Benefits of Epoxy Pipe Liners for Corrosion Protection

December 8, 2024

A106/ASTM A53 GR.B SMLS Pipe

December 15, 2024

Carbon Steel Hollow Section: Square, Rectangular, and Circular Tubes

Introduction

Carbon steel hollow sections are versatile and widely used structural components in construction, engineering, and manufacturing. These hollow sections are available in three primary shapes: square, rectangular, and circular. They are known for their strength, durability, and adaptability, making them ideal for various applications such as building frameworks, bridges, machinery, and even furniture.

This article provides a comprehensive guide to carbon steel hollow sections, including their properties, manufacturing processes, applications, advantages, and detailed tables for dimensions and specifications. Whether you are an engineer, architect, or manufacturer, this guide will help you understand the importance of hollow sections in modern industries.

What Are Carbon Steel Hollow Sections?

Carbon steel hollow sections are tubular steel products with a hollow cross-section. They are made from carbon steel, a material composed primarily of iron and carbon, with trace amounts of other elements. The hollow design reduces weight while maintaining strength, making these sections efficient and cost-effective.

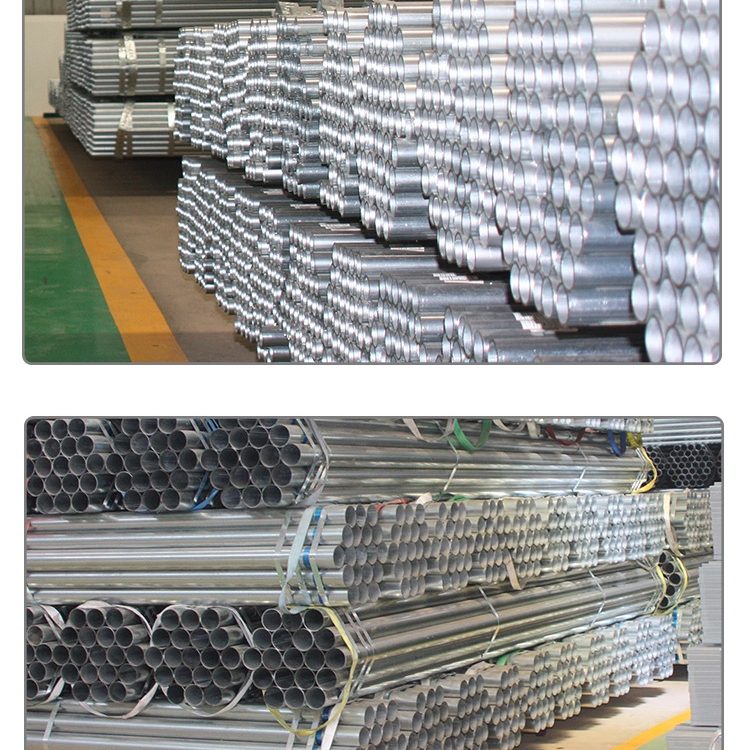

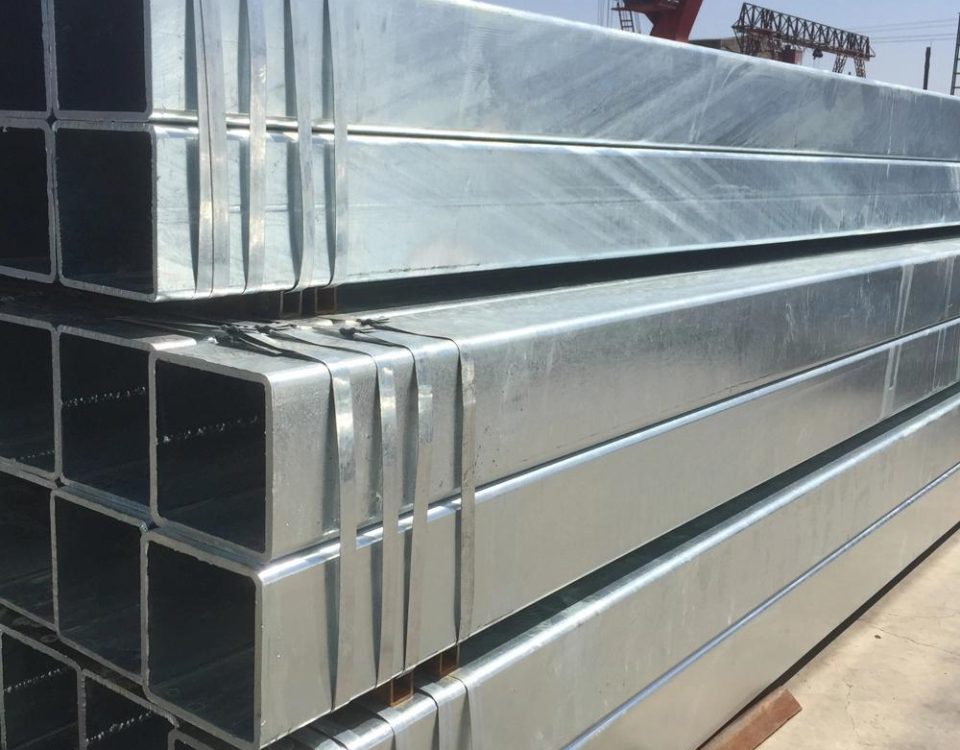

Types of Carbon Steel Hollow Sections

- Square Hollow Sections (SHS): Hollow tubes with a square cross-section.

- Rectangular Hollow Sections (RHS): Hollow tubes with a rectangular cross-section.

- Circular Hollow Sections (CHS): Hollow tubes with a circular cross-section, also known as pipes or tubes.

Properties of Carbon Steel Hollow Sections

Key Features

- High Strength-to-Weight Ratio: Provides excellent structural integrity while reducing weight.

- Versatility: Available in various shapes, sizes, and thicknesses for diverse applications.

- Durability: Resistant to deformation, cracking, and fatigue under heavy loads.

- Ease of Fabrication: Can be easily cut, welded, and shaped to meet specific requirements.

- Cost-Effective: Offers a balance of affordability and performance.

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 400–550 MPa |

| Yield Strength | 250–350 MPa |

| Elongation | 20–25% |

| Density | 7.85 g/cm³ |

| Modulus of Elasticity | 200 GPa |

| Thermal Conductivity | 50–60 W/m·K |

Manufacturing Process of Hollow Sections

The production of carbon steel hollow sections involves several steps to ensure high quality and precision:

1. Material Preparation

- Carbon steel sheets or coils are selected based on the desired grade and thickness.

- The material is cleaned and prepared for forming.

2. Forming

- Square and Rectangular Sections: The steel sheet is rolled into a circular shape and then formed into square or rectangular profiles using rollers.

- Circular Sections: The steel sheet is rolled into a circular shape and welded along the seam.

3. Welding

- The edges of the steel sheet are welded together using high-frequency induction welding (HFIW) or submerged arc welding (SAW).

- The weld is inspected for defects to ensure structural integrity.

4. Sizing and Straightening

- The hollow section is passed through sizing rollers to achieve precise dimensions and straightness.

5. Cutting and Finishing

- The hollow section is cut to the required length and inspected for quality.

- Surface treatments, such as galvanization or painting, may be applied for corrosion resistance.

Applications of Carbon Steel Hollow Sections

Carbon steel hollow sections are used in a wide range of industries due to their versatility and strength. Common applications include:

1. Construction

- Structural Frameworks: Used in buildings, bridges, and industrial structures for load-bearing purposes.

- Columns and Beams: Provide support and stability in construction projects.

- Fencing and Gates: Used for their aesthetic appeal and durability.

2. Engineering and Manufacturing

- Machinery Components: Used in the fabrication of machine frames, supports, and parts.

- Automotive Industry: Used in chassis, roll cages, and exhaust systems.

- Furniture: Used in the production of tables, chairs, and shelving units.

3. Transportation

- Railways: Used in train carriages and railway infrastructure.

- Shipbuilding: Used in ship structures and pipelines.

4. Energy Sector

- Oil and Gas Pipelines: Used for transporting fluids and gases.

- Renewable Energy: Used in wind turbine towers and solar panel frames.

Advantages of Carbon Steel Hollow Sections

- Structural Efficiency: High strength-to-weight ratio reduces material usage and costs.

- Versatility: Available in various shapes and sizes for diverse applications.

- Ease of Fabrication: Can be easily welded, cut, and shaped.

- Durability: Resistant to wear, deformation, and environmental factors.

- Aesthetic Appeal: Provides clean and modern designs for architectural applications.

Dimensions and Specifications of Carbon Steel Hollow Sections

1. Square Hollow Sections (SHS)

| Size (mm) | Wall Thickness (mm) | Weight (kg/m) | Cross-Sectional Area (cm²) |

|---|---|---|---|

| 20 x 20 | 1.6 | 0.87 | 1.11 |

| 40 x 40 | 2.0 | 2.37 | 3.02 |

| 60 x 60 | 3.0 | 5.43 | 6.92 |

| 100 x 100 | 5.0 | 17.96 | 22.89 |

| 150 x 150 | 6.0 | 32.85 | 41.86 |

2. Rectangular Hollow Sections (RHS)

| Size (mm) | Wall Thickness (mm) | Weight (kg/m) | Cross-Sectional Area (cm²) |

|---|---|---|---|

| 50 x 25 | 2.0 | 2.45 | 3.12 |

| 100 x 50 | 3.0 | 6.85 | 8.73 |

| 150 x 100 | 4.0 | 13.16 | 16.76 |

| 200 x 100 | 5.0 | 20.91 | 26.65 |

| 300 x 200 | 6.0 | 42.85 | 54.58 |

3. Circular Hollow Sections (CHS)

| Diameter (mm) | Wall Thickness (mm) | Weight (kg/m) | Cross-Sectional Area (cm²) |

|---|---|---|---|

| 21.3 | 2.0 | 1.29 | 1.64 |

| 48.3 | 3.2 | 3.56 | 4.54 |

| 88.9 | 4.0 | 8.38 | 10.68 |

| 168.3 | 5.0 | 20.11 | 25.62 |

| 273.0 | 6.0 | 40.48 | 51.55 |

Comparison of SHS, RHS, and CHS

| Feature | Square (SHS) | Rectangular (RHS) | Circular (CHS) |

|---|---|---|---|

| Shape | Square | Rectangular | Circular |

| Load Distribution | Uniform | Better for flat surfaces | Ideal for radial loads |

| Applications | Columns, beams | Frames, structures | Pipelines, fluid transport |

| Aesthetic Appeal | Modern and clean | Sleek and versatile | Traditional and functional |

| Ease of Fabrication | Easy to weld and cut | Easy to weld and cut | Requires specialized tools |

Maintenance and Corrosion Protection

To ensure the longevity of carbon steel hollow sections, proper maintenance and corrosion protection are essential:

1. Protective Coatings

- Galvanization: Adds a zinc coating to prevent rust.

- Painting: Provides a protective barrier against moisture and chemicals.

2. Regular Inspection

- Check for signs of rust, deformation, or damage.

- Replace or repair damaged sections promptly.

3. Cathodic Protection

- Use sacrificial anodes or impressed current systems to prevent corrosion in buried or submerged sections.

Due to USD/RMB exchanging rate has been increasing, here we specially give you most reasonable price of Hollow Section The details is as below.

| Specifications | L X W | W.T | Unit Length |

QTY | FOB Price | ||

| Product | Standard & Material | mm | mm | mm | m | pcs | USD/TON |

| RHS | EN10219 S235JR | 150 | 100 | 6 | 6 | 100 | $650.00 |

| RHS | EN10219 S235JR | 200 | 100 | 8 | 6 | 150 | $650.00 |

| RHS | EN10219 S235JR | 300 | 200 | 8 | 6 | 100 | $675.00 |

| RHS | EN10219 S235JR | 200 | 150 | 8 | 6 | 200 | $650.00 |

| RHS | EN10219 S235JR | 400 | 200 | 10 | 6 | 250 | $675.00 |

| SHS | EN10219 S235JR | 200 | 200 | 12.5 | 6 | 120 | $650.00 |

| SHS | EN10219 S235JR | 100 | 100 | 6 | 6 | 175 | $650.00 |

| SHS | EN10219 S235JR | 200 | 200 | 8 | 6 | 115 | $650.00 |

Conclusion

Carbon steel hollow sections—whether square, rectangular, or circular—are indispensable in modern construction and engineering. Their strength, versatility, and cost-effectiveness make them ideal for a wide range of applications, from structural frameworks to machinery and pipelines. By understanding their properties, dimensions, and applications, you can select the right hollow section for your project and ensure its success.

FAQ

1. What are the main types of carbon steel hollow sections?

The main types are square hollow sections (SHS), rectangular hollow sections (RHS), and circular hollow sections (CHS).

2. What are the advantages of using hollow sections in construction?

Hollow sections offer a high strength-to-weight ratio, versatility, durability, and aesthetic appeal, making them ideal for structural and architectural applications.

3. How are carbon steel hollow sections manufactured?

They are made by rolling steel sheets into the desired shape (square, rectangular, or circular) and welding the edges together.

4. What is the difference between SHS, RHS, and CHS?

- SHS: Square cross-section, ideal for columns and beams.

- RHS: Rectangular cross-section, suitable for frames and flat surfaces.

- CHS: Circular cross-section, used for pipelines and fluid transport.

5. How can corrosion in hollow sections be prevented?

Corrosion can be prevented using protective coatings (galvanization, painting), cathodic protection, and regular maintenance.