Outline for Steel Pipe: Coatings, Design, & Installation

October 7, 2024

New Energy Steel Pipes

October 13, 2024Introduction

Steel water pipes are a cornerstone of modern infrastructure, playing a critical role in the distribution of water across urban and rural landscapes. Their design, lining, coating, joints, and installation are crucial factors that determine their efficiency, durability, and longevity. This comprehensive guide explores each of these aspects in detail, providing insights into best practices, innovations, and future trends in the field.

1. Understanding Steel Water Pipes

Steel water pipes are cylindrical tubes made from steel, used primarily for transporting water over long distances. They are favored for their strength, durability, and ability to withstand high pressures and temperatures. The choice of steel as a material is due to its excellent mechanical properties and adaptability to various environmental conditions.

2. Importance of Design in Steel Water Pipes

The design of steel water pipes is a critical factor that influences their performance and longevity. A well-designed pipe system ensures efficient water flow, minimizes energy consumption, and reduces the risk of leaks and failures.

2.1 Material Selection

Choosing the right type of steel is essential for ensuring the pipe’s durability and resistance to corrosion. Factors such as the water’s chemical composition, temperature, and pressure must be considered when selecting materials.

2.2 Pipe Diameter and Thickness

The diameter and thickness of the pipes are determined by the expected flow rate and pressure. Larger diameters are used for high-volume applications, while thicker walls provide additional strength and resistance to external forces.

2.3 Joint Design

Joints are critical components of a pipe system, as they connect individual pipe sections and ensure a leak-proof seal. The design of joints must consider factors such as flexibility, ease of installation, and resistance to pressure and temperature changes.

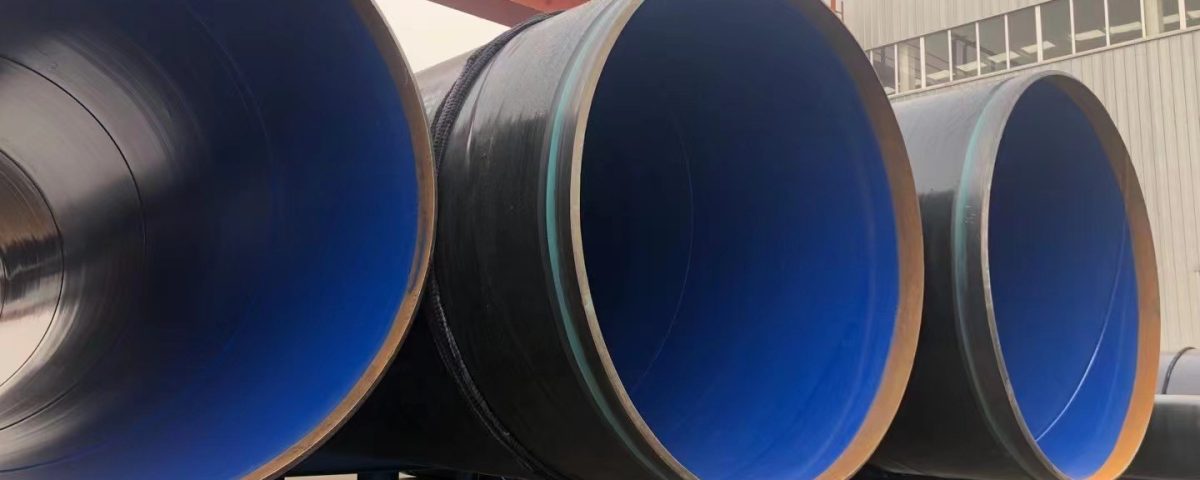

3. Lining of Steel Water Pipes

Lining is an essential aspect of steel water pipes, providing a protective barrier between the water and the pipe material. It prevents corrosion, reduces friction, and improves the pipe’s overall performance.

3.1 Types of Linings

- Cement Mortar Lining: A common choice for water pipes, cement mortar lining provides a smooth surface that reduces friction and prevents corrosion.

- Epoxy Lining: Known for its excellent adhesion and chemical resistance, epoxy lining is used in pipes exposed to aggressive water conditions.

- Polyurethane Lining: Offers a durable and flexible barrier, ideal for pipes subjected to temperature fluctuations and mechanical stress.

3.2 Benefits of Proper Lining

Proper lining of steel water pipes offers several benefits:

- Corrosion Protection: Prevents the pipe material from reacting with water, reducing the risk of leaks and failures.

- Improved Flow Efficiency: A smooth lining reduces friction, enhancing water flow and reducing energy consumption.

- Extended Lifespan: Protects the pipe from wear and tear, increasing its durability and longevity.

4. Coating of Steel Water Pipes

Coatings provide an additional layer of protection for steel water pipes, shielding them from external environmental factors such as moisture, chemicals, and UV radiation.

4.1 Types of Coatings

- Fusion Bonded Epoxy (FBE): A popular choice for its strong adhesion and resistance to high temperatures and chemicals.

- Polyethylene Coating: Provides excellent moisture resistance and is commonly used for underground pipes.

- Bituminous Coating: Offers a cost-effective solution for protecting pipes from corrosion and abrasion.

4.2 Benefits of Proper Coating

- Enhanced Durability: Protects the pipe from external damage, extending its service life.

- Reduced Maintenance Costs: Minimizes the need for frequent repairs and replacements.

- Improved Safety: Prevents leaks and structural failures, ensuring safe operation.

5. Joints in Steel Water Pipes

Joints are crucial components of a steel water pipe system, connecting individual pipe sections and ensuring a continuous, leak-proof flow of water.

5.1 Types of Joints

- Welded Joints: Provide a strong and permanent connection, ideal for high-pressure applications.

- Flanged Joints: Allow for easy assembly and disassembly, making them suitable for maintenance and repair work.

- Mechanical Couplings: Offer flexibility and ease of installation, accommodating slight misalignments and movements.

5.2 Considerations for Joint Design

- Flexibility: Joints must accommodate thermal expansion and contraction, as well as ground movement.

- Ease of Installation: Simple and efficient joint designs reduce installation time and labor costs.

- Leak Resistance: Ensuring a tight seal is crucial for preventing leaks and maintaining system integrity.

6. Installation of Steel Water Pipes

The installation of steel water pipes involves several steps to ensure proper alignment, connection, and support. A well-executed installation process is critical for the system’s overall performance and longevity.

6.1 Preparing for Installation

- Site Assessment: Evaluating the installation site for potential challenges and hazards.

- Material Inspection: Checking pipes and fittings for defects or damage before installation.

- Equipment Setup: Ensuring all necessary tools and equipment are available and in good working condition.

6.2 Installation Process

The installation process typically involves the following steps:

- Laying Out the Pipes: Positioning the pipes according to the design plan.

- Joining the Pipes: Using appropriate methods such as welding or mechanical couplings.

- Securing the Pipes: Installing supports and anchors to maintain alignment and stability.

6.3 Welding Techniques for Steel Pipes

Welding is a common method for joining steel pipes, offering strong and leak-proof connections. Various techniques are used, including:

- Arc Welding: A versatile and widely used method for steel pipe welding.

- TIG Welding: Provides precise control and high-quality welds, ideal for thin-walled pipes.

- MIG Welding: Offers fast and efficient welding for large-scale projects.

7. Quality Control and Testing

Ensuring the quality and integrity of steel water pipes is essential for safe and reliable operation:

- Visual Inspections: Checking for visible defects and ensuring proper alignment.

- Pressure Testing: Verifying the pipes can withstand the expected pressure without leaks.

- Non-Destructive Testing (NDT): Using techniques like ultrasonic testing to detect internal flaws.

8. Maintenance of Steel Water Pipes

Regular maintenance is crucial to prevent corrosion and extend the lifespan of steel water pipes:

- Inspection Schedules: Conducting routine inspections to identify and address coating and lining damage.

- Repair Techniques: Applying touch-up coatings or replacing damaged sections as needed.

- Environmental Considerations: Ensuring maintenance practices comply with environmental regulations.

9. Environmental Impact

The production, installation, and maintenance of steel water pipes can have environmental implications. It’s important to consider:

- Sustainable Materials: Using eco-friendly coatings and materials to reduce environmental impact.

- Waste Management: Proper disposal of waste materials and minimizing emissions during installation.

- Energy Efficiency: Implementing energy-saving practices in the production and installation processes.

10. Innovations in Pipe Coatings and Linings

Advancements in coating and lining technology continue to improve the performance and durability of steel water pipes:

- Nanotechnology: Developing coatings with enhanced properties such as self-healing and increased resistance to abrasion.

- Smart Coatings: Incorporating sensors and monitoring capabilities to detect and report damage or wear.

- Bio-based Coatings: Using renewable materials to create environmentally friendly coatings.

11. Future Trends in Pipe Design and Installation

The future of steel water pipe design and installation is shaped by emerging technologies and changing industry demands:

- Advanced Materials: Exploring new alloys and composites for improved strength and corrosion resistance.

- Digital Design Tools: Utilizing software and simulations to optimize pipe design and performance.

- Integrated Systems: Designing pipes as part of larger, interconnected systems for enhanced efficiency and control.

12. Case Studies on Successful Installations

Examining real-world examples of successful steel water pipe installations provides valuable insights into best practices and lessons learned:

- Project A: Highlighting innovative design and installation techniques used in a large-scale pipeline project.

- Project B: Discussing the challenges and solutions implemented in a complex urban infrastructure installation.

- Project C: Showcasing the benefits of advanced coatings in a high-corrosion environment.

13. Safety Measures during Installation

Ensuring the safety of workers and the surrounding environment is paramount during steel water pipe installation:

- Personal Protective Equipment (PPE): Providing appropriate gear to protect workers from hazards.

- Safety Protocols: Implementing procedures to prevent accidents and injuries.

- Emergency Preparedness: Having plans in place to respond to incidents quickly and effectively.

Conclusion

Steel water pipes are vital components of modern infrastructure, and their performance depends on careful consideration of design, lining, coating, joints, and installation. By staying informed about the latest advancements and best practices, industries can ensure the safe, efficient, and sustainable use of steel water pipes for years to come.