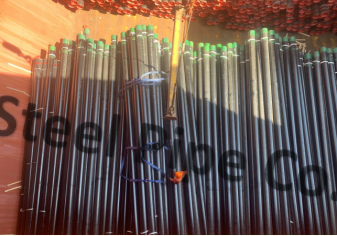

Drill Pipe for Mining

July 2, 2020

16Mo3 Alloy Tube for Durban Client

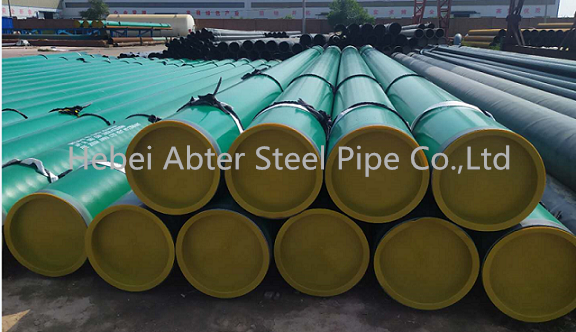

July 9, 20203PE, we also called 3LPE.It is used in transferring natural gas, crude oil and refined oil product over long distances. It also can be used in the urban fuel gas piping system, storage tanks, and groove piping system. 3PE’s main purpose is protecting pipes which used in electricity and communication industries and water piping systems.

Layers of 3PE coated steel pipe

Just as its name implies, 3PE coating including 3 Layers.

The first layer of 3PE coating:

Fusion bonded epoxy, which thickness is larger than 100μm. ( Thickness of FBE coated >100μm )

The second layer of 3PE coating:

Adhesive layer. It is binding epoxy and PE layers. ( Thickness of second layer: 170~250μm)

The third layer of 3PE coating:

PE layers. Thickness is from 2.5 mm to 3.7 mm. It is polyethylene which has advantages to anti-water, electrical resistance, and anti mechanical damage. It is a very important layer.

Characteristics of 3PE coated steel pipe :

- High tightness. It can save energy, reduce costs, protect the environment in long-term operation.

- Corrosion resistance is very strong. The construction side simply speed. Up to 30~50 years service life.

- With good resistance to corrosion and impact resistance, low water absorption. The PE ( less than 0.01% ) at low temperatures.

- High strength epoxy. PE absorbent and hot melt adhesive softness, etc. have high corrosion reliability.