Quality in Turning of Inconel X-750 Superalloy Steel Pipe

January 14, 2025

What is super stainless steel? Nickel-based alloy?

February 18, 2025Outline: Gravel Pack Screen Pipe

| Section | Subtopics |

|---|---|

| Introduction | Overview of Gravel Pack Screen Pipes, Importance in Sand Control, and Applications |

| What are Gravel Pack Screen Pipes? | Definition, Design, and Function of Gravel Pack Screen Pipes |

| Key Features of Gravel Pack Screen Pipes | V-shaped Wire, Self-Cleaning Properties, Enhanced Flow, and Collapse Resistance |

| Benefits of Gravel Pack Screen Pipes | Sand Control, Improved Well Life, Filtration Capacity, and Efficient Operations |

| Applications of Gravel Pack Screen Pipes | Oil and Water Extraction, Sand Control in Various Industries |

| Materials and Construction | Stainless Steel and Carbon Steel, Wire Sizes, Based Pipe Holes, Support Rods, and End Connections |

| Design of Gravel Pack Screen Pipes | Multi-layer Screens, Shunt Tube Systems, Flow Redirection, and Gravel Packing Solutions |

| Prepacked Screens | When Prepacking is Feasible, Design of Prepacked Gravel Packing Screens |

| Product Specifications | Screen Parameters, Material Types, Hole Sizes, Wire Specifications, and Support Rod Information |

| Performance Features | Collapse Resistance, Filtration Efficiency, Enhanced Low Profile Design |

| Gravel Packing Technology | Sand Control Technology Under the Well, Related Services and Solutions |

| Certifications | ISO, CE, SGS Certifications for Quality Control |

| Maintenance and Care | Proper Handling, Inspection, and Maintenance of Gravel Pack Screen Pipes |

| Comparison with Other Sand Control Methods | Gravel Packing vs. Other Techniques (Slotted Liners, Wire-wrapped screens) |

| Challenges in Gravel Packing Operations | Common Issues and Solutions, Prevention of Obstructions, Handling Slurry during Gravel-Pack Operations |

| Conclusion | Summary of Gravel Pack Screen Pipe Benefits and Considerations |

What are Gravel Pack Screen Pipes?

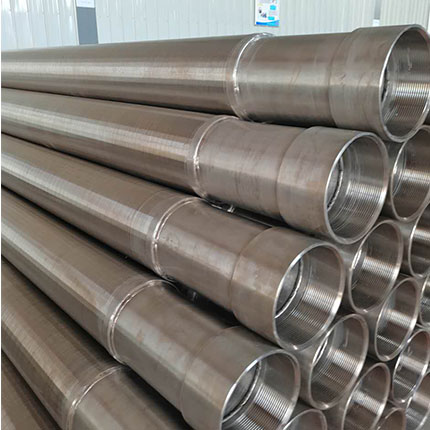

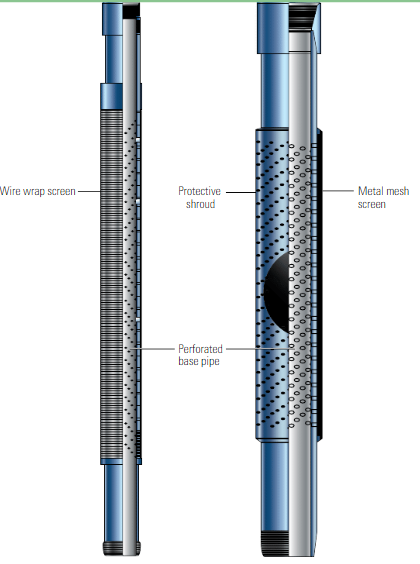

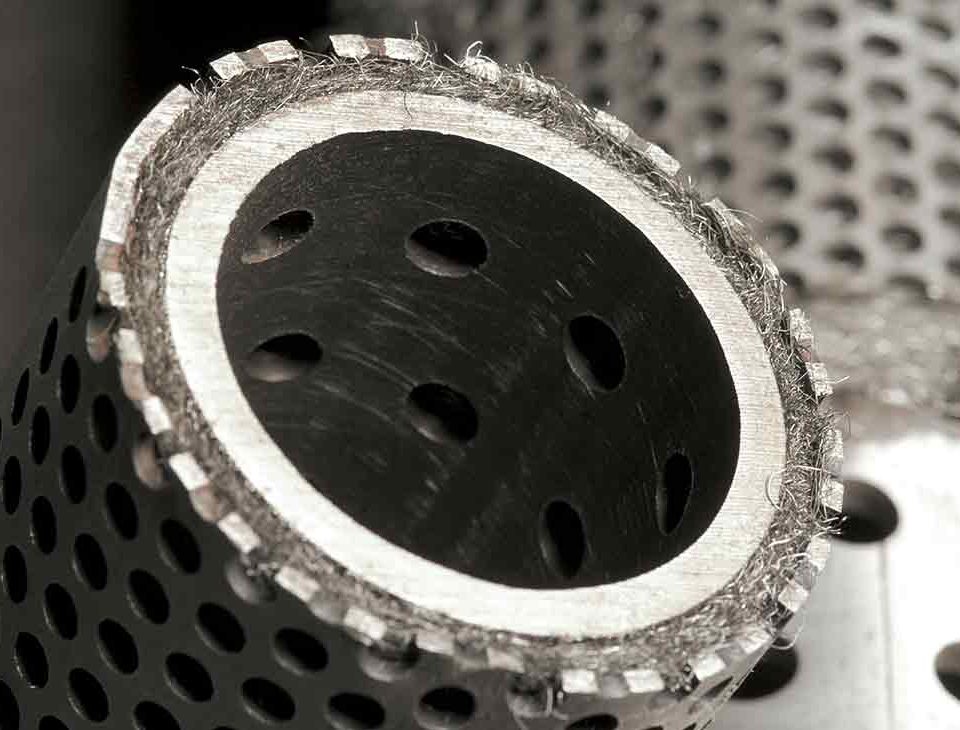

Gravel pack screen pipes are essential for controlling the movement of sand and other particles in a well, especially in oil and water extraction operations. The screens are constructed using a base pipe surrounded by a series of tightly wound wires that form the filtering mechanism. These pipes are generally used in gravel packing, a technique employed to enhance well productivity by preventing sand production while allowing the free flow of oil or water.

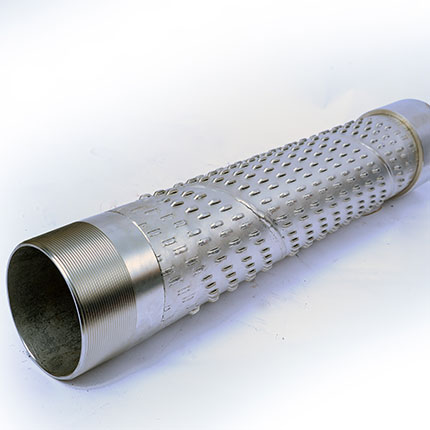

The gravel pack screen pipe’s key feature is the V-shaped wire geometry, which creates a keystone-shaped structure that ensures self-cleaning properties. This minimizes the risk of clogging and helps maintain consistent performance during operation. The wire wrapping on the screen significantly improves the open area when compared to traditional slotted liners, resulting in higher filtration capacity and longer well life.

Product Parameters for Gravel Pack Screen Pipes:

| Parameter | Specification |

|---|---|

| Material | Stainless Steel, Carbon Steel |

| Hole Size of Base Pipe | 16mm – 30mm (customizable based on requirements) |

| Support Rod Sizes | 2.23.5mm, 35mm, 3.26mm, 47mm |

| Wire Sizes | 2.23.5mm, 35mm, 3.26mm, 47mm |

| End Connection | Male/Female Thread, Flange, Welded Ring |

| Certification | ISO, CE, SGS |

| Pipe Type | Wire-Wrapped, Multi-layer (as required) |

| Gravel Packing | Prepacked or Conventional Gravel Packing (as applicable) |

| Design | V-shaped Wire for Self-cleaning, Enhanced Filtration |

| Collapse Resistance | Designed with multiple ribs for enhanced collapse resistance |

| Operating Conditions | Suitable for Oil, Gas, and Water Extraction Wells |

| Prepacked Screen Design | Available for when gravel packing is not feasible |

Key Features of Gravel Pack Screen Pipes

V-Shaped Wire Design

The unique V-shaped wire design of the gravel pack screen pipe creates a keystone structure, ensuring high efficiency in sand control. This design is beneficial for self-cleaning, as it reduces the likelihood of clogging. The gap between the wires allows finer particles to be filtered out while maintaining a consistent flow of oil or water.

Self-Cleaning Performance

The V-shaped wire not only prevents clogging but also promotes self-cleaning properties. As the fluid passes through the screen, the shape of the wires ensures that any particles or debris are easily removed, thus maintaining the screen’s performance.

External Force Transfer

External forces that occur during well operations are directly transferred to the base pipe, which prevents damage to the gravel pack screen structure and enhances its durability.

Collapse Resistance

Gravel pack screens are designed with multiple ribs that ensure collapse resistance under high-pressure conditions. This feature ensures that the pipe will maintain its shape and structural integrity, even in extreme environments.

Benefits of Gravel Pack Screen Pipes

Sand Control

Gravel pack screen pipes are highly effective in controlling sand production, which can damage well equipment and reduce the overall lifespan of the well. By preventing sand from entering the system, these pipes significantly improve well longevity.

Improved Well Life

With gravel pack screen pipes, the well life is extended due to the high filtration capacity and collapse resistance of the pipes. The ability to effectively filter out fine particles and sand contributes to a more sustainable and efficient well operation.

Filtration Capacity

The use of gravel pack screens increases the filtration capacity of the well. The wire-wrapped screen design offers up to ten times more open area than traditional slotted liners, which allows for better gravel distribution and more efficient filtration.

Efficient Operations

Gravel pack screens ensure that well operations are carried out more efficiently, with reduced downtime due to clogging or maintenance issues. The design of these screens helps maintain a continuous flow of fluid, reducing the chances of blockages or system failures.

Applications of Gravel Pack Screen Pipes

Gravel pack screen pipes are most commonly used in the following applications:

- Oil and Gas Extraction: These pipes are crucial in preventing sand production in oil and gas wells, thus ensuring that extraction is efficient and damage-free.

- Water Extraction: Gravel pack screens are used in water wells to prevent sand from contaminating the extracted water and to improve the overall efficiency of water retrieval.

- Chemical and Mining Industries: Gravel packing is also employed in mining and chemical extraction operations to prevent clogging and improve material flow.

Materials and Construction

Materials

Gravel pack screen pipes are primarily constructed from stainless steel and carbon steel, both of which offer excellent durability and resistance to corrosion.

Wire Sizes and Based Pipe Holes

The wire sizes typically range from 2.2mm to 7mm, with the size depending on the specific application requirements. The holes in the base pipe can range from 16mm to 30mm.

Support Rods

The support rods used in the construction of gravel pack screens can be customized according to specific needs, with sizes ranging from 2.2mm x 3.5mm to 4mm x 7mm.

End Connections

Gravel pack screen pipes are equipped with various end connections, including male/female threads, flanges, and welded rings, allowing for easy integration into well systems.

Prepacked Screens

In some cases, prepacked screens are used when gravel packing is not feasible. These screens provide built-in sand control and can be used as a permanent solution for filtration. Prepacked screens incorporate keystone-shaped wire for both the inner and outer wraps, ensuring reliable performance over time.

Certifications

Gravel pack screen pipes are manufactured to meet international quality standards and come with the following certifications:

- ISO: International Organization for Standardization.

- CE: Conformité Européene (European Conformity).

- SGS: Société Générale de Surveillance for quality assurance.

Maintenance and Care

Proper maintenance is essential for maximizing the lifespan and efficiency of gravel pack screen pipes. Routine inspections should be conducted to ensure there are no obstructions or wear-and-tear issues. When well operations are completed or if a screen is blocked, thorough cleaning or replacement may be required.

Comparison with Other Sand Control Methods

While gravel pack screen pipes are one of the most advanced sand control technologies, they can be compared to other techniques, such as:

- Slotted Liners: Slotted liners are often less efficient at controlling sand, as they have larger gaps and can lead to greater clogging.

- Wire-Wrapped Screens: These screens offer higher filtration capacity compared to slotted liners, with gravel pack screens offering even better performance.

Challenges in Gravel Packing Operations

Although gravel pack screen pipes are highly effective, challenges can arise during well operations. Issues like premature bridging of the slurry or obstructions during gravel-pack operations can cause flow issues. The use of advanced shunt tube systems helps redirect flow through sections that are blocked or bridged, ensuring uniform gravel distribution.

Gravel pack screen pipes offer a reliable solution for sand control and filtration in oil, gas, and water extraction industries. Their advanced design, robust construction, and high filtration capacity ensure that these pipes provide efficient performance and extended well life. Understanding the features, materials, and applications of gravel pack screen pipes can help operators choose the best solution for their specific needs.