The advantage of the ERW

July 13, 2021

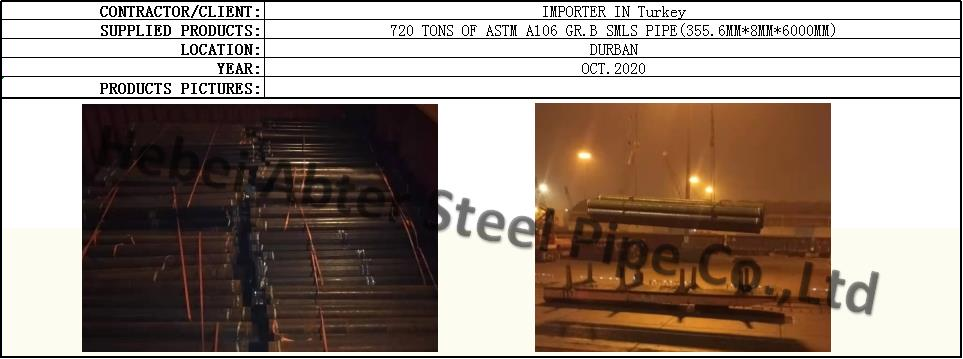

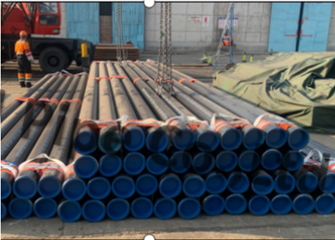

ASTM A106 GRB SMLS Pipe for South Africa Client

July 14, 2021ASTM A106gr.B seamless steel tube is a kind of low carbon steel widely used in petroleum, chemical, boiler and other industries.The material has good mechanical properties.A106gr.B tube is equivalent to Chinese steel 20#, in accordance with ASTM A106 high temperature seamless carbon steel nominal tube standard, class B.The limit service temperature of A106B is 425℃.

Seamless steel tube is hollow section, a large number of pipe, steel tube and round steel used to transport fluid, at the same time in the stage of flexural and torsional strength compared with solid steel, the weight is lighter, is a kind of economic section steel, widely used in the manufacture of structural and mechanical parts, such as oil drill pipe, automobile transmission shaft, bicycle frame and steel scaffolding construction.Seamless steel tubes are generally used to ensure strength and flattening tests.Hot-rolled steel tube is delivered in hot-rolled or heat-treated state;Cold rolled and delivered in heat treated condition.Hot rolling, as the name implies, the rolled piece temperature is high, so the deformation resistance is small, the deformation is large.Taking plate rolling as an example, the thickness of continuous casting billet is generally about 230mm, and after roughing and finishing, the final thickness is 1~20mm.At the same time, due to the small width to thickness ratio of steel plate, dimensional accuracy is relatively low, it is not easy to appear shape problems, mainly to control the crown.As for the structure requirements, the microstructure and mechanical properties of the strip are generally controlled by controlling the rolling and cooling, that is, the opening temperature, the finishing temperature and the crimping temperature of the strip.Not prone to shape problems, mainly to control the crown.As for the structure requirements, the microstructure and mechanical properties of the strip are generally controlled by controlling the rolling and cooling, that is, the opening temperature, the finishing temperature and the crimping temperature of the strip.Not prone to shape problems, mainly to control the crown.As for the structure requirements, the microstructure and mechanical properties of the strip are generally controlled by controlling the rolling and cooling, that is, the opening temperature, the finishing temperature and the crimping temperature of the strip.