E235 CASING TUBING for UAE Client

October 13, 2021

Carbon Seamless Pipes for DURBAN Client

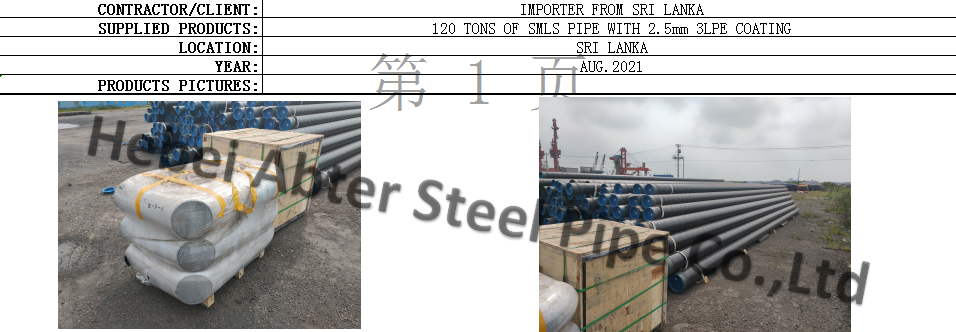

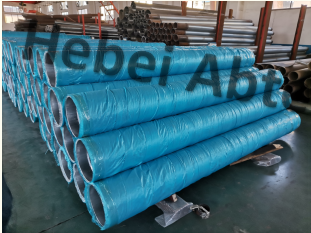

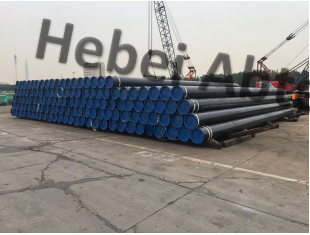

October 13, 20213LPE/2LPE coating, PE is the abbreviation for polyethylene.

The coating is made of hot-melt epoxy powder (FBE) as the bottom layer (2LPE epoxy powder without a bottom layer), vinyl copolymer adhesive (AD) as the middle layer, and high-density polyethylene (PE) as the surface layer The three-layer structure anti-corrosion coating. This structure mainly perfects the high adhesion, oxidation resistance, chemical corrosion resistance and excellent cathodic stripping resistance of FBE and the moisture resistance, aging resistance, insulation and mechanical damage resistance of high-density polyethylene/propylene. integrate. This kind of anti-corrosion layer has many advantages such as strong adhesion to the surface of the steel pipe, good insulation performance, resistance to mechanical shock, long service life, and low current density of cathodic protection. It is widely used in long-distance pipelines such as water, oil and gas.

The raw materials of 3LPE anticorrosion layer can be divided into two types: normal temperature type and high temperature type. The normal temperature operating temperature is 60⁰C, and the high temperature type operating temperature is 80⁰C. 3LPE/2LPE coating implements DIN30670, NF A49-710, CAN/CSA Z245.21, ISO DIS21809-1, GB/T23257, SY/T0413 and other standards.

Currently, vinyl copolymer adhesives are widely used. The functional groups of the polar part of the copolymer adhesive can react with the epoxy groups of the fusion-bonded epoxy powder coating to form hydrogen bonds or bonds. Make the middle layer and the bottom layer form a good bond; the non-polar ethylene part has a good affinity with the surface layer polyethylene, so the middle layer and the surface layer also have good bonding properties. The main function of the polyethylene surface layer is to play a mechanical protection and anti-corrosion effect, which is the same as the traditional two-layer structure polyethylene anti-corrosion layer.

How to repair 3LPE anticorrosive seamless steel pipe three-layer poly anticorrosive steel pipe: When defects are found on the E pipe, the radiation cross-linked poly repair patch should be used to repair the damage less than or equal to 30mm. When repairing, first remove the dirt on the damaged part, and woolen the polymer layer there. Then trim the polymer layer of the damaged part into a circle, and the edge should be poured into an obtuse angle. Fill the hole with the adhesive that matches the patch, and then attach the patch. The size of the patch should ensure that its margin is not less than 100mm from the edge of the hole in the polymer layer. When subsidizing, use a roller while heating or squeeze it by hand with heat-resistant gloves to exhaust the air until the adhesive around the patch is evenly overflowed. For damage larger than 30mm, first remove the dirt on the damaged part, roughen the polymer layer at that point, and trim the polymer layer at the damaged part into a round shape. The edges should be poured into an obtuse angle. Fill the hole with the adhesive matching the patch, and attach the patch. When defects are found on the anticorrosive three-layer PE pipe, the damage less than or equal to 30mm should be repaired with radiation cross-linked poly patch.