ASTM A249 Stainless Steel Boiler Tube

June 22, 2024

SAE 4130 Seamless Steel Pipe

July 3, 202412Cr1MoV High Pressure Alloy Steel Boiler Pipe

The service temperature is 580 ℃, and the steel plate is required to have high high temperature endurance strength. The steel plate is delivered in the normalized and tempered state. 12Cr1MoVG alloy pipe is based on high-quality carbon structural steel, and one or several alloy elements are appropriately added to improve the mechanical properties, toughness and hardenability of the steel.

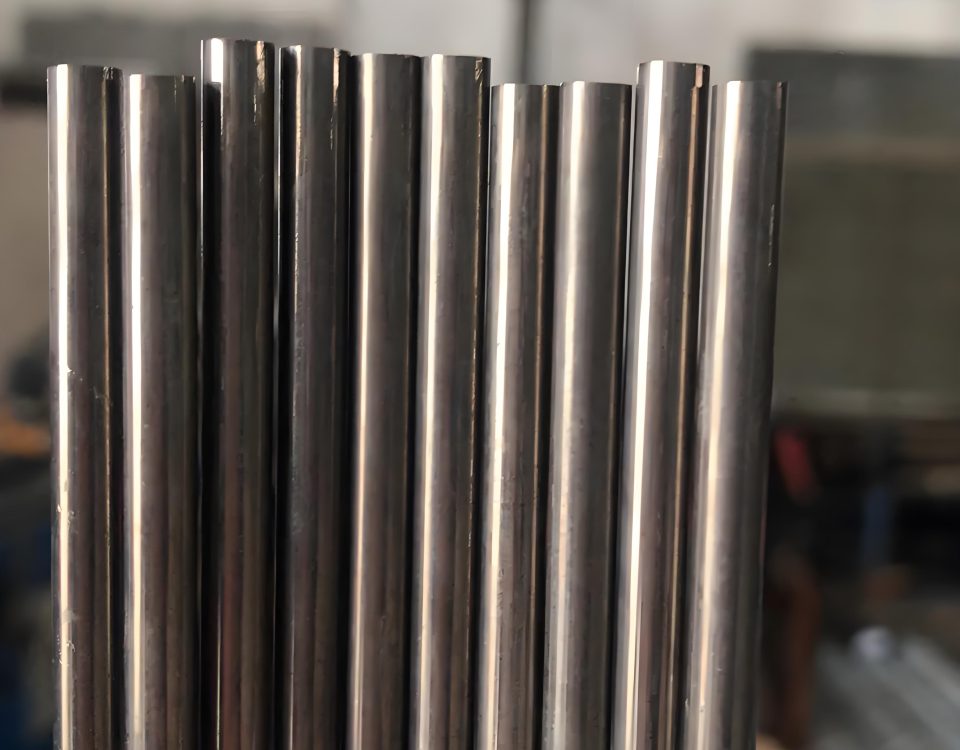

12Cr1MoV High Pressure Alloy Steel Boiler Pipe

Product Introduction

12Cr1MoV is a high-pressure alloy steel pipe widely used in power plants and industrial boilers. Known for its excellent mechanical properties and resistance to high temperatures and pressures, this alloy steel is ideal for demanding applications.

Characteristics of 12Cr1MoV Alloy Pipe

- High Temperature Resistance: Capable of operating efficiently under high temperatures.

- Corrosion Resistance: Offers significant resistance to oxidation and corrosion, especially in high-pressure environments.

- Mechanical Strength: Provides high tensile and yield strength, ensuring durability and reliability under stress.

12Cr1MoV Alloy Pipe Material

12Cr1MoV is a type of low alloy steel, incorporating chromium, molybdenum, and vanadium. These elements enhance its strength, durability, and ability to withstand high temperatures, making it suitable for high-pressure applications.

Application of 12Cr1MoV Alloy Pipe

- Power Plants: Used in the construction of high-pressure boilers and pressure vessels.

- Petrochemical Industry: Suitable for high-temperature, high-pressure pipelines.

- Boilers: Ideal for superheaters and reheaters in thermal power plants.

- Mechanical Engineering: Applied in various high-pressure, high-temperature components and equipment.

Process Flow of 12Cr1MoVG Alloy Pipe

- Raw Material Selection: High-quality alloy steel is selected for processing.

- Forming: Pipes are formed through hot rolling or cold drawing processes.

- Heat Treatment: Includes normalizing, quenching, and tempering to achieve the desired mechanical properties.

- Inspection: Conduct rigorous tests such as ultrasonic testing, hydrostatic testing, and dimensional inspections.

- Finishing: Surface treatment and final quality checks ensure compliance with standards.

The service temperature is 580 ℃, and the steel plate is required to have high high temperature endurance strength. The steel plate is delivered in the normalized and tempered state. 12Cr1MoVG alloy pipe is based on high-quality carbon structural steel, and one or several alloy elements are appropriately added to improve the mechanical properties, toughness and hardenability of the steel.

Chemical Compositions (%)

| Element | Composition (%) |

|---|---|

| C | 0.08 – 0.15 |

| Si | 0.17 – 0.37 |

| Mn | 0.40 – 0.70 |

| Cr | 0.90 – 1.20 |

| Mo | 0.25 – 0.35 |

| V | 0.15 – 0.30 |

| P | ≤ 0.030 |

| S | ≤ 0.030 |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 470 MPa |

| Yield Strength | ≥ 255 MPa |

| Elongation | ≥ 21% |

| Reduction of Area | ≥ 50% |

| Impact Toughness | ≥ 41 J at -20°C |

| Hardness | ≤ 179 HB |

Wall Thickness (W.T.) Tolerance

- Seamless Pipes: ±12.5% of the nominal wall thickness.

- Welded Pipes: ±10.0% of the nominal wall thickness.

|

W.T.(S) |

Tolerance of W.T. |

|

|

<3.5 |

+15%(+0.48mm min) |

|

|

-10%(+0.32mm min) |

||

|

3.5-20 |

+15%,-10% |

|

|

>20 |

D<219 |

±10% |

|

D≥219 |

+12.5%,-10% |

|

Inspection and Testing

To ensure the high quality and performance of 12Cr1MoV alloy pipes, a series of rigorous inspection and testing procedures are implemented throughout the production process:

- Visual Inspection: Preliminary examination for surface defects and overall appearance.

- Dimensional Inspection: Verification of pipe dimensions, including outer diameter, wall thickness, and length, to ensure compliance with specified tolerances.

- Non-Destructive Testing (NDT):

- Ultrasonic Testing (UT): Detects internal defects such as cracks and inclusions.

- Magnetic Particle Testing (MT): Identifies surface and near-surface discontinuities.

- Radiographic Testing (RT): Examines the internal structure for any anomalies.

- Hydrostatic Testing: Ensures the pipe can withstand specified pressure without leaking.

- Mechanical Testing:

- Tensile Test: Measures tensile strength, yield strength, and elongation.

- Hardness Test: Determines the hardness value to ensure the material meets specified requirements.

- Impact Test: Assesses toughness, particularly at low temperatures.

- Chemical Analysis: Confirms the chemical composition of the alloy to ensure it meets the required specifications.

Packaging and Delivery

Proper packaging and handling of 12Cr1MoV alloy pipes are crucial to prevent damage during transportation and storage:

- Packaging:

- Pipes are typically bundled and secured with steel strips.

- Ends are capped to prevent contamination.

- Protective coatings may be applied to prevent rust and corrosion.

- Marking:

- Each pipe is marked with relevant details such as grade, size, heat number, and manufacturer’s name.

- Documentation:

- Comprehensive documentation accompanies the shipment, including inspection and testing certificates, material test reports (MTR), and compliance certificates.

Advantages of 12Cr1MoV Alloy Pipe

- High Strength and Durability: Suitable for harsh environments due to its robust mechanical properties.

- Thermal Stability: Maintains performance under high temperatures, making it ideal for boilers and pressure vessels.

- Corrosion Resistance: Excellent resistance to oxidation and corrosion extends the service life of the pipes.

- Versatility: Used in various high-pressure and high-temperature applications across multiple industries.

12Cr1MoV high-pressure alloy steel boiler pipes are essential components in power generation and industrial applications. Their superior mechanical properties, high-temperature resistance, and corrosion resistance make them ideal for demanding environments. Through stringent manufacturing, inspection, and testing processes, these pipes ensure reliability and longevity in service.For more detailed specifications, technical support, or to place an order, please contact the manufacturer or refer to the relevant industry standards.