Long Radius Elbow, Short Radius Elbow, LR & SR Elbow

April 7, 2024

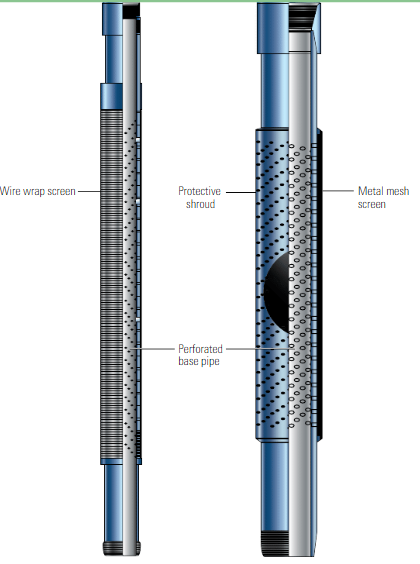

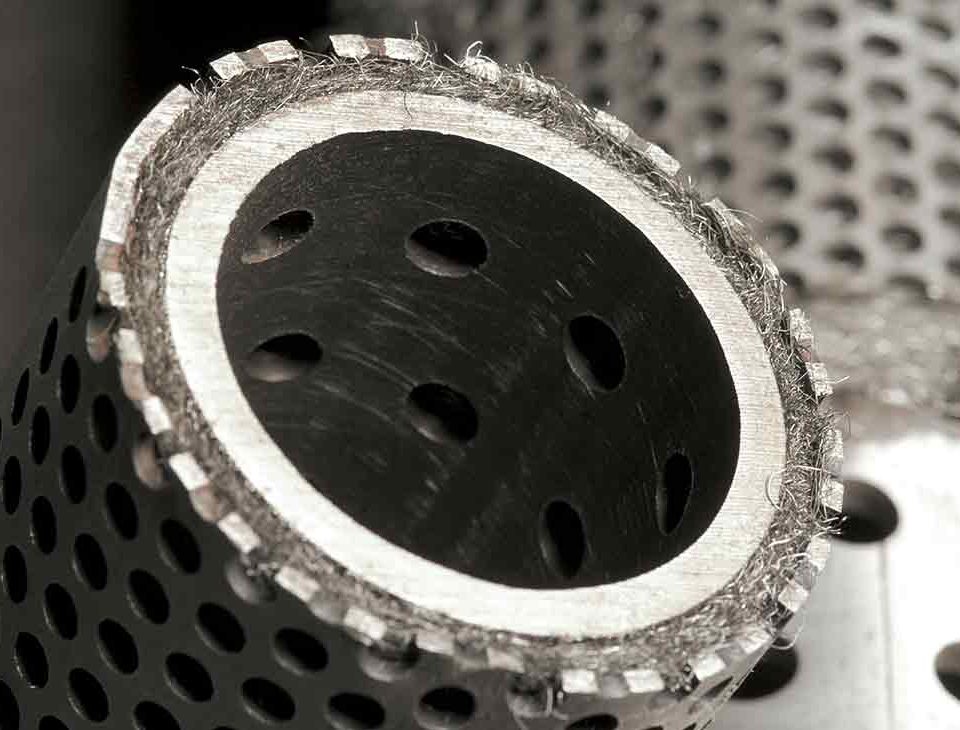

Pipe-Based Sand Control Screen: A Comprehensive Solution for Effective Filtration

April 15, 2024Bridge Slot Screen Pipe: A Versatile Solution for Filtration and Well Completion

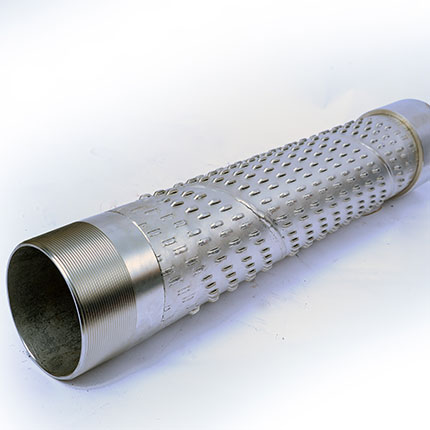

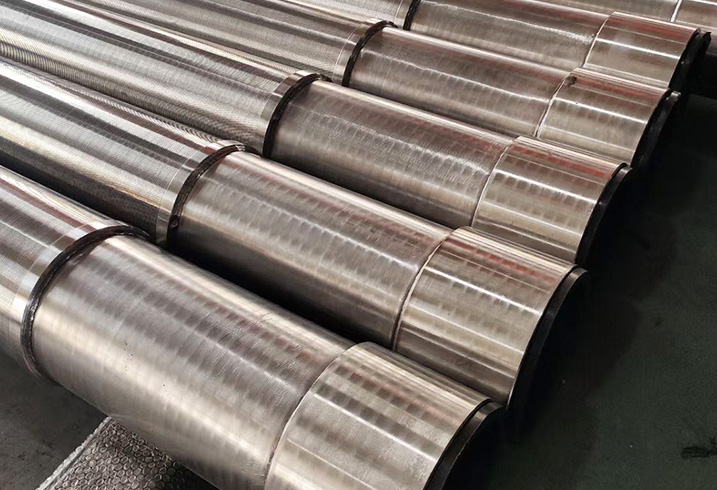

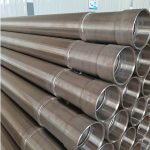

Bridge slot screen Pipes are widely used in the oil and gas industry, as well as in various industrial applications, for filtration and well completion purposes. These screens are designed to provide a reliable and efficient solution for controlling sand, gravel, and other particulate matter in wells and boreholes. Bridge slot screens are available in different materials, with stainless steel (304, 304L, 316, 316L) and low carbon galvanized steel (LCG) being among the most commonly used options.

Introduction to Bridge Slot Screen pipes

Bridge slot screen Pipes, also known as bridge slotted screens or bridge slotted pipe, consist of a series of narrow slots or openings that are cut or formed into a pipe or casing. These slots allow for the passage of fluids while preventing the entry of unwanted particles. The design of bridge slot screens ensures a balance between filtration efficiency and hydraulic capacity, making them suitable for a wide range of applications.

| Diameter (mm) | 146 | 159 | 219 | 273 | 325 | 377 | 426 | 529 | ||||||||||||

| ID | 130 | 140 | 138 | 200 | 198 | 254 | 250 | 246 | 305 | 300 | 297 | 357 | 350 | 346 | 406 | 400 | 398 | 502 | 500 | 498 |

| Thickness | 5 | 5 | 6 | 5 | 6 | 5 | 6 | 8 | 5 | 6 | 8 | 5 | 6 | 8 | 5 | 6 | 8 | 6 | 7 | 8 |

| OD Coupling | 146 | 160 | 162 | 220 | 226 | 274 | 278 | 278 | 325 | 328 | 329 | 377 | 378 | 379 | 426 | 428 | 432 | 529 | 530 | 531 |

| Diameter (mm) | 159 | 219 | 273 | 325 | 377 | 426 | 529 | ||||||||||||

| Wall Thickness | 5 | 6 | 5 | 6 | 5 | 6 | 8 | 5 | 6 | 8 | 5 | 6 | 8 | 5 | 6 | 8 | 6 | 7 | 8 |

| Tensile Strength(KN) | 230 | 270 | 320 | 390 | 400 | 490 | 653 | 480 | 570 | 760 | 560 | 670 | 893 | 630 | 760 | 1048 | 782 | 944 | 1296 |

| Anti Extrusion(N/cm) | 520 | 690 | 340 | 450 | 170 | 230 | 306 | 136 | 203 | 270 | 128 | 183 | 244 | 92 | 135 | 203 | 90 | 136 | 186 |

Material Options for Bridge Slot Screen pipes

- Stainless Steel (304, 304L, 316, 316L):

- Stainless steel bridge slot screens are highly corrosion-resistant, making them ideal for applications where exposure to corrosive fluids or environments is a concern.

- Stainless steel alloys such as 304, 304L, 316, and 316L offer excellent strength and durability, ensuring long-lasting performance.

- These materials are also known for their resistance to high temperatures, making them suitable for use in demanding conditions.

- Low Carbon Galvanized Steel (LCG):

- Low carbon galvanized steel bridge slot screens are coated with a layer of zinc, providing protection against corrosion.

- LCG screens are cost-effective and offer good mechanical strength, making them suitable for various industrial applications.

- The galvanized coating enhances the longevity of the screens, making them resistant to rust and other forms of deterioration.

Applications of Bridge Slot Screen Pipes

Bridge slot screens find applications in a wide range of industries and scenarios. Some common applications include:

- Oil and Gas Industry:

- Bridge slot screens are used in oil and gas wells for sand control and well completion purposes. They prevent the entry of sand and other particulate matter, ensuring the smooth flow of oil and gas.

- These screens also help in stabilizing the formation and preventing damage to the wellbore.

- Water Wells and Boreholes:

- Bridge slot screens are used in water wells and boreholes to filter out sand, gravel, and other debris. They ensure the delivery of clean and sediment-free water.

- Industrial Filtration:

- Bridge slot screens are employed in various industrial filtration applications, including wastewater treatment, chemical processing, mining, and food processing.

- They help in separating solids from liquids, ensuring the quality and purity of the final product.

- Geothermal Wells:

- Bridge slot screens are used in geothermal wells to control the inflow of sand and other particles, preventing clogging and damage to the wellbore.

Advantages of Bridge Slot Screen Pipes

Bridge slot screens offer several advantages over other filtration options:

- High Filtration Efficiency:

- The design of bridge slot screens allows for effective filtration of sand, gravel, and other particulate matter, ensuring the smooth flow of fluids while preventing clogging.

- Versatility:

- Bridge slot screens can be customized to meet specific project requirements, including slot size, pipe diameter, and material selection.

- They can be easily adapted to different well conditions and applications.

- Durability:

- Stainless steel and low carbon galvanized steel are known for their strength and durability, ensuring long service life even in harsh environments.

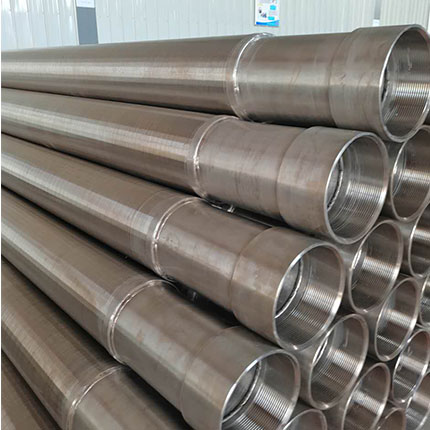

- Easy Installation:

- Bridge slot screens are relatively easy to install, saving time and labor costs during well completion or retrofitting processes.

Conclusion

Bridge slot screens are essential components in the oil and gas industry, as well as in various industrial applications. They provide an efficient solution for sand control, well completion, and industrial filtration. With material options such as stainless steel (304, 304L, 316, 316L) and low carbon galvanized steel (LCG), bridge slot screens offer corrosion resistance, durability, and versatility.

When selecting bridge slot screens, it is important to consider the specific requirements of the application, such as the desired slot size, pipe diameter, and material compatibility. Consulting with industry experts or reputable suppliers can help ensure the proper selection and installation of bridge slot screens for optimal performance and longevity.