EN10297-1 34CrMo4 Steel Pipe for Gas Cylinder

January 31, 2024

The Benefits of AWWA C210 Liquid Epoxy Coating for Pipeline Protection

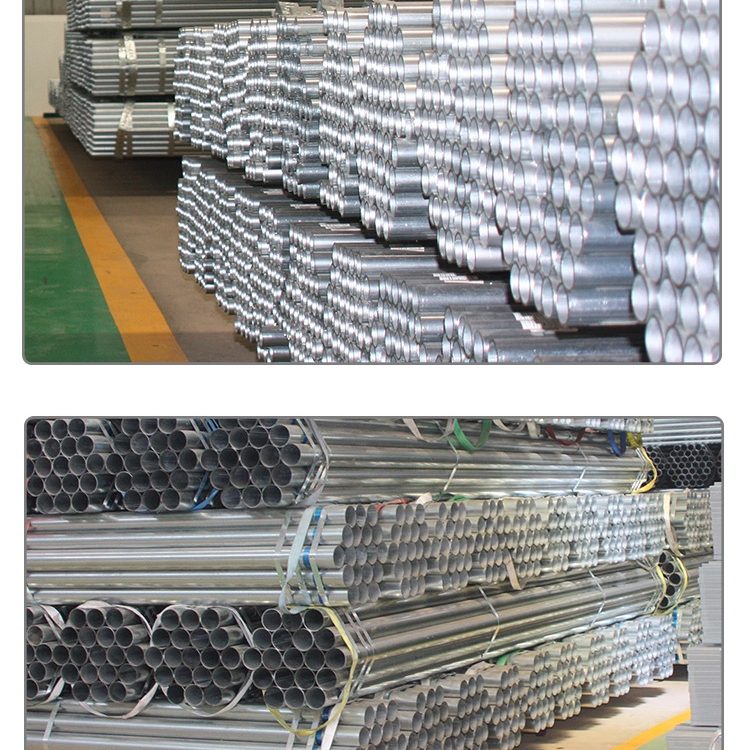

February 12, 2024STK400 STK500 Pre Galvanized Steel Pipe: The Ideal Choice for Construction Scaffold Galvanized Pipe

In the world of construction, safety and durability are of utmost importance. One crucial component that plays a significant role in ensuring the stability and strength of scaffolding structures is the galvanized steel pipe. Among the various options available, the STK400 and STK500 pre-galvanized steel pipes have gained immense popularity due to their exceptional qualities and suitability for construction scaffold applications. In this article, we will delve into the features, benefits, and applications of these pre-galvanized steel pipes.

What is Pre-Galvanized Steel Pipe?

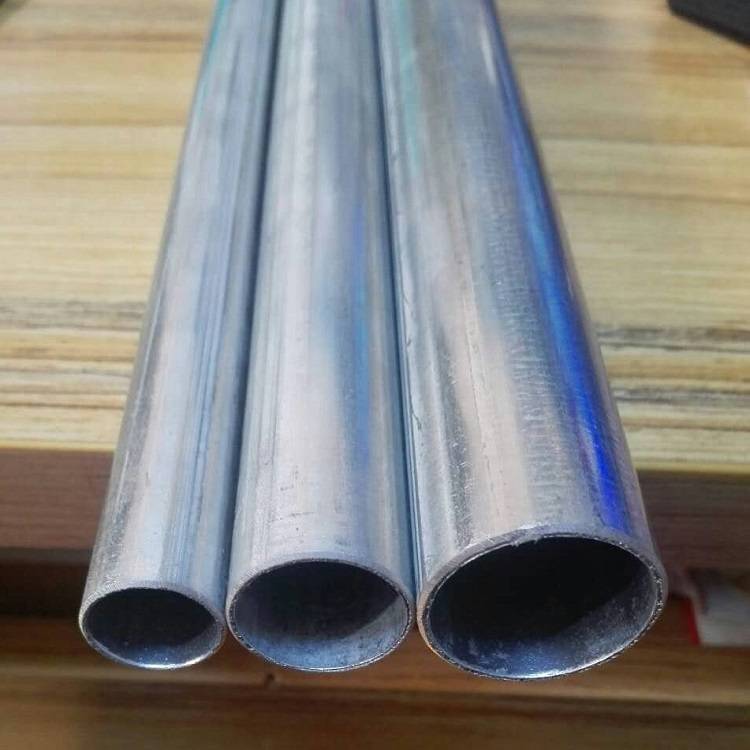

Pre-galvanized steel pipe refers to a type of steel pipe that has undergone a galvanization process before being formed into its final shape. Galvanization involves coating the steel pipe with a protective layer of zinc, which provides excellent corrosion resistance and enhances its longevity. The pre-galvanization process involves immersing the steel pipe in a bath of molten zinc, ensuring a uniform coating on both the inside and outside surfaces.

Features and Benefits of STK400 and STK500 Pre-Galvanized Steel Pipe

- Corrosion Resistance: The zinc coating on STK400 and STK500 pre-galvanized steel pipes acts as a barrier against corrosive elements, such as moisture and chemicals. This corrosion resistance ensures that the scaffolding structures remain intact and safe for prolonged periods, even in harsh environments.

- Durability: The combination of high-quality steel and the protective zinc coating makes STK400 and STK500 pre-galvanized steel pipes highly durable. They can withstand heavy loads, impacts, and other external forces commonly encountered in construction sites.

- Cost-Effective: Pre-galvanized steel pipes offer a cost-effective solution for construction scaffolding. The galvanization process enhances the longevity of the pipes, reducing the need for frequent replacements and maintenance. This cost-saving aspect makes them an attractive choice for construction companies.

- Easy Installation: STK400 and STK500 pre-galvanized steel pipes are lightweight and easy to handle, making them convenient for installation in scaffolding structures. Their standardized sizes and dimensions ensure compatibility with various scaffolding systems.

- Versatility: These pre-galvanized steel pipes are versatile and can be used in a wide range of construction applications, including scaffolding, handrails, fencing, and structural support. Their adaptability makes them a preferred choice for contractors and builders.

- Aesthetic Appeal: The silver-gray appearance of pre-galvanized steel pipes adds an aesthetic appeal to scaffolding structures, making them visually pleasing. This aspect is particularly important in projects where the scaffolding is visible and needs to blend seamlessly with the surrounding environment.

Applications of STK400 and STK500 Pre-Galvanized Steel Pipe

STK400 and STK500 pre-galvanized steel pipes find extensive use in construction scaffold applications. Some common applications include:

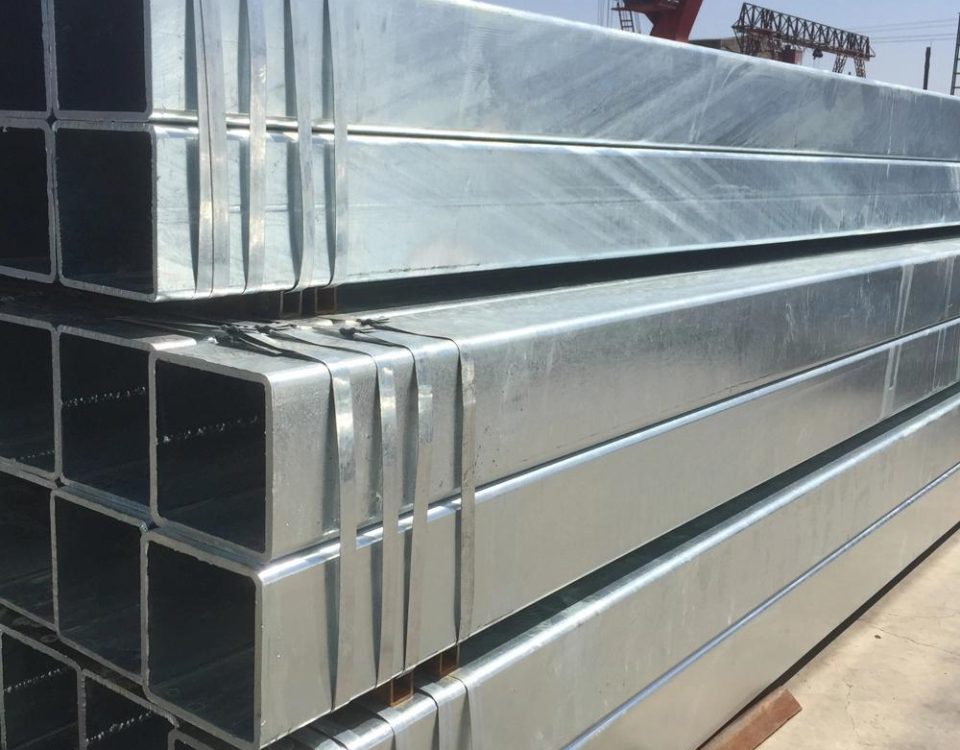

- Scaffolding Structures: Pre-galvanized steel pipes are widely used in the construction of scaffolding systems, providing a safe and stable platform for workers to perform tasks at elevated heights. The corrosion resistance and durability of these pipes ensure the long-term integrity of the scaffolding structures.

- Handrails and Guardrails: The high strength and corrosion resistance of STK400 and STK500 pre-galvanized steel pipes make them suitable for handrails and guardrails in construction sites, industrial facilities, and public spaces. These pipes provide essential safety features while maintaining an attractive appearance.

- Fencing: Pre-galvanized steel pipes are commonly used in fencing applications, providing a sturdy and secure boundary for construction sites, residential areas, and commercial properties. The corrosion resistance of these pipes ensures that the fencing remains intact and visually appealing for an extended period.

- Structural Support: STK400 and STK500 pre-galvanized steel pipes can be used as structural support components in various construction projects. They provide stability and strength to buildings, bridges, and other structures, ensuring their longevity and safety.

Conclusion

STK400 and STK500 pre-galvanized steel pipes are the ideal choice for construction scaffold galvanized pipe applications. Their corrosion resistance, durability, cost-effectiveness, and versatility make them highly sought after in the construction industry. Whether it’s for scaffolding structures, handrails, fencing, or structural support, these pre-galvanized steel pipes provide the necessary strength, safety, and aesthetic appeal. By opting for STK400 and STK500 pre-galvanized steel pipes, construction companies can ensure the longevity and reliability of their scaffolding systems, contributing to a safer and more efficient work environment.

FAQ – STK400 STK500 Pre Galvanized Steel Pipe

1. What are the available sizes and lengths of STK400 and STK500 pre-galvanized steel pipes?

STK400 and STK500 pre-galvanized steel pipes are available in a range of sizes, with an outer diameter (OD) ranging from 1/2″ to 1 1/2″. The length of the pipes can be customized according to your requirements, with a maximum length of 12 meters (L < 12m).

2. What is the quality standard for STK400 and STK500 pre-galvanized steel pipes?

The quality standard for these pre-galvanized steel pipes is JIS G3444. This standard ensures that the pipes meet the necessary specifications and performance requirements for their intended applications.

3. What surface treatments are available for STK400 and STK500 pre-galvanized steel pipes?

STK400 and STK500 pre-galvanized steel pipes can be treated with various surface coatings, including galvanized, oiled, painted, or left bare. The choice of surface treatment depends on the specific requirements of your project.

4. What are the options for end treatment of STK400 and STK500 pre-galvanized steel pipes?

The end treatment options for these pre-galvanized steel pipes include plain or threaded ends. Each pipe is equipped with one end plastic cap and one end coupling, ensuring secure and convenient installation.

5. What tests are conducted on STK400 and STK500 pre-galvanized steel pipes?

STK400 and STK500 pre-galvanized steel pipes undergo several tests to ensure their quality and adherence to standards. These tests include chemical component analysis, mechanical properties testing, technical properties evaluation, and exterior size inspection. These tests guarantee the reliability and performance of the pipes in various applications.

6. What are the applications of STK400 and STK500 pre-galvanized steel pipes?

STK400 and STK500 pre-galvanized steel pipes have a wide range of applications. They are commonly used in structural projects, water systems, gas pipelines, and furniture making. Their versatility allows them to be utilized in various industries and construction projects.

7. What are the accepted payment terms for purchasing STK400 and STK500 pre-galvanized steel pipes?

The accepted payment terms for these pre-galvanized steel pipes include T/T (bank transfer), L/C (letter of credit), and Western Union. These payment options provide flexibility and convenience for buyers.

8. How are STK400 and STK500 pre-galvanized steel pipes packaged for shipping?

STK400 and STK500 pre-galvanized steel pipes are typically packaged in bundles or wrapped with water-proof PVC cloth. This packaging ensures the protection and safe transportation of the pipes to their destination.

9. What are the shipping options for STK400 and STK500 pre-galvanized steel pipes?

The shipping options for these pre-galvanized steel pipes include bulk shipments or loading in containers. The choice of shipping method depends on the quantity and destination of the pipes.

10. What are the chemical analysis and mechanical properties of STK400 and STK500 pre-galvanized steel pipes?

The chemical composition and mechanical properties of these pre-galvanized steel pipes are specified in the following tables:

Table 1. Chemical Composition (Unit: %)

| Symbol of Grade | C | Si | Mn | P | S |

|---|---|---|---|---|---|

| STK290 | – | – | – | 0.050 max. | 0.050 max. |

| STK400 | 0.25 max. | – | – | 0.040 max. | 0.040 max. |

| STK490 | 0.18 max. | 0.55 max. | 1.65 max. | 0.035 max. | 0.035 max. |

| STK500 | 0.24 max. | 0.35 max. | 0.30 to 1.30 | 0.040 max. | 0.040 max. |

| STK540 | 0.23 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. |

Table 2. Mechanical Properties

| Symbol of Grade | Tensile Strength (N/mm²) | Yield Point of Proof Stress (N/mm²) | Tensile Strength in Weld Zone (N/mm²) | Flattening | Bendability |

|---|---|---|---|---|---|

| STK290 | 290 min. | – | 290 min. | 2/3 D | 90° |

| STK400 | 400 min. | 235 min. | 400 min. | 2/3 D | # STK400 STK500 Pre-Galvanized Steel Pipes: A Comprehensive Guide |

Introduction

Pre-galvanized steel pipes are widely used in various industries and construction projects due to their durability, versatility, and cost-effectiveness. In this comprehensive guide, we will explore the key features, applications, and specifications of STK400 and STK500 pre-galvanized steel pipes. We will also delve into the chemical composition, mechanical properties, and various aspects related to these pipes. So, let’s dive in!

Size and Length

STK400 and STK500 pre-galvanized steel pipes are available in a range of sizes, with an outer diameter (OD) ranging from 1/2″ to 1 1/2″. The length of the pipes can be customized according to your requirements, with a maximum length of 12 meters (L < 12m). This flexibility in size and length ensures that these pipes can be tailored to fit specific project needs.

Quality Standard

The quality standard for STK400 and STK500 pre-galvanized steel pipes is JIS G3444. This standard ensures that the pipes meet the necessary specifications and performance requirements for their intended applications. Compliance with this standard guarantees the high quality and reliability of the pipes.

Surface Treatment

STK400 and STK500 pre-galvanized steel pipes can be treated with various surface coatings to enhance their durability and corrosion resistance. The available surface treatments include galvanized, oiled, painted, or leaving the pipes bare. The choice of surface treatment depends on the specific requirements of your project and the environmental conditions in which the pipes will be used.

End Treatment

To facilitate easy installation and connection, STK400 and STK500 pre-galvanized steel pipes are available with different end treatments. The options include plain ends or threaded ends. Each pipe is equipped with one end plastic cap and one end coupling, ensuring secure and convenient installation.

Testing and Inspection

To ensure the quality and performance of STK400 and STK500 pre-galvanized steel pipes, they undergo rigorous testing and inspection processes. These include:

- Chemical Component Analysis: This test analyzes the chemical composition of the pipes to ensure they meet the specified requirements. The chemical composition is crucial for determining the pipes’ mechanical properties and overall performance.

- Mechanical Properties Testing: The mechanical properties of the pipes, such as tensile strength and yield point of proof stress, are evaluated to ensure they meet the necessary standards. This testing ensures that the pipes can withstand the intended loads and stresses.

- Technical Properties Evaluation: The technical properties of the pipes, including dimensional accuracy, wall thickness, and surface finish, are carefully evaluated to ensure they meet the required specifications. This evaluation guarantees that the pipes are suitable for their intended applications.

- Exterior Size Inspection: The exterior dimensions of the pipes are inspected to ensure they conform to the specified requirements. This inspection ensures that the pipes can be easily connected and integrated into the overall system.

Applications

STK400 and STK500 pre-galvanized steel pipes find extensive applications in various industries and construction projects. Some common applications include:

- Structural Projects: These pipes are widely used in structural projects such as building frameworks, scaffolding, and support structures. Their high strength and durability make them ideal for withstanding heavy loads and providing structural stability.

- Water Systems: Pre-galvanized steel pipes are commonly used in water supply systems, including plumbing, irrigation, and water distribution networks. Their corrosion resistance and leak-proof properties make them suitable for transporting water safely and efficiently.

- Gas Pipelines: These pipes are also utilized in gas pipelines for the transportation of natural gas, propane, and other gases. Their ability to withstand high pressure and their resistance to corrosion make them a reliable choice for gas transmission.

- Furniture Making: Pre-galvanized steel pipes are used in the manufacturing of furniture, including chairs, tables, and shelves. Their strength, versatility, and aesthetic appeal make them an excellent choice for creating durable and stylish furniture pieces.

Payment Terms

When purchasing STK400 and STK500 pre-galvanized steel pipes, various payment terms are accepted to provide flexibility and convenience. The accepted payment terms include T/T (bank transfer), L/C (letter of credit), and Western Union. These options allow buyers to choose the most suitable payment method for their specific circumstances.

Packaging and Shipping

STK400 and STK500 pre-galvanized steel pipes are carefully packaged to ensure their protection and safe transportation. The pipes are typically bundled together or wrapped with water-proof PVC cloth. This packaging prevents damage during transit and ensures that the pipes arrive in optimal condition.

For shipping, two options are available: bulk shipments or loading in containers. The choice of shipping method depends on the quantity of pipes and the destination. Bulk shipments are suitable for large orders, while container loading provides added protection