Bridge Slot Screen Pipe: A Versatile Solution for Filtration and Well Completion

April 11, 2024

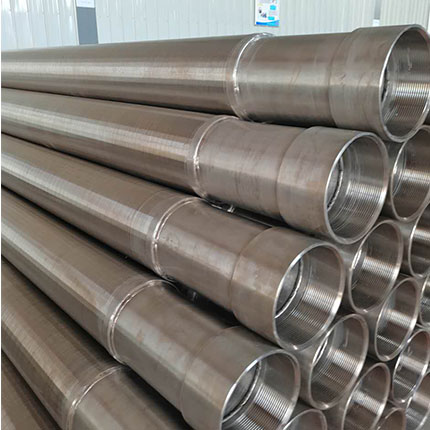

Slot liner , Slotted Liner Pipe

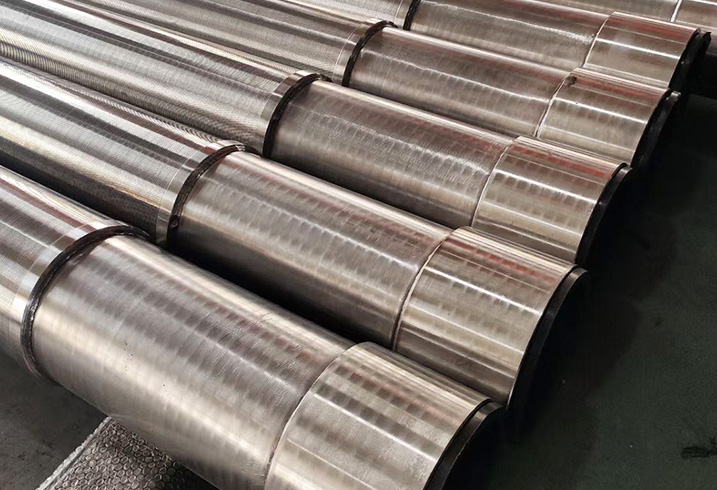

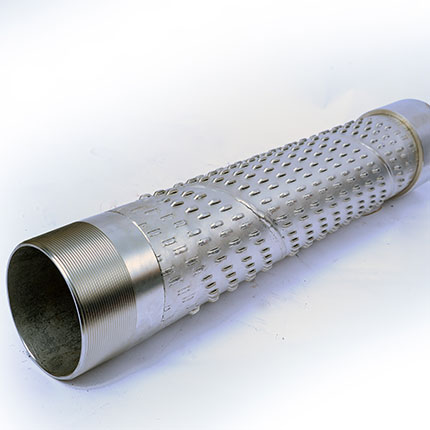

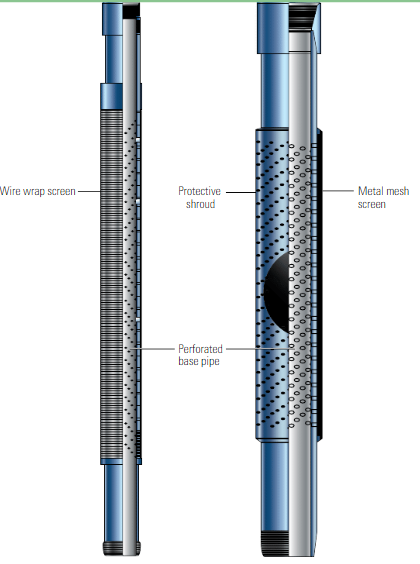

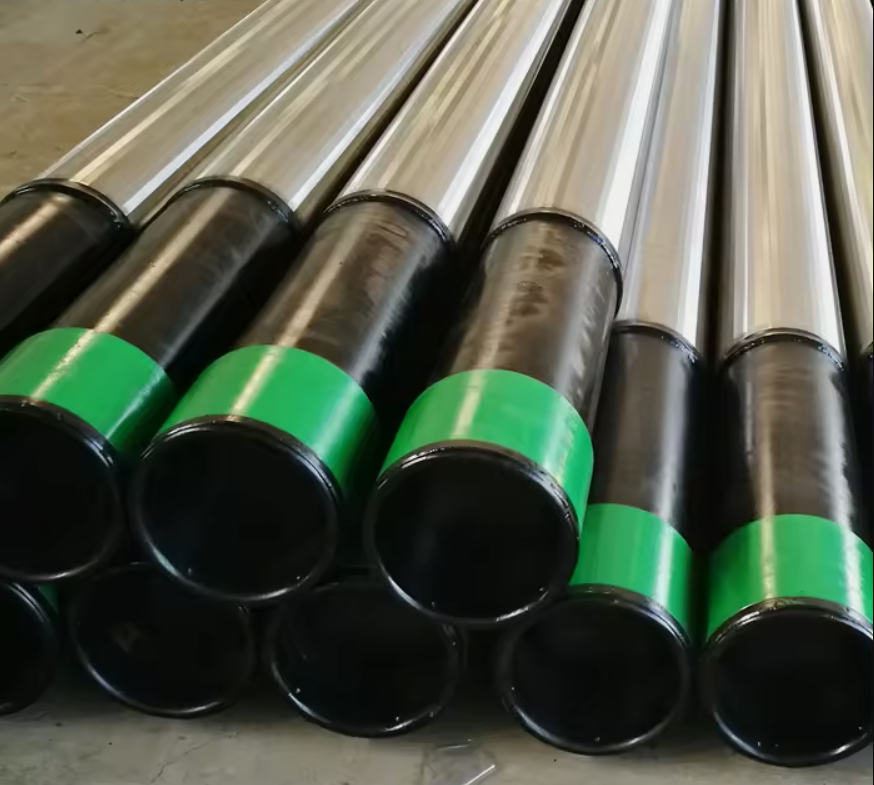

April 19, 2024Pipe-based sand control screens are essential components used in oil and gas wells, as well as in various industrial applications, to prevent the influx of sand and other particulate matter. These screens are designed with slots of varying sizes and are available in different materials such as low-carbon steel, medium carbon steel, and stainless steel (201, 304, 304L, 316, 316L, duplex stainless steel, 2205, 2207). With customizable length, outer diameter, wedge wire specifications, and end connections, pipe-based sand control screens offer versatility and efficiency in sand control operations.

Introduction to Pipe-Based Sand Control Screens

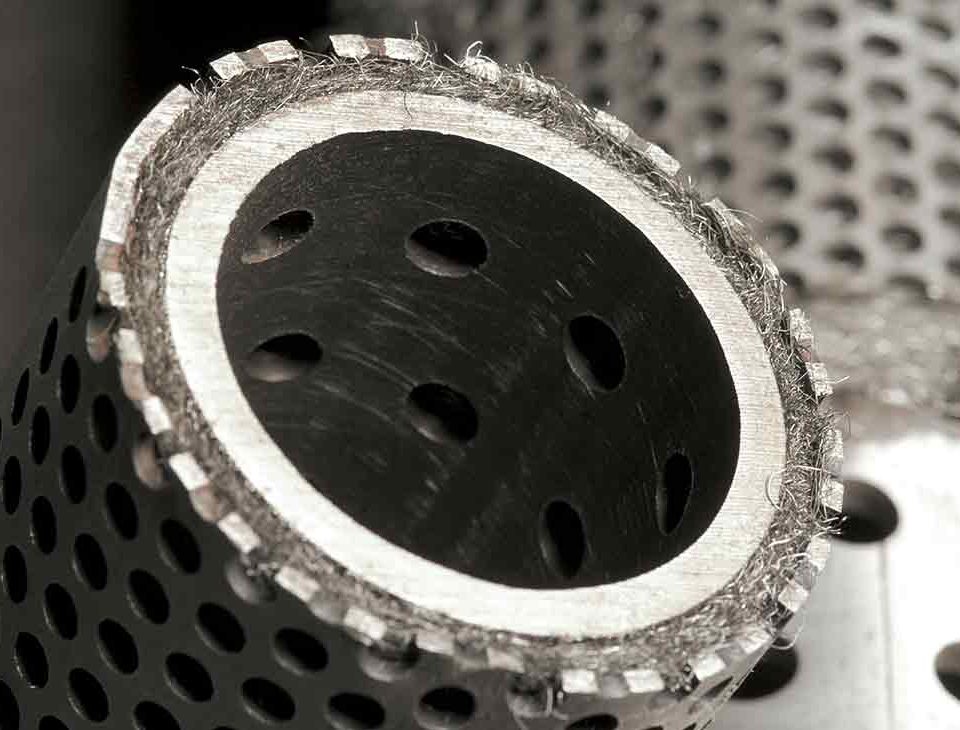

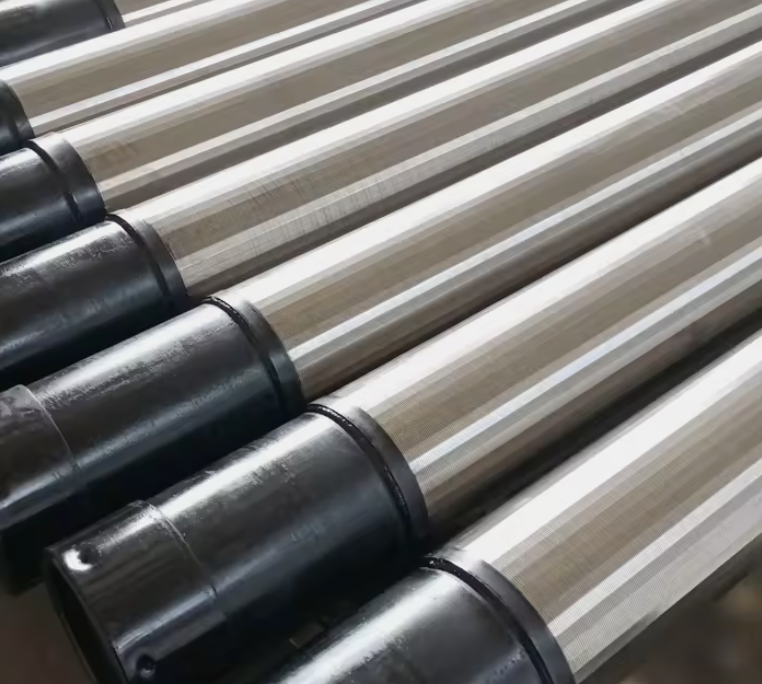

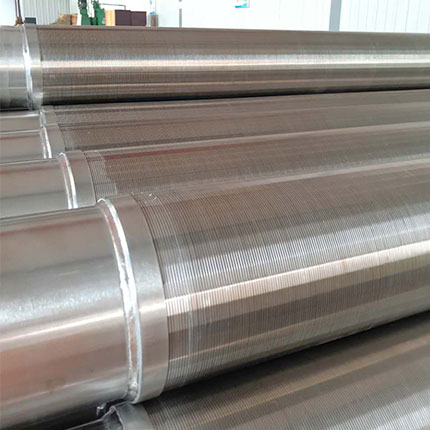

Pipe-based sand control screens, also known as wire-wrapped screens or wire-wound screens, consist of a perforated pipe wrapped with a continuous wedge wire or V-shaped wire. The slots or openings in the screen allow for the passage of fluids while preventing the entry of sand and other particles. The design of pipe-based screens ensures optimal sand control while maintaining high flow rates and minimizing pressure drop.

| Wedge Wire |   |

|

|

|

|

|

|

|

| Width(mm) | 0.75 | 1 | 1.5 | 2 | 2.3 | 3 | 3.5 | 4 |

| Height(mm) | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6.5 | 8 |

| Support Rod Shape |    Or Or |

|

||||||

| Width(mm) | 2 | 2.3 | 3 | 4 | 5 | Φ2.5-Φ5 | ||

| Height(mm) | 3 | 3 | 4.8 | 6 | 8 | |||

| Remarks | Customize as clients’ requests | |||||||

Key Features of Pipe-Based Sand Control Screens

- Slot Size:

- Pipe-based sand control screens offer a wide range of slot sizes, ranging from 0.05mm to 20mm. The slot size is selected based on the specific application requirements, ensuring effective sand control while allowing for the desired flow rate.

- Material Options:

- Pipe-based sand control screens are available in various materials to suit different operating conditions. Options include low-carbon steel, medium carbon steel, and stainless steel alloys such as 201, 304, 304L, 316, 316L, duplex stainless steel, 2205, and 2207. The material selection depends on factors such as corrosion resistance, strength, and compatibility with the well fluids.

- Length and Outer Diameter:

- Pipe-based sand control screens can be customized in terms of length and outer diameter to fit specific wellbore dimensions and operational requirements. The length can range from 30mm to 6000mm, while the outer diameter can vary from 114mm to 600mm.

- Wedge Wire Specifications:

- The wedge wire, or V-shaped wire, used in pipe-based sand control screens is available in different specifications. Common options include 0.75X1.5mm, 1X2mm, 1.5X2.5mm, 2X3mm, 2.3X4mm, 3X5mm, and 3.5X6.5mm. The selection of wedge wire specifications depends on the desired filtration efficiency and sand control requirements.

- End Connections:

- Pipe-based sand control screens can be manufactured with various end connections to facilitate installation and connection to the wellbore. Options include plain beveled ends, flanged couplings, and threaded couplings. The choice of end connection depends on the specific well completion method and operational preferences.

Applications of Pipe-Based Sand Control Screens

Pipe-based sand control screens find applications in a wide range of industries and scenarios. Some common applications include:

- Oil and Gas Wells:

- Pipe-based sand control screens are extensively used in oil and gas wells to prevent sand production and ensure the smooth flow of hydrocarbons. They help in maintaining well integrity and protecting downhole equipment.

- Water Wells and Boreholes:

- Pipe-based sand control screens are employed in water wells and boreholes to filter out sand, gravel, and other particulate matter. They ensure the delivery of clean and sediment-free water.

- Geothermal Wells:

- Pipe-based sand control screens are used in geothermal wells to control sand and prevent clogging of the wellbore. They help in maintaining the efficiency and longevity of the geothermal system.

- Industrial Filtration:

- Pipe-based sand control screens are utilized in various industrial filtration applications, including wastewater treatment, chemical processing, mining, and food processing. They help in separating solids from liquids, ensuring the quality and purity of the final product.

Advantages of Pipe-Based Sand Control Screens

Pipe-based sand control screens offer several advantages over other sand control methods:

- Effective Sand Control:

- The design of pipe-based screens with precise slot sizes ensures efficient sand control, preventing the entry of sand and other particulate matter while allowing for the smooth flow of fluids.

- High Flow Capacity:

- Pipe-based sand control screens provide high flow capacity, minimizing pressure drop and maintaining optimal production rates.

- Customizable Design:

- The customizable features of pipe-based sand control screens, such as slot size, length, outer diameter, wedge wire specifications, and end connections, allow for tailored solutions to meet specific project requirements.

- Corrosion Resistance:

- Stainless steel options, suchas 304, 304L, 316, and 316L, offer excellent corrosion resistance, ensuring the longevity and durability of the sand control screens in harsh operating environments.

- Versatility:

- Pipe-based sand control screens can be used in a wide range of applications, including oil and gas wells, water wells, geothermal wells, and industrial filtration systems. Their versatility makes them a reliable choice for various industries.

- .

Frequently Asked Questions (FAQ)

1. What is the purpose of using pipe-based sand control screens?

Pipe-based sand control screens are used to prevent the influx of sand and other particulate matter in oil and gas wells, water wells, geothermal wells, and industrial filtration systems. They ensure the smooth flow of fluids while maintaining optimal sand control.

2. How are the slot sizes of pipe-based sand control screens determined?

The slot sizes of pipe-based sand control screens are selected based on the specific application requirements. Factors such as the size of the sand particles, desired flow rate, and well conditions are taken into consideration to determine the appropriate slot size.

3. Can pipe-based sand control screens be customized to fit specific wellbore dimensions?

Yes, pipe-based sand control screens can be customized in terms of length and outer diameter to fit specific wellbore dimensions and operational requirements. This ensures a perfect fit and optimal sand control.

4. What are the advantages of using stainless steel pipe-based sand control screens?

Stainless steel pipe-based sand control screens, such as those made from 304, 304L, 316, and 316L alloys, offer excellent corrosion resistance. They are highly durable and can withstand harsh operating conditions, making them ideal for long-term use.

5. In which industries are pipe-based sand control screens commonly used?

Pipe-based sand control screens find applications in various industries, including oil and gas, water supply, geothermal energy, and industrial filtration. They are used in wells, boreholes, and filtration systems to ensure efficient sand control and the delivery of clean fluids.

Pipe-based sand control screens provide a comprehensive solution for effective sand control in various industries. With their customizable features, including slot size, length, outer diameter, wedge wire specifications, and end connections, these screens offer versatility and efficiency. Whether it’s oil and gas wells, water wells, geothermal wells, or industrial filtration systems, pipe-based sand control screens play a crucial role in maintaining optimal production rates and protecting equipment from sand ingress. By choosing the right materials and design specifications, operators can ensure long-lasting sand control and reliable well performance.