler pipes.

The significance of ASTM A556 seamless steel boiler pipes extends beyond power generation. In industries such as oil refineries, chemical processing plants, and food processing facilities, these pipes play a crucial role in providing the necessary heat for various processes. Their reliability and durability ensure uninterrupted operations and consistent product quality.

In conclusion, ASTM A556 seamless steel boiler pipes are the key to unlocking efficiency and performance in boiler systems. By adhering to the standards set by this remarkable pipe specification, industries can ensure reliable heat transfer, optimal energy utilization, and exceptional performance. Whether it is power generation, oil refining, or chemical processing, the importance of reliable and high-quality boiler pipes cannot be overstated. Embracing the use of ASTM A556 seamless steel boiler pipes paves the way for enhanced efficiency, reduced environmental impact, and improved operational excellence in various industries.

ASME SA556 B2 Seamless Cold-Drawn Carbon Steel Feedwater Heater Tubes

ASME SA556 B2 SEAMLESS FEEDWATER HEATER TUBES

ASTM A556 Gr. A2 – B2 – C2, ASME SA556 Sect.II Gr. A2 – B2 – C2

“U” Bent tubes in accordance with the standards detailed in table 1, part A can be requested.

The bent area can be subject to stress relieving heat treatment by joule effect in inert atmosphere.

– Minimum radius treated = 28 mm.

– Maximum radius treated = 750 mm.

1. U bend Tube Bundle Dimensions and lengths

Tubes with the following external diameters in mm can be bent a upon agreement: 15,8 – 16,0 – 17,0 – 18,0 – 19,05 – 20,0 – 21,3 – 25,4 – 26,7 – 31,8 -38,1.

The minimum feasible radius is : 1,5 x external diameter

The maximum feasible radius is 1500 mm.

2. U bend Tube Bundle Tolerances

Tolerances (diameter and wall thickness) according to ASTM A 556 or given in the standards detailed in table 1 point A are respected.

Bending tolerances. The tolerances stipulated in ASTM A 556 are respected.

Minimum wall thickness tolerances in the bent area conforming to the TEMA standard “Class R heat exchangers” can be requested or in accordance with specific requests.

ASTM A556 SEAMLESS STEEL BOILER PIPE Chemistry Composition%

| Grade | C max | Mn | P max | S max |

| A2 | 0.18 | 0.27-0.63 | 0.035 | 0.035 |

| B2 | 0.27 | 0.29-0.93 | 0.030 | 0.030 |

| C2 | 0.30 | 0.29-1.06 | 0.030 | 0.030 |

ASTM A556 SEAMLESS STEEL BOILER PIPE Mechanical Properties

| Grade | Tensile Strength

MPa min |

Yield Strength

MPa min |

Elongation in 50mm % min |

| A2 | 47 (320) | 26(180) | 35 |

| B2 | 60(410) | 37(260) | 30 |

| C2 | 70 (480) | 40 (280) | 30 |

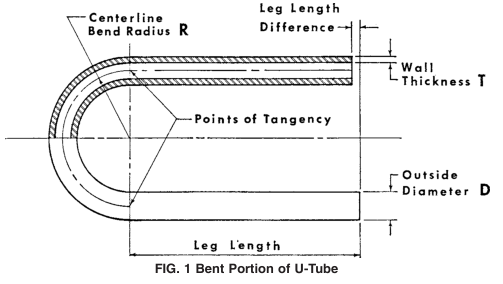

Permissible Variations in Dimensions (Fig. 1)

Permissible variations from the specified outside diameter shall not exceed 60.004 in. [0.10 mm] for tubing under1.0-in. [25.4-mm] outside diameter nor 60.006 in. [0.15 mm]for tubing 1.0 in. [25.4 mm] to 1.25 in. [31.7 mm] inclusive.These tolerances do not apply to the bent portion of the U-tubes. At the bent portion of a U-tube for R = 2 3 D or greater neither the major nor minor diameter of tube shall eviate from nominal by more than 10 %. If 1 1 ⁄ 2 D is specified, tolerances could be greater.

Permissible variations from the specified minimum wall thickness shall not exceed +20 % or −0. The wall thickness of the tube in U-bent section shall be not less than value determined by:

where:

t f = wall thickness after bending, in. [mm],

T = specified minimum tube wall thickness, in. [mm],

R = centerline bend radius, in. [mm], and

D = nominal outside tube diameter, in. [mm].

In the case of U-tubes, the length of the tube legs as measured from the point of tangency of the bend and the tube leg to the end ofthe tube leg shall not be less than specified, but may exceed the specified values by the amount given in Table 4. The difference in lengths of the tube legs shall not be greater than1 ⁄ 8 in. [3 mm] unless otherwise specified.

| Leg Length, ft [m] | Plus Tolerance in. [mm] |

| Up to 20 [6], incl | 1 ⁄ 8 [3.2] |

| Over 20 to 30 [6 to 9], incl | 5 ⁄ 32 [4.0] |

| Over 30 to 40 [9 to 12.2], incl | 3 ⁄ 1 6 [4.8] |

The end of any tube may depart from square by not more than the amount given in Table 5.

| Tube OD, in. [mm] | Tolerance, in. [mm] |

| 5 ⁄ 8[15.9] | 0.010 [0.25] |

| Over 5 ⁄ 8 to 1 1 ⁄ 4 [15.9 to 31.7], incl | 0.016 [0.4] |

The leg spacing measured between the points of tangency of the bend to the legs shall not vary from the value (2R− specified tube OD) by more than 1 ⁄ 16 in. [1.5 mm] where R is the centerline bend radius.

The bent portion of the U-tube shall be substantially uniform in curvature and not exceed 6 1 ⁄ 16 in. [61.5 mm] ofthe normal centerline radius.

“The Ultimate Guide to ASTM A556 Seamless Steel Boiler Pipe: Properties, Applications, and Installation”

“Exploring the Benefits and Advantages of ASTM A556 Seamless Steel Boiler Pipe”

“Everything You Need to Know About ASTM A556 Seamless Steel Boiler Pipe: A Comprehensive Overview”

“Understanding the Importance of ASTM A556 Seamless Steel Boiler Pipe in Industrial Applications”

“ASTM A556 Seamless Steel Boiler Pipe: The Ideal Solution for High-Pressure and High-Temperature Environments”

- “Unveiling the Strength and Durability of ASTM A556 Seamless Steel Boiler Pipe”

- “Enhancing Boiler System Efficiency with ASTM A556 Seamless Steel Boiler Pipe”

- “Maximizing Performance and Longevity with ASTM A556 Seamless Steel Boiler Pipe”

- “ASTM A556 Seamless Steel Boiler Pipe: Ensuring Reliable and Safe Operations”

- “ASTM A556 Seamless Steel Boiler Pipe: Meeting Industry Standards for Quality and Performance”