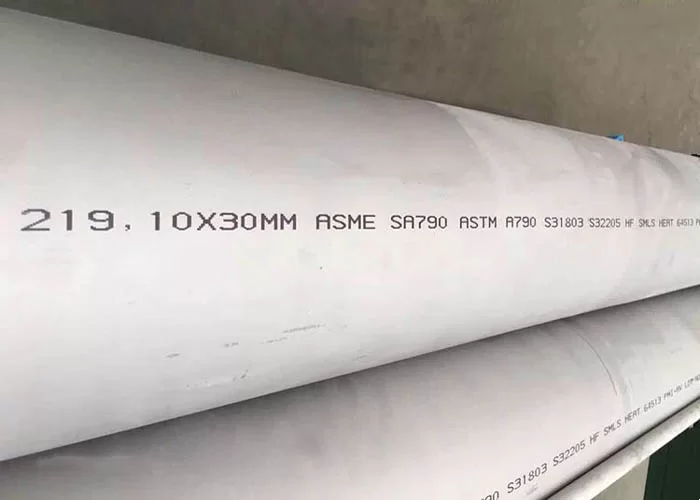

Duplex S32205 & UNS S31803 Stainless Steel Pipe

April 27, 2024

ASTM A554 Stainless Steel Pipe

May 14, 2024Duplex S31803 & Super Duplex S32750 Steel Pipe

Duplex-grade stainless steel alloys have ferritic/austenitic properties, giving these materials superior strength and excellent resistance to oxidation. While the duplex-grade family includes a wide range of specific formulations, duplex S31803 (2205) and super duplex S32750 (2507) stainless steel are two of the most common. These stainless steel products are extremely versatile, with many applications in the oil and gas, petrochemical, and chemical processing industries.

Duplex S31803 & Super Duplex S32750 Steel Pipe: A Comprehensive Overview

In the world of stainless steel pipes, Duplex S31803 and Super Duplex S32750 are two remarkable alloys that offer exceptional properties and performance. These duplex stainless steels are widely used in various industries due to their superior corrosion resistance, high strength, and excellent durability. In this article, we will delve into the characteristics, applications, and advantages of Duplex S31803 and Super Duplex S32750 steel pipes.

1. Duplex S31803 Steel Pipe:

Duplex S31803, also known as 2205 stainless steel, is a popular duplex alloy that combines the benefits of both ferritic and austenitic stainless steels. It is composed of approximately 22% chromium, 5-6% nickel, 3% molybdenum, and a small amount of nitrogen. The presence of these elements imparts excellent resistance to corrosion, especially in environments containing chlorides.

Advantages of Duplex S31803 Steel Pipe:

- Corrosion Resistance: Duplex S31803 steel pipe exhibits superior resistance to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. This makes it suitable for applications in marine environments, offshore oil and gas exploration, chemical processing, and more.

- High Strength: Duplex S31803 steel pipe offers higher strength compared to conventional austenitic stainless steels. This makes it an ideal choice for applications that require structural integrity and load-bearing capacity.

- Cost-Effectiveness: Duplex S31803 steel pipe provides a cost-effective solution due to its longer service life, reduced maintenance requirements, and lower lifecycle costs.

Applications of Duplex S31803 Steel Pipe:

- Oil and gas industry: Subsea pipelines, offshore platforms, and risers.

- Chemical and petrochemical industry: Process piping, heat exchangers, and storage tanks.

- Desalination plants: Seawater intake and brine outfall systems.

- Pulp and paper industry: Digesters, bleach washers, and evaporators.

- Food processing industry: Heat exchangers, storage tanks, and piping systems.

2. Super Duplex S32750 Steel Pipe:

Super Duplex S32750, also known as SAF 2507, is a highly alloyed duplex stainless steel that offers even higher corrosion resistance and mechanical properties compared to Duplex S31803. It contains approximately 25% chromium, 7% nickel, 4% molybdenum, and a small amount of nitrogen.

Advantages of Super Duplex S32750 Steel Pipe:

- Enhanced Corrosion Resistance: Super Duplex S32750 steel pipe provides exceptional resistance to corrosion in aggressive environments, including those with high chloride content. It is highly resistant to pitting, crevice corrosion, and general corrosion, making it suitable for demanding applications.

- High Strength and Toughness: Super Duplex S32750 steel pipe exhibits excellent mechanical properties, including high tensile strength and impact toughness. This allows it to withstand high-pressure and high-stress conditions.

- Wide Temperature Range: Super Duplex S32750 steel pipe can operate in a wide temperature range, from cryogenic temperatures up to 600°F (316°C), making it suitable for various applications across different industries.

Applications of Super Duplex S32750 Steel Pipe:

- Oil and gas industry: Subsea equipment, offshore platforms, and pipelines.

- Chemical and petrochemical industry: Heat exchangers, pressure vessels, and storage tanks.

- Desalination plants: Reverse osmosis systems, brine heaters, and evaporators.

- Power generation: Flue gas desulfurization systems and heat exchangers.

- Marine industry: Shipbuilding, seawater cooling systems, and offshore structures.

In conclusion, both Duplex S31803 and Super Duplex S32750 steel pipes offer exceptional properties and performance in terms of corrosion resistance, strength, and durability. Whether it’s for the oil and gas industry, chemical processing, desalination plants, or other demanding applications, these duplex stainless steel pipes provide reliable and cost-effective solutions. Consult with a trusted supplier or manufacturer to determine the best choice for your specific requirements.

Duplex Stainless Steel: UNS S31803

Duplex stainless steel UNS S31803 is a popular choice in industries where a combination of high strength and excellent corrosion resistance is required. It is composed of a balanced mixture of austenite and ferrite microstructures, which gives it its unique properties.

Chemical Composition

The chemical composition of duplex stainless steel UNS S31803 is as follows:

- Carbon (C): Maximum 0.030%

- Manganese (Mn): Maximum 2%

- Phosphorus (P): Maximum 0.030%

- Sulphur (S): Maximum 0.020%

- Silicon (Si): Maximum 1.00%

- Chromium (Cr): Minimum 21.0%, Maximum 23.0%

- Nickel (Ni): Minimum 4.5%, Maximum 6.5%

- Nitrogen (N): Minimum 0.08%, Maximum 0.20%

- Molybdenum (Mo): Minimum 2.5%, Maximum 3.5%

Mechanical Composition

The mechanical composition of duplex stainless steel UNS S31803 is as follows:

- Tensile Strength (Minimum): 90,000 psi

- Yield Strength (Minimum): 65,000 psi

- Elongation (Minimum): 25%

- Reduction of Area (Minimum): 50%

- Hardness (BHN): Maximum 290

Super Duplex Stainless Steel: UNS S32750

Super duplex stainless steel UNS S32750 is a higher grade of duplex stainless steel that offers even greater strength and corrosion resistance. It is widely used in industries such as oil and gas, chemical processing, and marine applications.

Chemical Composition

The chemical composition of super duplex stainless steel UNS S32750 is as follows:

- Carbon (C): Maximum 0.030%

- Manganese (Mn): Maximum 1.20%

- Phosphorus (P): Maximum 0.035%

- Sulphur (S): Maximum 0.020%

- Silicon (Si): Maximum 0.80%

- Chromium (Cr): Minimum 24.0%, Maximum 26.0%

- Nickel (Ni): Minimum 6.0%, Maximum 8.0%

- Nitrogen (N): Minimum 0.24%, Maximum 0.32%

- Molybdenum (Mo): Minimum 3.0%, Maximum 5.0%

- Copper (Cu): Maximum 0.50%

Mechanical Composition

The mechanical composition of super duplex stainless steel UNS S32750 is as follows:

- Tensile Strength (Less or Equal To 2″): 116,000 psi

- Tensile Strength (Greater Than 2″): 110,000 psi

- Yield Strength (Less or Equal To 2″): 80,000 psi

- Yield Strength (Greater Than 2″): 75,000 psi

- Elongation (Minimum): 15%

- Reduction of Area: Not specified

- Hardness (BHN): Maximum 310

Frequently Asked Questions (FAQ)

Q1: What is the difference between duplex and super duplex stainless steel?

A1: The main difference between duplex and super duplex stainless steel lies in their chemical composition. Super duplex stainless steel contains higher levels of chromium, nickel, and molybdenum, which contribute to its superior strength and corrosion resistance compared to duplex stainless steel.

Q2: What are the typical applications of duplex stainless steel?

A2: Duplex stainless steel is commonly used in industries such as oil and gas, chemical processing, pulp and paper, and marine applications. It is suitable for applications that require high strength, good weldability, and resistance to corrosion and stress corrosion cracking.

Q3: What are the advantages of super duplex stainless steel?

A3: Super duplex stainless steel offers several advantages, including exceptional strength, excellent corrosion resistance in aggressive environments, and high resistance to pitting and crevice corrosion. It is also highly resistant to stress corrosion cracking and has good weldability.

Q4: Can duplex and super duplex stainless steel be heat treated?

A4: Duplex and super duplex stainless steel can be heat treated to enhance their mechanical properties. However, it is important to carefully control the heat treatment process to avoid detrimental effects on the microstructure and corrosion resistance of the alloys.

Q5: What are the limitations of using duplex and super duplex stainless steel?

A5: While duplex and super duplex stainless steel offer many advantages, they also have some limitations. These alloys can be more expensive than other types of stainless steel, and their higher alloy content can make them more difficult to fabricate. Additionally, they may have reduced toughness at low temperatures compared to other stainless steel grades.

Conclusion

Duplex and super duplex stainless steel are highly versatile alloys that offer exceptional strength and corrosion resistance. Understanding their chemical and mechanical composition is crucial for selecting the right grade for specific applications. UNS S31803 and UNS S32750 are two popular grades that are widely used in various industries. By considering their composition and properties, engineers and designers can make informed decisions when choosing the appropriate stainless steel for their projects.