ASTM A1110 Đường ống kết cấu thép liền mạch

Tháng mười 8, 2025

Ống thép nặng – Chất liệu thép ST37 15Mo3 C45

Tháng mười 14, 2025ASTM A860 WPHY 52 và WPHY 65 Phụ kiện uốn cong bằng thép carbon: Kỹ thuật chính xác cho đường ống áp suất cao

Trong nhịp đập không ngừng của nền công nghiệp hiện đại, nơi đường ống xuyên qua núi, lặn dưới đại dương, và rắn rỏi băng qua những sa mạc rộng lớn để cung cấp huyết mạch cho nền kinh tế—dầu thô, khí đốt tự nhiên, và các sản phẩm tinh chế—không thể phóng đại vai trò của các phụ kiện đáng tin cậy. Nhập tiêu chuẩn ASTM A860 WPHY 52 và WPHY 65 phụ kiện uốn thép carbon: những anh hùng khiêm tốn nhưng không thể thiếu trong bản giao hưởng của hệ thống truyền tải cao áp. Những thành phần thép ferritic năng suất cao được rèn này, được thiết kế đặc biệt cho các ứng dụng hàn giáp mép, thể hiện đỉnh cao của sự khéo léo luyện kim, Cung cấp sức mạnh chưa từng có, độ dẻo, và khả năng hàn để điều hướng các khúc quanh của cơ sở hạ tầng đòi hỏi khắt khe. Tính đến tháng 10 2025, với nhu cầu năng lượng toàn cầu tăng cao trong bối cảnh chuyển đổi sang các nguồn năng lượng bền vững, những phụ kiện này vẫn là nền tảng cho những gã khổng lồ về dầu khí, nhà máy lọc hóa dầu, và thậm chí cả mạng lưới hydro mới nổi, đảm bảo dòng chảy liền mạch nơi những đường thẳng không dám bước đi.

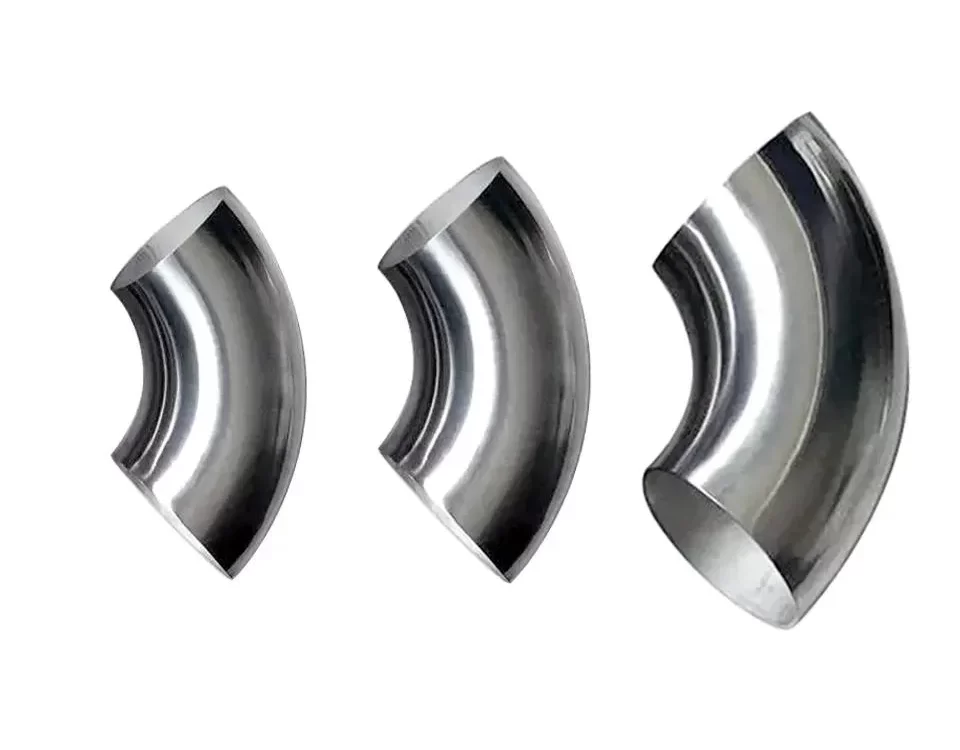

Hình ảnh hiện trường: một nền tảng ngoài khơi rộng lớn ở Biển Bắc, bị vùi dập bởi gió giật và sóng biển, các phần nhô lên dưới biển của nó cuộn tròn như những con rắn dưới áp suất thủy tĩnh cực lớn. Đây, một WPHY 65 khớp nối uốn cong—cong một cách chính xác 90 độ với bán kính dài để giảm thiểu nhiễu loạn—giữ nguyên đường, của nó 65 ksi cường độ năng suất tối thiểu bất chấp 2,500 psi trong khi chống lại sự ăn mòn của môi trường nước mặn. Chuyển sang các giàn khoan đầy bụi ở lưu vực Permian, ở đâu WPHY 52 uốn cong dẫn hydrocarbon fracking qua các đường tập kết tại 1,440 psi, thấp hơn nhưng mạnh mẽ của họ 52 năng suất ksi mang lại khả năng phục hồi hiệu quả về mặt chi phí mà không cần vượt quá. Công ty của chúng tôi, tiên phong trong sản xuất chính xác, chế tạo những khúc cua này không chỉ đơn thuần là những điểm kết nối mà còn là những dây cứu sinh được thiết kế, vẽ từ thập kỷ của R&D để kết hợp các tiêu chuẩn khắt khe của ASTM A860 với khả năng thích ứng trong thế giới thực. Mỗi mảnh nổi lên từ lò uốn cảm ứng hoặc máy ép tạo hình nóng, dập tắt và tôi luyện đến mức hoàn hảo, sẵn sàng tồn tại lâu hơn những chu kỳ mở rộng khắc nghiệt nhất, sự co lại, và rung động.

Đi sâu vào trung tâm phân tử của những phụ kiện này, hóa học là một lớp học bậc thầy về sự cân bằng. Dành cho WPHY 52, mũ carbon tại 0.20% để tăng cường độ cứng mà không bị giòn, vũ điệu mangan giữa 0.60-1.40% để tăng cường độ dẻo dai, và các nguyên tố vi hợp kim như vanadi (tối đa 0.12%) và niobi (tối đa 0.05%) tinh chỉnh cấu trúc hạt để có khả năng chống va đập vượt trội. Phốt pho và lưu huỳnh bị trói buộc bên dưới 0.030% và 0.015%, tương ứng, để tránh nứt vùng hàn, trong khi silicon (0.15-0.40%) tăng cường khả năng chống oxy hóa. WPHY 65 tăng cường tiền cược: cạnh carbon để 0.23%, mangan giữ ổn định, nhưng vanadi leo lên 0.20% và molypden để 0.25%, dệt nên một ma trận chặt chẽ hơn nhằm nâng cao năng suất lên 65 KSI (450 MPa) và kéo tới 530-705 MPa. Đây không phải là hợp kim ngẫu nhiên; đó là thuật giả kim có tính toán, với lượng cacbon tương đương (CE) nghiêm ngặt theo 0.42% (CE = C + Mn/6 + (CR + Mo + V)/5 + (Ni + Cu)/15) để đảm bảo hàn không cần gia nhiệt trước ngay cả trong điều kiện hiện trường. Có nguồn gốc từ ống API 5L X52 hoặc X65 cao cấp, phôi thép của chúng tôi trải qua quá trình nấu chảy cảm ứng chân không để có tạp chất cực thấp, được xác minh bằng máy quang phổ PMI—vì ở chỗ uốn cong có đường kính 48 inch, một tạp chất lừa đảo có thể dẫn đến thất bại thảm hại.

Từ nền tảng cơ bản này chảy ra tính nghệ thuật của hình thức: kích thước phù hợp với tường thuật của đường ống. Các phụ kiện uốn cong ở các cấp này trải dài trên các kết cấu liền mạch từ NPS 1/2″ -24″, bức tường từ SCH 10 (0.109″ gầy) đến xxs (lên tới 1,732″ dày cho những người khổng lồ), và các biến thể hàn được đẩy lên NPS 48″ hoặc hơn thế nữa đối với các dự án lớn. Bán kính thay đổi một cách thơ mộng—1D viết tắt của đa tạp nhà máy lọc dầu nhỏ gọn, 1.5D mong muốn có những lần quét hiệu quả về chất lỏng giúp giảm áp suất giảm đi 20-30%, tùy chỉnh lên tới 5D cho các dây chuyền có thể di chuyển được trong đó các công cụ kiểm tra nội tuyến lướt qua không bị cản trở. góc? 45° cho các chuyển hướng tinh tế, 90° để rẽ vuông góc, 180° trả về cho các vòng trao đổi nhiệt. Dung sai tuân theo ASME B16.9: CỦA ±1%, tường ±12,5%, với các đầu được vát ở góc 37,5° ±2,5° cho các mối hàn giáp mép hoàn hảo. Cân nặng từ 0.5 lb/ft cho nhỏ nhắn 2″ uốn cong để 500 khổng lồ lb/ft, tất cả đều được thử nghiệm thủy tĩnh tới 1,5 lần MAOP (áp suất vận hành tối đa cho phép), thường 2,500 psi hoặc cao hơn. Tại cơ sở hiện đại của chúng tôi, Uốn trục CNC bảo vệ tính đồng nhất của tường, loại bỏ việc đánh trứng phổ biến ở các phương pháp ít hơn, trong khi quét UT sau uốn xác nhận không cán màng.

Tiêu chuẩn không chỉ là những hộp kiểm; chúng là giao ước không thể phá vỡ đảm bảo khả năng tương tác và an toàn. ASTM A860/M, thông số kỹ thuật quản lý kể từ 1995 (bản sửa đổi mới nhất 2023), bắt buộc sử dụng thép ferritic rèn cho các phụ kiện hàn đối đầu, với các điểm được khóa để mang lại năng suất: WPHY 52 tại 52 ksi phút, WPHY 65 tại 65 KSI. ASME B16.9 quy định kích thước cho các phụ kiện rèn do nhà máy sản xuất, trong khi MSS SP-75 mở rộng các yêu cầu kiểm tra cao cho NPS 14″+ và sản lượng >52 KSI, căn chỉnh liền mạch với API 5L cho đường ống khả năng tương thích. Cho dịch vụ chua (Môi trường H2S), NACE MR0175/ISO 15156 tuân thủ kiềm chế vết nứt căng thẳng sunfua, với giới hạn độ cứng ở HB 197. Các biến thể nhiệt độ thấp giảm xuống -29°C Charpy V-Notch (25 ft-lb phút), và PED 2014/68/EU đồng ý sử dụng thiết bị áp lực của EU. Bản giao hưởng QA của chúng tôi bao gồm 100% RT cho mối hàn, MT/PT cho bề mặt, và truy xuất nguồn gốc đầy đủ thông qua việc dập lô nhiệt—chứng chỉ nhà máy ở EN 10204 3.1định dạng B, bởi vì trách nhiệm giải trình là nền tảng của niềm tin trong kỷ nguyên giám sát pháp lý.

7Lắp ống uốn cong D: Thép Carbon 7D uốn cong, ASTM A860, lắp đường ống, Lớp F304, F304L, F316, F316L, Lịch trình 5-160, ANSI, TIÊU CHUẨN ISO, JIS và DIN.

Thông số kỹ thuật vẽ nên bức chân dung về hiệu suất dưới áp lực. Về mặt máy móc, WPHY 52 mang lại 52 năng suất ksi (360 MPa), 66-92 độ bền kéo ksi (455-630 MPa), 22% độ giãn dài tối thiểu, bảo vệ chống đứt dẻo khi chịu tải theo chu kỳ. WPHY 65 tăng tiền cược: 65 năng suất ksi (450 MPa), 77-100 độ bền kéo ksi (530-690 MPa), 20% ly giác, với tỷ lệ năng suất trên độ bền kéo ≤0,85 để tránh bị căng quá mức. Độ cứng? Brinell 163-197 cho cả hai, đảm bảo khả năng gia công mà không làm mất khả năng giữ cạnh. sự ăn mòn? <0.1 mm/năm ở đất trung tính, được tăng cường bởi FBE (epoxy liên kết nhiệt hạch) hoặc lớp phủ 3LPE cho tuổi thọ ngoài khơi. Động lực dòng chảy ủng hộ các đường dẫn tầng: hệ số K 0.2-0.4 cho các khúc cua 1,5D, giảm xói mòn bằng cách 25% so với khớp miter sắc nét. Tính chất nhiệt tỏa sáng—mật độ 7.85 g/cm³ cho hiệu quả địa chấn, độ dẫn điện 52 W/m·K cho bộ trao đổi nhiệt, mô đun 200 GPa cho mô hình FEA. Đã được thử nghiệm ở áp suất gấp 4 lần, uốn cong theo tiêu chuẩn ASTM E290 (không có vết nứt ở bán kính 3x), những thông số kỹ thuật này không phải là sự tò mò trong phòng thí nghiệm; chúng đã được chứng minh qua chiến đấu trong các mô phỏng phản ánh tuổi thọ 50 năm, từ chu trình nhiệt ở 650°F đến mài mòn bởi 20% chất rắn.

Các ứng dụng mở ra như một bản đồ toàn cầu về các mạch năng lượng. Trong dầu & truyền khí đốt—hãy nghĩ đến Đường ống xuyên Alaska hoặc việc mở rộng North Field của Qatar—WPHY 65 uốn cong neo dòng chảy khối lượng lớn tại 1,440-2,000 psi, độ dẻo dai của chúng ngăn cản sự oằn từ sự giãn nở ΔT lên đến 100°F. WPHY 52 phù hợp với việc tụ tập giữa dòng, tối ưu hóa chi phí cho 1,000 đá phiến psi đóng vai trò. Các nhà máy lọc dầu triển khai chúng trong các máy xử lý bằng hydro (900° F, 2,000 psi), nơi tính toàn vẹn liền mạch ngăn chặn rò rỉ hydrocarbon gây thiệt hại hàng triệu USD mỗi ngày. Khai thác hóa dầu WPHY 65 cho bánh quy giòn ethylene, chống lại stress clorua; máy phát điện định tuyến hơi nước siêu tới hạn tại 1,000 psi. Ngoài hóa thạch, họ đang chuyển hướng sang CCS (cô lập CO2) đường dây và đường ống H2, nơi năng suất cao đáp ứng khả năng chống giòn. Khai thác bùn tại 15% chất rắn? WPHY 52 lá chắn chống mài mòn. Phun nước cho EOR? Cả hai lớp dẫn nước muối qua sa mạc. Những khách hàng như Chevron hay Aramco tích hợp chúng vào các chế độ heo thông minh, chán Ra <50 μin đảm bảo ILI chạy hoàn hảo. Từ LNG Bắc Cực đến máy phân tách vùng Vịnh, những khúc cua này thích ứng, tính linh hoạt của chúng một cuộc cách mạng thầm lặng trong cơ sở hạ tầng kiên cường.

Các tính năng nâng họ từ hàng hóa thành nhà vô địch. Cường độ năng suất cao cho phép các bức tường mỏng hơn (15% tiết kiệm vật liệu) không có sự đánh đổi về an toàn, cắt giảm chi phí vận chuyển và lắp đặt. Khả năng hàn là tuyệt vời: CE <0.42% cho phép GTAW/SMAW không có PWHT cho độ dày <3″, phản ứng tổng hợp trên ASME IX với RT trên B31.3. Cấu trúc rèn đẳng hướng mang lại các đặc tính đồng nhất—không có khuyết tật đúc— với CVN >25 ft-lb ở -20°F dành cho các ứng dụng quan trọng về gãy xương. Khả năng định dạng tỏa sáng: uốn nguội đến bán kính 3D không bị nứt, cảm ứng nóng cho đường cong không bị biến dạng. Cạnh sinh thái? 100% tái chế, 50+ năm tuổi thọ hạn chế khí thải. Chỉnh sửa tùy chỉnh—ID có thể lợn được, bọc Inconel cho nhiệm vụ chua chát, hoặc lớp lót HDPE để chống mài mòn—làm theo yêu cầu riêng. So với gang hoặc WPB cấp thấp hơn, họ tự hào về MTBF gấp đôi, giảm TCO xuống 20%.

Để neo tấm thảm này, bàn chưng cất tinh chất:

Thành phần vật liệu (Trọng lượng %)

| Lớp | C Tối đa | Mn | P Max | S Max | Si | Cr Max | Ni Max | Mo Max | V Max | Khác |

|---|---|---|---|---|---|---|---|---|---|---|

| WPHY 52 | 0.20 | 0.60-1.40 | 0.030 | 0.015 | 0.15-0.40 | 0.30 | 0.40 | 0.15 | 0.12 | NB 0.05, Ti 0.05, Cu 0.35 |

| WPHY 65 | 0.23 | 0.60-1.40 | 0.030 | 0.015 | 0.15-0.45 | 0.30 | 0.50 | 0.25 | 0.20 | NB 0.10, Ti 0.05, Ống / Ống thép hợp kim liền mạch 0.02 |

Kích thước và kích cỡ

| Loại hình | Phạm vi NPS (ở) | Lịch treo tường | Bán kính uốn cong | Góc (°) | Trọng lượng (lb/ft) |

|---|---|---|---|---|---|

| Dàn | 1/2 – 24 | SCH 10 – XXS | 1D – 5D | 45-180 | 0.5 – 150 |

| Hàn | 2 – 48 | SCH 5 – XXS | 1D – Phong tục | 30-180 | 5 – 500 |

| uốn cong cụ thể | 4 – 36 | SCH 20 – 80 | 1.5Dmin | 90, 180 | 10 – 300 |

Tiêu chuẩn và tuân thủ

| Tiêu chuẩn | Sự miêu tả | Khả năng ứng dụng |

|---|---|---|

| ASTM A860/M | Các phụ kiện hàn đối đầu Ferritic năng suất cao | Thông số cốt lõi cho các lớp WPHY |

| ASME B16.9 | Phụ kiện hàn đối đầu do nhà máy sản xuất | Kích thước, dung sai |

| MSS SP-75 | Phụ kiện hàn giáp mép rèn thử nghiệm cao | NPS >14″, sản lượng >52 KSI |

| NACE MR0175 | Khả năng chống nứt ứng suất sunfua | Dịch vụ chua (H2S) |

| API 5L | Khả năng tương thích đường ống | Căn chỉnh năng suất với X52/X65 |

Thông số kỹ thuật (Tính chất cơ học)

| Tham số | WPHY 52 Giá trị | WPHY 65 Giá trị | Phương pháp kiểm tra |

|---|---|---|---|

| Năng suất sức mạnh tối thiểu | 52 KSI (360 MPa) | 65 KSI (450 MPa) | ASTM A370 |

| Độ bền kéo | 66-92 KSI (455-630 MPa) | 77-100 KSI (530-690 MPa) | ASTM A370 |

| Kéo dài tối thiểu | 22% | 20% | ASTM A370 |

| Độ cứng tối đa (HB) | 197 | 197 | ASTM E10 |

| Tác động của CVN @ -20°F | 25 ft-lb phút | 25 ft-lb phút | ASTM A370 |

| Đánh giá áp suất | Lên đến 2500 psi | Lên đến 2500 psi | ASME B31.3 |

Tham số chính

| Tài sản | Giá trị/Phạm vi | Ghi chú |

|---|---|---|

| Mật độ | 7.85 g / cm³ | cân nặng, thiết kế địa chấn |

| Dẫn nhiệt | 52 W/m·K | Tản nhiệt trong dịch vụ |

| Mô đun đàn hồi | 200 GPa | Mô hình độ cứng FEA |

| Tỷ lệ ăn mòn | <0.1 mm/năm (trung lập) | Cải thiện với lớp phủ FBE/3LPE |

| Hệ số dòng chảy (K) | 0.2-0.4 (1.5uốn cong chữ D) | Giảm áp suất, giảm xói mòn |

Ứng dụng

| Công nghiệp | Sử dụng trường hợp | Lớp ưa thích |

|---|---|---|

| Dầu & Khí | Đường ống truyền tải, tăng | WPHY 65 |

| Nhà máy lọc dầu | Hydrocrackers, vòng lặp quá trình | WPHY 52/65 |

| hóa dầu | Đơn vị ethylene, dòng nhiệt độ cao | WPHY 65 |

| Máy phát điện | Đường ống hơi nước, thức ăn cho nồi hơi | WPHY 52 |

| Khai thác/Nước | Vận chuyển bùn, đường tiêm | WPHY 52 |

Tính năng

| Tính năng | Lợi ích | Lợi thế |

|---|---|---|

| Sức mạnh năng suất cao | Khả năng chống biến dạng ở áp suất | Tường mỏng hơn, 15% tiết kiệm chi phí |

| Tính hàn | CE thấp cho các kết nối không có PWHT | Cài đặt trường nhanh hơn |

| độ dẻo dai | Dễ uốn ở nhiệt độ thấp (-29° C) | An toàn hơn ở Bắc Cực/ngoài khơi |

| lỗ khoan mịn | nhiễu loạn tối thiểu, dễ dàng lợn | 25% ít xói mòn, cuộc sống lâu hơn |

| Khả năng tùy chỉnh | Bán kính/góc/lớp phủ phù hợp | Linh hoạt cho các dự án độc đáo |

Những bảng này, được rút ra từ điểm chuẩn của ngành, phục vụ như ngôi sao dẫn đường giữa biển kỹ thuật. Chưa, thước đo thực sự nằm ở lò rèn của chúng ta: Tạo hình được tối ưu hóa bằng AI giúp giảm thiểu khuyết tật <0.1%, 95% tái chế phế liệu phù hợp với mục tiêu không có lưới, và các biến thể tương thích với H2 (mỗi API 5LC mới nổi) chống lại sự thay đổi năng lượng trong tương lai. Những thách thức như làm cứng khí chua? Gặp gỡ với quá trình làm nguội tiên tiến. Đẩy đường kính lớn? Máy ép thủy lực hiện đã đạt 60″. Những lời thì thầm của khách hàng—một cái đuôi lợn vát cho những chiếc cà vạt vùng Vịnh—trở thành tiêu chuẩn chỉ sau một đêm.

trong này 2025 thuận lợi, khi các đường ống phát triển theo hướng năng lượng tái tạo lai, ASTM A860 WPHY 52 và 65 phụ kiện uốn cong kiên quyết: Có hiệu quả, bền bỉ, thiết yếu. Chúng là đường cong nối tham vọng với thành tích. Cho dự án tiếp theo của bạn, hãy cùng nhau uốn cong tương lai.