ASTM A234 WP11 Chemical composition and mechanical properties

November 28, 2024

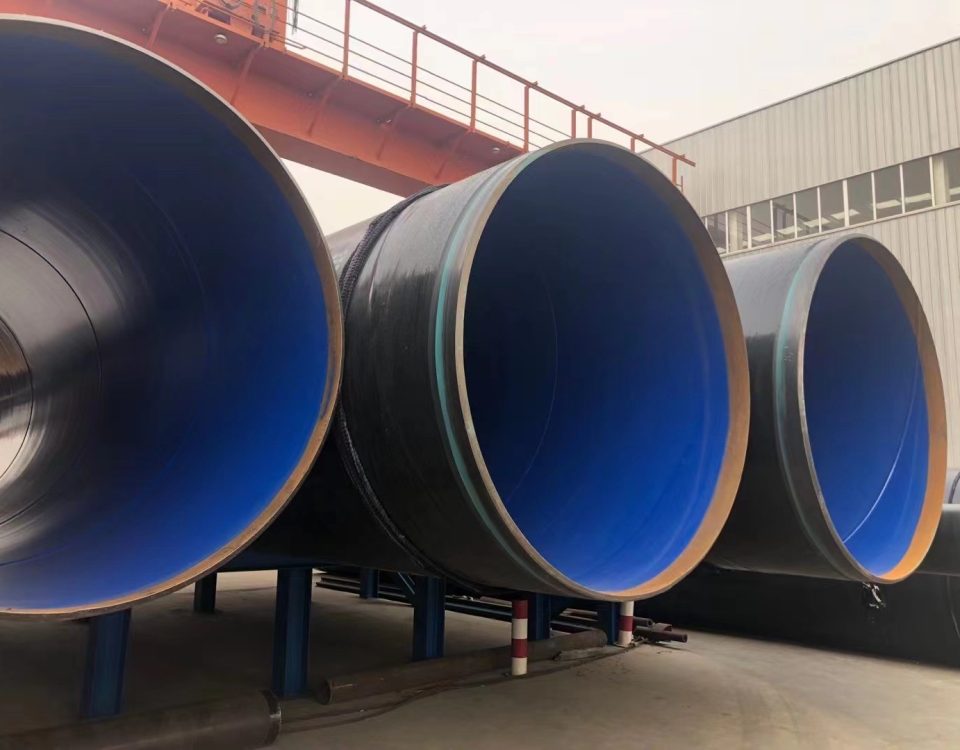

Benefits of Epoxy Pipe Liners for Corrosion Protection

December 8, 2024Validation of Theoretical Load-Carrying Capacity of Steel Pipe Piles

Introduction

Steel pipe piles are widely used in foundation engineering due to their high load-carrying capacity, durability, and versatility. These piles are often employed in projects requiring deep foundations, such as bridges, high-rise buildings, marine structures, and offshore platforms. The load-carrying capacity of a steel pipe pile is a critical parameter in ensuring the stability and safety of the structure it supports.

The theoretical load-carrying capacity of steel pipe piles is typically estimated using geotechnical and structural engineering principles. However, it is essential to validate these theoretical predictions through field tests, laboratory experiments, or numerical simulations to ensure their accuracy and reliability under real-world conditions.

This article provides a detailed overview of the methods used to validate the theoretical load-carrying capacity of steel pipe piles, including the key factors influencing their performance, the theoretical approaches used for capacity estimation, and the techniques for validation.

Table of Contents

- Understanding Steel Pipe Piles

- Theoretical Load-Carrying Capacity of Steel Pipe Piles

- Factors Influencing Load-Carrying Capacity

- Methods for Validation of Theoretical Capacity

- Static Load Testing

- Dynamic Load Testing

- Numerical Modeling

- Empirical Correlations

- Case Studies and Applications

- Challenges in Validation

- Frequently Asked Questions (FAQ)

- Conclusion

Understanding Steel Pipe Piles {#understanding-steel-pipe-piles}

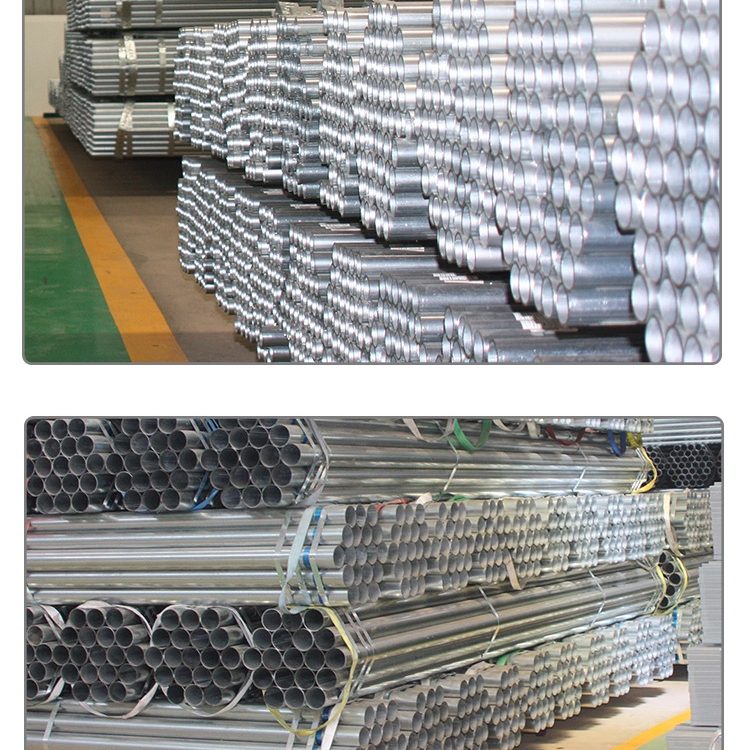

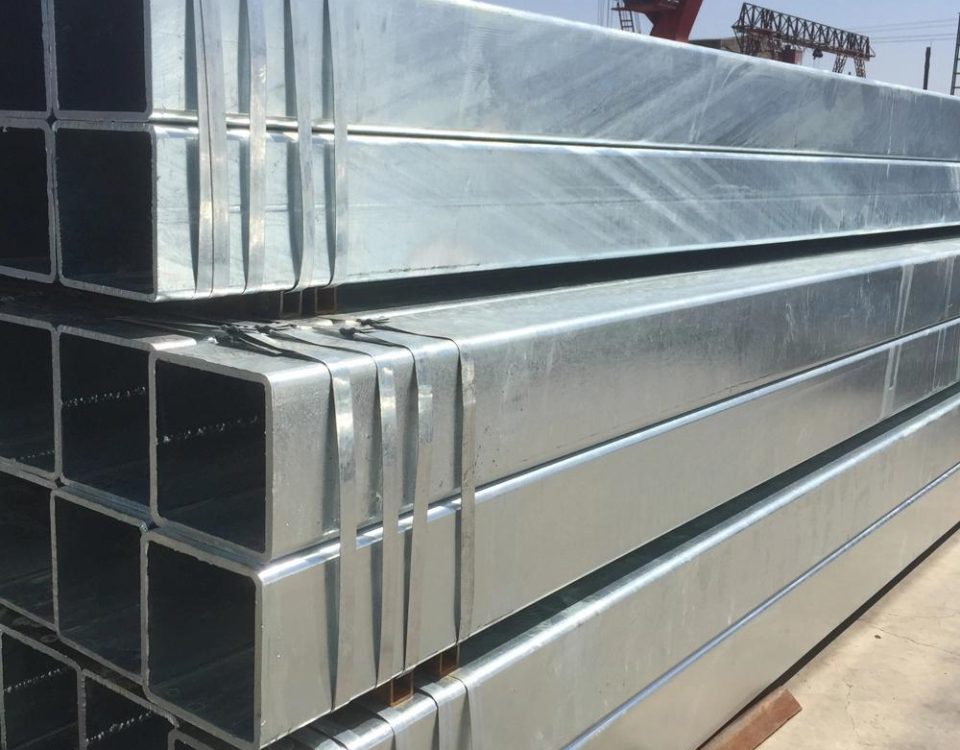

Steel pipe piles are cylindrical steel tubes used as deep foundation elements to transfer structural loads to deeper, more stable soil or rock layers. They are driven into the ground using pile-driving equipment or installed through drilling and grouting.

Key Characteristics:

- Hollow Structure: Steel pipe piles are hollow, which reduces their weight and allows for easy handling and transportation.

- High Strength: Made of high-grade steel, these piles have excellent compressive and tensile strength.

- Versatility: They can be used in various soil conditions, including soft clay, loose sand, and dense gravel.

- Customizable Dimensions: Steel pipe piles come in various diameters, lengths, and wall thicknesses to suit project-specific requirements.

Theoretical Load-Carrying Capacity of Steel Pipe Piles {#theoretical-load-carrying-capacity-of-steel-pipe-piles}

The theoretical load-carrying capacity of a steel pipe pile is determined by considering both its geotechnical capacity and structural capacity.

1. Geotechnical Capacity

The geotechnical capacity is the pile’s ability to resist loads through interaction with the surrounding soil. It consists of:

- End Bearing Capacity: The resistance offered by the soil or rock at the pile tip.

- Shaft Friction: The resistance generated along the pile’s surface due to friction with the surrounding soil.

The geotechnical capacity is calculated using soil parameters such as:

- Soil shear strength

- Soil density

- Friction angle

- Cohesion

2. Structural Capacity

The structural capacity is the pile’s ability to withstand the applied loads without structural failure. It is determined by the pile material’s:

- Yield strength

- Elastic modulus

- Cross-sectional area

The structural capacity is calculated using standard engineering formulas, such as:

Axial Load Capacity:

P=As⋅fyP = A_s \cdot f_y

Where:

- PP = Axial load capacity

- AsA_s = Cross-sectional area of the pile

- fyf_y = Yield strength of the steel

Factors Influencing Load-Carrying Capacity {#factors-influencing-load-carrying-capacity}

The load-carrying capacity of steel pipe piles is influenced by several factors, including:

1. Soil Conditions

- Soil Type: Cohesive soils (e.g., clay) and non-cohesive soils (e.g., sand) interact differently with the pile.

- Soil Strength: Higher soil strength increases the pile’s geotechnical capacity.

- Groundwater Table: High groundwater levels can reduce shaft friction and end bearing capacity.

2. Pile Dimensions

- Diameter: Larger diameters increase end bearing capacity.

- Length: Longer piles engage deeper soil layers with higher strength.

- Wall Thickness: Thicker walls enhance structural capacity.

3. Installation Method

- Driven Piles: Driving compacts the surrounding soil, increasing shaft friction.

- Drilled Piles: Drilling may disturb the soil, reducing shaft friction.

4. Load Type

- Axial Loads: Vertical loads applied along the pile’s axis.

- Lateral Loads: Horizontal loads due to wind, waves, or seismic activity.

- Dynamic Loads: Time-varying loads, such as those from machinery or traffic.

Methods for Validation of Theoretical Capacity {#methods-for-validation-of-theoretical-capacity}

Validating the theoretical load-carrying capacity of steel pipe piles involves comparing theoretical predictions with actual performance data obtained through testing or modeling. Common validation methods include:

1. Static Load Testing {#static-load-testing}

Static load testing is the most reliable method for validating pile capacity. It involves applying a gradually increasing load to the pile and measuring its settlement.

Procedure:

- Install the pile to the required depth.

- Apply a vertical load using a hydraulic jack.

- Measure the pile’s settlement at each load increment.

Advantages:

- Provides accurate data on pile behavior under static loads.

- Directly measures ultimate load capacity.

Limitations:

- Expensive and time-consuming.

- Requires heavy equipment and a reaction system.

2. Dynamic Load Testing {#dynamic-load-testing}

Dynamic load testing involves striking the pile with a hammer and measuring the resulting forces and displacements using sensors.

Procedure:

- Attach strain gauges and accelerometers to the pile.

- Strike the pile with a hammer.

- Analyze the data using wave equation analysis.

Advantages:

- Faster and more cost-effective than static load testing.

- Provides information on both geotechnical and structural capacity.

Limitations:

- Requires specialized equipment and expertise.

- Results may need to be correlated with static load test data.

3. Numerical Modeling {#numerical-modeling}

Numerical modeling uses computer simulations to predict pile behavior under various loading conditions.

Tools:

- Finite Element Analysis (FEA) software, such as PLAXIS or ABAQUS.

Advantages:

- Allows for detailed analysis of complex soil-structure interactions.

- Can simulate various loading scenarios and soil conditions.

Limitations:

- Requires accurate input data and advanced modeling skills.

- Results depend on the assumptions and simplifications made in the model.

4. Empirical Correlations {#empirical-correlations}

Empirical correlations use field data from similar projects to estimate pile capacity.

Examples:

- α-method: Used for cohesive soils.

- β-method: Used for non-cohesive soils.

- Nordlund Method: Combines shaft friction and end bearing capacity.

Advantages:

- Quick and easy to apply.

- Useful for preliminary design.

Limitations:

- Results may not be accurate for unique soil conditions or pile designs.

- Requires a database of reliable field data.

Case Studies and Applications {#case-studies-and-applications}

1. Bridge Foundations

Steel pipe piles are commonly used in bridge foundations due to their ability to resist high axial and lateral loads. Static load testing is often conducted to validate their capacity.

2. Marine Structures

In marine environments, steel pipe piles must withstand dynamic loads from waves and currents. Dynamic load testing and numerical modeling are used to validate their performance.

3. Offshore Platforms

Offshore platforms require deep foundations with high load-carrying capacity. Numerical modeling is frequently used to simulate pile behavior under complex loading conditions.

Challenges in Validation {#challenges-in-validation}

1. Soil Variability

Soil properties can vary significantly across a site, making it difficult to predict pile behavior accurately.

2. Cost and Time Constraints

Field testing methods, such as static load testing, are expensive and time-consuming.

3. Complex Soil-Structure Interaction

Accurately modeling the interaction between the pile and the surrounding soil requires advanced techniques and expertise.

Frequently Asked Questions (FAQ) {#faq}

1. What is the theoretical load-carrying capacity of a steel pipe pile?

The theoretical load-carrying capacity is the maximum load a pile can support, calculated based on geotechnical and structural principles.

2. How is the geotechnical capacity of a pile determined?

The geotechnical capacity is determined by analyzing the pile’s interaction with the surrounding soil, including end bearing and shaft friction.

3. What is the most reliable method for validating pile capacity?

Static load testing is the most reliable method for validating pile capacity, as it directly measures the pile’s performance under load.

4. Can numerical modeling replace field testing?

While numerical modeling is a valuable tool, it cannot fully replace field testing due to the complexity of soil-structure interactions.

5. How does soil type affect pile capacity?

Cohesive soils (e.g., clay) and non-cohesive soils (e.g., sand) interact differently with piles, influencing their shaft friction and end bearing capacity.

Related Websites : https://www.avatur.com/pipe-piles/

Conclusion {#conclusion}

The validation of theoretical load-carrying capacity is a crucial step in ensuring the safety and reliability of steel pipe piles in foundation engineering. By combining theoretical calculations with field tests, numerical modeling, and empirical correlations, engineers can accurately predict and validate the performance of steel pipe piles under real-world conditions.

Steel pipe piles continue to play a vital role in the construction of bridges, marine structures, and offshore platforms, where their ability to withstand high loads is essential. Proper validation ensures that these piles meet the required performance standards, contributing to the stability and longevity of the structures they support.