Internal Corrosion in Oil and Gas Wells: Challenges and Opportunities of Corrosion Inhibitors

October 18, 2024

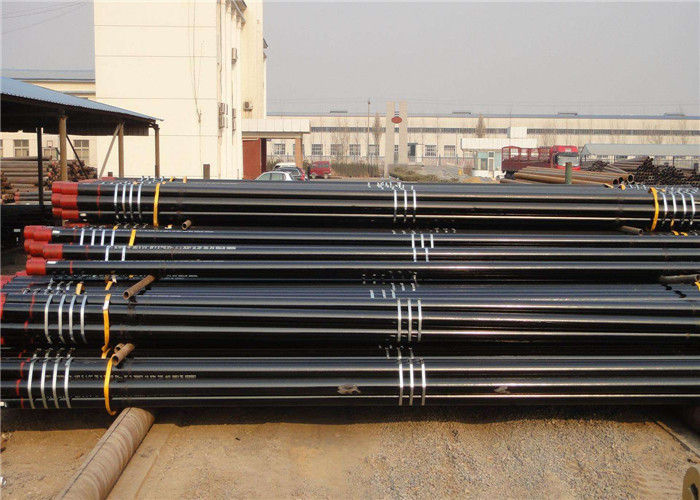

CO2 Corrosion Resistant Tubing and Casing Pipe

November 2, 2024Expansion Properties of J55 Casing Pipe

Introduction

J55 casing pipe is a commonly used grade of steel pipe in the oil and gas industry, particularly for well casing applications. It is part of the API 5CT specification, which defines the standards for casing and tubing used in oil and gas wells. J55 casing pipe is known for its moderate strength and cost-effectiveness, making it a popular choice for shallow to medium-depth wells. One of the critical properties of J55 casing pipe is its expansion property, which refers to the ability of the pipe to expand or deform under certain conditions without failure.

Understanding the expansion properties of J55 casing pipe is essential for ensuring the integrity of the wellbore and preventing issues such as collapse, burst, or failure due to thermal expansion or pressure fluctuations. In this article, we will explore the expansion properties of J55 casing pipe, including its mechanical behavior under various conditions, the factors that influence its expansion, and the testing methods used to evaluate its performance.

Table of Contents

- Overview of J55 Casing Pipe

- Mechanical Properties of J55 Casing Pipe

- 2.1 Tensile Strength

- 2.2 Yield Strength

- 2.3 Elongation

- Expansion Behavior of J55 Casing Pipe

- 3.1 Thermal Expansion

- 3.2 Elastic and Plastic Deformation

- 3.3 Collapse Resistance

- Factors Affecting Expansion of J55 Casing Pipe

- 4.1 Temperature

- 4.2 Internal Pressure

- 4.3 External Pressure

- Testing and Evaluation of Expansion Properties

- 5.1 Hydrostatic Testing

- 5.2 Thermal Expansion Testing

- 5.3 Collapse Testing

- Applications of J55 Casing Pipe

- Frequently Asked Questions (FAQ)

- Conclusion

Overview of J55 Casing Pipe {#overview-of-j55-casing-pipe}

J55 casing pipe is part of the API 5CT standard, which governs the manufacturing and performance requirements for casing and tubing used in oil and gas wells. J55 is a low-to-medium strength steel grade with a minimum yield strength of 55,000 psi (hence the designation “J55”). It is commonly used in shallow wells where the pressures and temperatures are relatively low.

The primary function of J55 casing pipe is to support the wellbore and prevent it from collapsing. It also serves as a conduit for the drilling fluid and production fluids. The pipe is subjected to various loads during its service life, including axial loads, internal pressure, external pressure, and thermal stresses. Therefore, understanding the expansion properties of J55 casing pipe is crucial for ensuring its performance under these conditions.

Mechanical Properties of J55 Casing Pipe {#mechanical-properties-of-j55-casing-pipe}

The mechanical properties of J55 casing pipe play a significant role in determining its expansion behavior. These properties include tensile strength, yield strength, and elongation.

2.1 Tensile Strength {#tensile-strength}

The tensile strength of J55 casing pipe refers to the maximum stress that the material can withstand while being stretched or pulled before breaking. For J55, the typical tensile strength is around 75,000 psi. This property is important when considering the pipe’s ability to resist axial loads and deformation.

2.2 Yield Strength {#yield-strength}

The yield strength of J55 casing pipe is the stress at which the material begins to deform plastically. For J55, the minimum yield strength is 55,000 psi. Once the yield point is exceeded, the pipe will undergo permanent deformation. The yield strength is a critical factor in determining the pipe’s ability to withstand internal and external pressures without permanent deformation.

2.3 Elongation {#elongation}

Elongation is a measure of the material’s ductility, or its ability to stretch before breaking. For J55 casing pipe, the typical elongation is around 19-22%. This means that the pipe can undergo a certain amount of stretching or deformation before it fractures. Elongation is an important property when considering the pipe’s ability to expand under pressure or thermal stress.

Expansion Behavior of J55 Casing Pipe {#expansion-behavior-of-j55-casing-pipe}

The expansion behavior of J55 casing pipe is influenced by several factors, including thermal expansion, elastic and plastic deformation, and collapse resistance.

3.1 Thermal Expansion {#thermal-expansion}

Thermal expansion refers to the tendency of the pipe to expand when exposed to elevated temperatures. Like all materials, carbon steel expands when heated and contracts when cooled. The coefficient of thermal expansion for carbon steel, including J55, is approximately 12 x 10^-6 /°C. This means that for every degree Celsius increase in temperature, the pipe will expand by 12 micrometers per meter of length.

In oil and gas wells, temperature fluctuations can occur due to changes in the geothermal gradient or the injection of hot fluids. If the casing pipe is subjected to significant temperature changes, it may expand or contract, leading to additional stresses on the pipe. Therefore, it is essential to consider the thermal expansion properties of J55 casing pipe when designing wellbore systems.

3.2 Elastic and Plastic Deformation {#elastic-and-plastic-deformation}

When subjected to external forces, J55 casing pipe can undergo elastic or plastic deformation.

- Elastic deformation occurs when the pipe is subjected to stress but returns to its original shape once the stress is removed. This type of deformation is temporary and occurs within the elastic limit of the material.

- Plastic deformation, on the other hand, occurs when the stress exceeds the yield strength of the material, resulting in permanent deformation. Once the pipe has deformed plastically, it will not return to its original shape even after the stress is removed.

The ability of J55 casing pipe to withstand elastic deformation without permanent damage is critical for its performance in wellbore applications. However, if the pipe is subjected to stresses beyond its yield strength, it may undergo plastic deformation, leading to permanent expansion or failure.

3.3 Collapse Resistance {#collapse-resistance}

Collapse resistance refers to the ability of the casing pipe to withstand external pressure without collapsing. In oil and gas wells, the external pressure on the casing can be significant, especially at greater depths. The collapse resistance of J55 casing pipe is influenced by its wall thickness, material strength, and the external pressure acting on the pipe.

The collapse pressure for J55 casing pipe can be calculated using the following formula:

Where:

- PcP_c = Collapse pressure

- EE = Modulus of elasticity of the material

- tt = Wall thickness of the pipe

- DD = Outer diameter of the pipe

J55 casing pipe has moderate collapse resistance, making it suitable for shallow to medium-depth wells where external pressures are relatively low. However, for deeper wells, higher-grade casing pipes with greater collapse resistance may be required.

Factors Affecting Expansion of J55 Casing Pipe {#factors-affecting-expansion}

Several factors can influence the expansion behavior of J55 casing pipe, including temperature, internal pressure, and external pressure.

4.1 Temperature {#temperature}

As mentioned earlier, temperature fluctuations can cause the casing pipe to expand or contract. In oil and gas wells, the temperature can vary significantly depending on the depth of the well and the geothermal gradient. Additionally, the injection of hot fluids or steam can cause the casing to expand. If the pipe is not designed to accommodate thermal expansion, it may experience additional stresses, leading to deformation or failure.

4.2 Internal Pressure {#internal-pressure}

Internal pressure is the pressure exerted by the fluids inside the casing pipe. As the internal pressure increases, the pipe may expand radially. The ability of J55 casing pipe to withstand internal pressure without excessive expansion or failure is critical for maintaining the integrity of the wellbore. The internal pressure rating of J55 casing pipe is typically lower than that of higher-grade casing pipes, making it suitable for shallow wells with moderate pressure conditions.

4.3 External Pressure {#external-pressure}

External pressure is the pressure exerted on the outside of the casing pipe by the surrounding formation or drilling fluid. In deep wells, the external pressure can be significant, and if the casing pipe is not strong enough to resist this pressure, it may collapse. The collapse resistance of J55 casing pipe is moderate, making it suitable for wells with low to moderate external pressures.

Testing and Evaluation of Expansion Properties {#testing-and-evaluation}

Several testing methods are used to evaluate the expansion properties of J55 casing pipe, including hydrostatic testing, thermal expansion testing, and collapse testing.

5.1 Hydrostatic Testing {#hydrostatic-testing}

Hydrostatic testing is used to evaluate the ability of the casing pipe to withstand internal pressure without leaking or expanding excessively. During the test, the pipe is filled with water and pressurized to a predetermined level. The pipe is then inspected for signs of leakage or deformation. Hydrostatic testing is commonly used to verify the integrity of the casing pipe before it is installed in the wellbore.

5.2 Thermal Expansion Testing {#thermal-expansion-testing}

Thermal expansion testing is used to evaluate the expansion behavior of the casing pipe when exposed to elevated temperatures. The pipe is heated to a specific temperature, and the amount of expansion is measured. This test helps determine the coefficient of thermal expansion for the material and its ability to withstand thermal stresses.

5.3 Collapse Testing {#collapse-testing}

Collapse testing is used to evaluate the collapse resistance of the casing pipe. During the test, the pipe is subjected to external pressure until it collapses. The collapse pressure is then recorded and compared to the theoretical collapse pressure calculated using the pipe’s dimensions and material properties. Collapse testing is essential for determining the suitability of the casing pipe for use in deep wells with high external pressures.

Applications of J55 Casing Pipe {#applications-of-j55-casing-pipe}

J55 casing pipe is widely used in the oil and gas industry for various applications, including:

- Shallow Wells: J55 casing pipe is commonly used in shallow wells where the pressures and temperatures are relatively low.

- Water Wells: J55 casing pipe is also used in water well applications due to its moderate strength and cost-effectiveness.

- Geothermal Wells: In some cases, J55 casing pipe is used in geothermal wells where the temperatures are moderate, and the external pressures are not too high.

Frequently Asked Questions (FAQ) {#faq}

1. What is the thermal expansion coefficient of J55 casing pipe?

The thermal expansion coefficient of J55 casing pipe is approximately 12 x 10^-6 /°C. This means that for every degree Celsius increase in temperature, the pipe will expand by 12 micrometers per meter of length.

2. How does internal pressure affect the expansion of J55 casing pipe?

As internal pressure increases, the casing pipe may expand radially. The ability of J55 casing pipe to withstand internal pressure without excessive expansion or failure is critical for maintaining the integrity of the wellbore.

3. What is the collapse resistance of J55 casing pipe?

The collapse resistance of J55 casing pipe depends on its wall thickness, material strength, and external pressure. J55 casing pipe has moderate collapse resistance, making it suitable for shallow to medium-depth wells.

4. How is the expansion behavior of J55 casing pipe tested?

The expansion behavior of J55 casing pipe is tested using methods such as hydrostatic testing, thermal expansion testing, and collapse testing. These tests evaluate the pipe’s ability to withstand internal and external pressures, as well as temperature fluctuations.

5. What are the typical applications of J55 casing pipe?

J55 casing pipe is commonly used in shallow wells, water wells, and geothermal wells. It is suitable for applications where the pressures and temperatures are relatively low.

Conclusion {#conclusion}

The expansion properties of J55 casing pipe are critical for ensuring its performance in oil and gas well applications. Understanding how J55 casing pipe behaves under various conditions, including temperature fluctuations, internal pressure, and external pressure, is essential for maintaining the integrity of the wellbore. By conducting thorough testing and selecting the appropriate casing pipe for the specific well conditions, operators can prevent issues such as collapse, burst, or failure due to thermal expansion or pressure fluctuations.