STRUCTURAL and MECHANICAL STEEL SQUARE PIPE

October 26, 2023

What is Rectangular Hollow Section (RHS) ?

October 26, 2023Square Hollow Section (SHS)

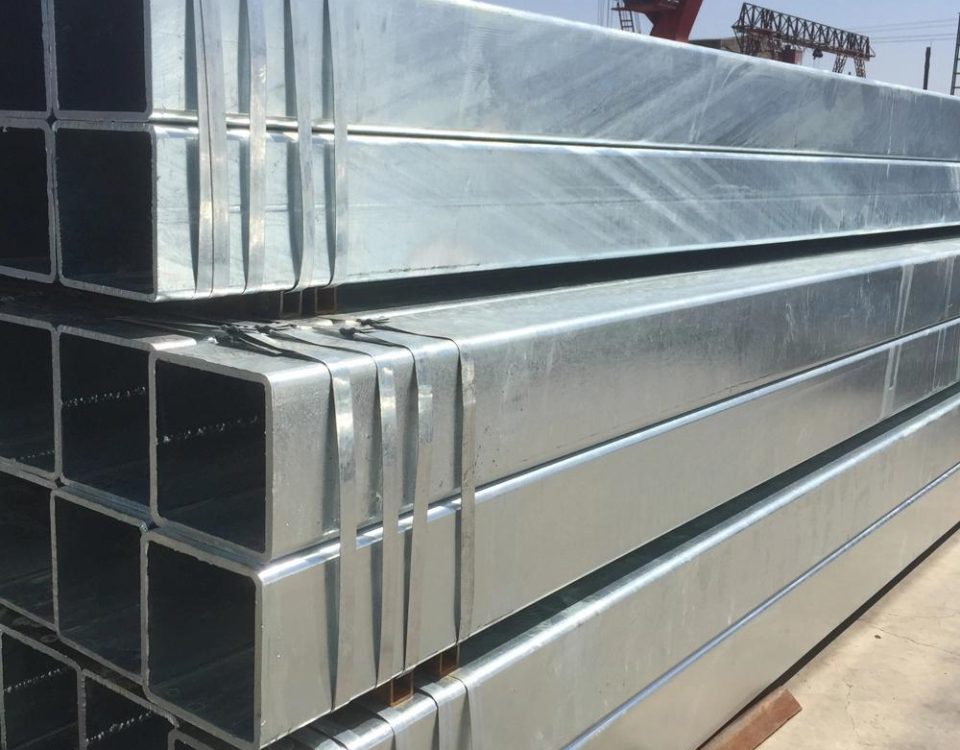

Square Hollow Section, also known as SHS, is a type of metal profile with a hollow, square tubular cross-section. It is also commonly referred to as a hollow structural section (HSS). SHS is available in both, a seamless and welded form, with the latter being the most commonly used.

Specifications of Square Hollow Section

Specifications of SHS may vary according to the standards set by different countries or organizations. Here are the specifications according to the ASTM A500 standard:

-

- Grades: Grade A, B, C, or D

- Sizes: 10mm x 10mm to 800mm x 800mm

- Wall Thickness: 0.8mm – 50mm

- Length: 3m to 12m, or custom lengths

Dimensions and Sizes of Square Hollow Section

The dimensions and sizes of SHS are quite diverse, providing a flexible option for numerous applications. Sizes can range from as small as 20mm x 20mm to as large as 500mm x 500mm, with wall thickness varying from 1.0mm to 20mm.

Chemical Composition of Square Hollow Section

The chemical composition of SHS will depend on the steel grade used. Here’s an example for the ASTM A500 Grade B:

- Carbon, max %: 0.26

- Manganese, max %: 1.35

- Phosphorous, max %: 0.04

- Sulfur, max %: 0.04

- Copper, min % when copper steel is specified: 0.20

Mechanical Property of Square Hollow Section

The mechanical properties of SHS also vary with the steel grade. For ASTM A500 Grade B:

- Tensile Strength, min, psi: 58,000

- Yield Strength, min, psi: 42,000

- Elongation in 2” min, %: 23

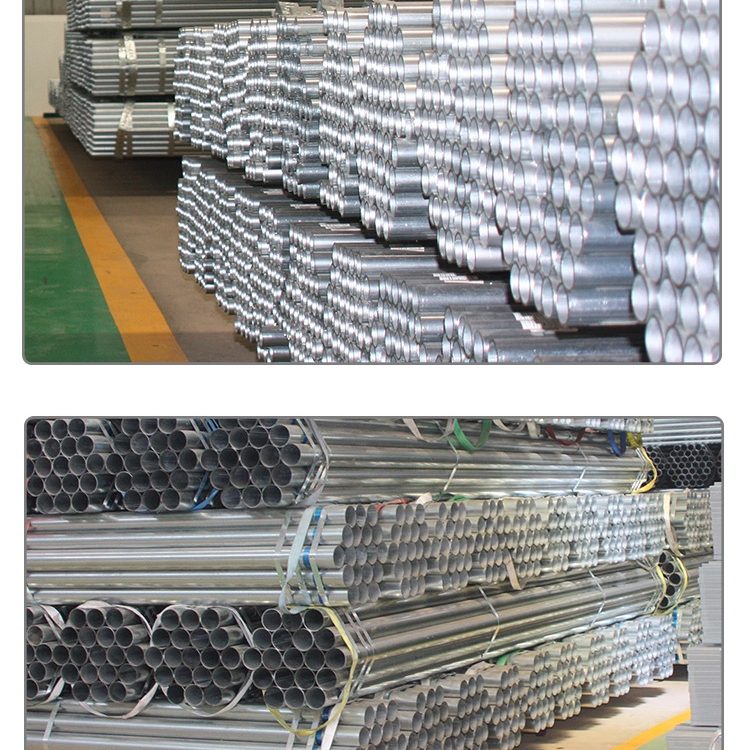

Appearance of Square Hollow Section

SHS usually have a straight and clean surface with a uniform finish. It’s possible to have surface treatments to add to its appearance and corrosion resistance, such as galvanizing, painting, or powder coating.

Advantages of Using Square Hollow Sections

- Efficiency: SHS have a high strength-to-weight ratio, making them an efficient choice in many structural applications.

- Versatility: Their symmetrical shape makes them ideal for multi-axis loading applications.

- Aesthetics: Their clean lines make them a popular choice for architectural applications.

- Ease of Fabrication: They can be cut, drilled, and welded easily.

- Durability: Their closed shape protects them from corrosion, especially when galvanized.