How Seamless Steel Pipes Shape the Backbone of Modern Industries

August 18, 2024

ASTM A268 TP410 Boiler Tubing

August 24, 2024How Do Casing Pipes Set the Standard in Performance?

Introduction

Casing pipes are essential components in various industries, particularly in the oil and gas sector, where they play a critical role in drilling and well construction. These pipes are designed to provide structural integrity and protection to wells, ensuring safe and efficient operations. This article explores how casing pipes set the standard in performance, highlighting their design features, applications, and the benefits they offer in enhancing operational efficiency and safety.

Understanding Casing Pipes

What Are Casing Pipes?

Casing pipes are large-diameter pipes used to line the walls of drilled wells, providing structural support and preventing the collapse of the wellbore. They also serve to isolate different geological formations and protect the well from external pressures and contaminants.

Types of Casing Pipes

- Conductor Casing: The first casing installed in a well, providing initial support and preventing surface soil from caving in.

- Surface Casing: Installed after the conductor casing, it isolates freshwater zones and provides additional support.

- Intermediate Casing: Used to seal off unstable formations and prevent fluid migration between geological layers.

- Production Casing: The final casing installed, facilitating the extraction of oil and gas from the well.

How Casing Pipes Set the Standard in Performance

Structural Integrity and Strength

High-Quality Materials

Casing pipes are manufactured from high-quality materials, such as carbon steel and alloy steel, ensuring exceptional strength and durability. This allows them to withstand the high pressures and temperatures encountered in drilling operations.

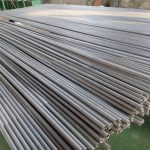

Advanced Manufacturing Techniques

The use of advanced manufacturing techniques, such as seamless pipe production and precision welding, enhances the structural integrity of casing pipes. These techniques ensure uniform wall thickness and eliminate weak points, setting a high standard for performance.

Corrosion Resistance

Protective Coatings

Casing pipes are often coated with protective materials, such as epoxy or zinc, to enhance their resistance to corrosion. This is particularly important in harsh environments, where exposure to corrosive substances can compromise the integrity of the well.

Material Selection

The selection of corrosion-resistant materials, such as stainless steel or corrosion-resistant alloys, further enhances the longevity and performance of casing pipes. This ensures reliable operation in challenging conditions.

Pressure and Temperature Tolerance

High Pressure Ratings

Casing pipes are designed to withstand the high pressures encountered during drilling and production operations. Their robust construction and high-pressure ratings ensure that they can handle the demands of deep wells and high-pressure reservoirs.

Temperature Resistance

Casing pipes are engineered to tolerate the extreme temperatures found in geothermal wells and high-temperature reservoirs. This ensures that they maintain their structural integrity and performance under challenging conditions.

Versatility and Adaptability

Customization Options

Casing pipes can be customized to meet the specific requirements of each well, including diameter, wall thickness, and material composition. This adaptability ensures optimal performance and efficiency in various applications.

Compatibility with Well Components

Casing pipes are designed to be compatible with other well components, such as tubing and wellheads, ensuring seamless integration and efficient operation. This compatibility sets a high standard for performance and reliability.

Applications of Casing Pipes

Oil and Gas Wells

Casing pipes are integral to the construction and operation of oil and gas wells, providing structural support and protection throughout the drilling and production process.

Geothermal Wells

In geothermal wells, casing pipes are used to withstand high temperatures and pressures, facilitating the extraction of geothermal energy.

Water Wells

Casing pipes are used in water wells to prevent contamination and ensure the safe extraction of groundwater for domestic, agricultural, and industrial use.

Benefits of Using Casing Pipes

Enhanced Safety

Casing pipes enhance the safety of drilling operations by preventing wellbore collapse, isolating geological formations, and protecting freshwater zones.

Improved Operational Efficiency

By providing structural support and protection, casing pipes improve the efficiency of drilling and production operations, reducing downtime and maintenance costs.

Long-Term Reliability

The durability and corrosion resistance of casing pipes ensure long-term reliability and performance, minimizing the risk of well failure and associated costs.

Conclusion

Casing pipes set the standard in performance through their exceptional strength, corrosion resistance, and adaptability. These pipes play a critical role in ensuring the safety, efficiency, and reliability of drilling and production operations across various industries. As technology and industry demands continue to evolve, casing pipes will remain a key component in setting the benchmark for performance and innovation.

FAQ

1. What are casing pipes used for in drilling operations?

Casing pipes are used to line the walls of drilled wells, providing structural support, preventing collapse, and isolating geological formations.

2. How do casing pipes enhance safety in drilling operations?

Casing pipes enhance safety by preventing wellbore collapse, isolating formations, and protecting freshwater zones from contamination.

3. What materials are commonly used for casing pipes?

Common materials for casing pipes include carbon steel, alloy steel, and corrosion-resistant alloys, chosen for their strength and durability.

4. How do casing pipes resist corrosion?

Casing pipes resist corrosion through protective coatings and the use of corrosion-resistant materials, ensuring long-term reliability.

5. What are the benefits of using casing pipes in geothermal wells?

In geothermal wells, casing pipes withstand high temperatures and pressures, facilitating efficient energy extraction and ensuring well integrity.