Evergreen Steel company Want buy Cold rolled EN10219 S355JOH seamless pipe

August 31, 2022

API2H LSAW PIPE 5728 MTONS for AYBI STEEL

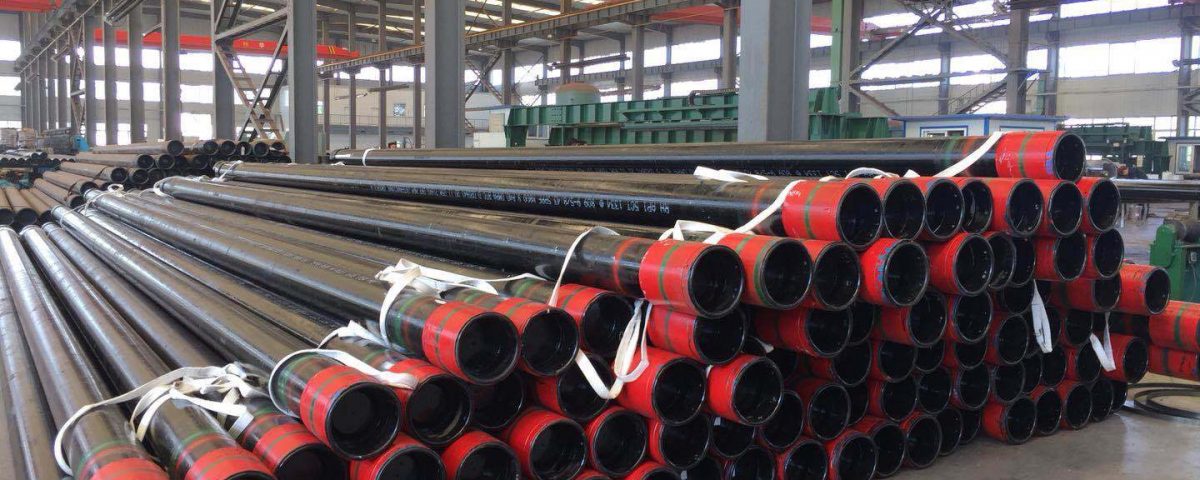

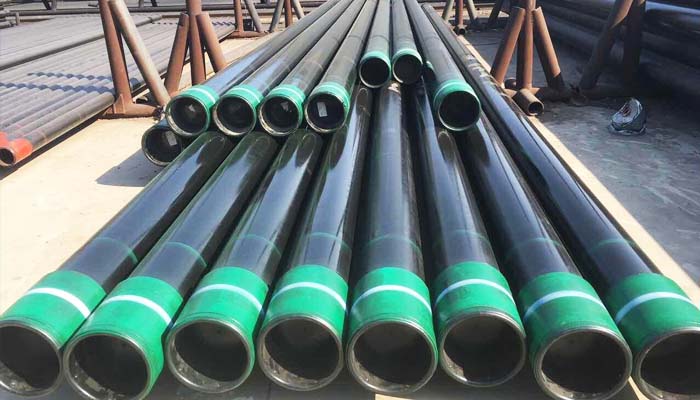

September 5, 2022KERUI GROUP Inquiry for L80 tubing with internal protective coating

1. NAME AND APPLICATION FIELD

1.1. Name — tubing with internal protective coating.

1.2. Application Field – tubing with internal protective coating has been widely used over the globe for more than 60 years. The polymer coating of the tubing inner surface protects it from general corrosion, CO2 and H2S-corrosion, caused by sulfur reducing bacteria, prevents from deposits of asphalts and scale build-up, improves the hydraulic proper

Brief characteristics of Aban, West Paydar field product content and production horizon

|

Seq. No. |

Name |

Unit of meas. |

Value |

|

1 |

Occurrence depth |

m |

3000-4000 |

|

2 |

Formation pressure |

kg/cm2 |

Up to 320 |

|

3 |

Formation temperature |

°С |

113 |

|

4 |

Н2S content in formation gas |

Molar concentration, 5 |

< 0.64 |

|

5 |

СО2 content in formation gas |

Molar concentration, 5 |

< 2.74 |

|

6 |

Paraffin content in formation fluids |

Weight content, % |

< 3% |

- TECHNICAL REQUIREMENTS.

|

No. |

Requirements /parameters |

TUBING |

|

1 |

General requirements |

1. The seamless tubing and couplings with the DN 3-1/2” OD, weight per unit length 9,2 lb/ft and with the wall thickness of 6.45mm must meet the requirements of API 5CT. 2. The seamless tubing and couplings with the DN 4-1/2” OD, weight per unit length 12,75 lb/ft and with the wall thickness of 6.88 mm must meet the requirements of API 5CT. |

|

2 |

Characteristics of the oilfield environment and operating conditions |

Pumped medium – multiphase medium, consisting of oil, gas (free and solved in the liquid medium), water and contamination, with the following properties: Average temperature under formation conditions – 40-150 °С; oil density – 750-1000 kg/m3; water density – 1000-1200 kg/m3; Н2О weight content up to 50%; Н2S content – up to 1.0% molar and CO2 content – up to 2.5% molar, impurities from 100 to 1000 mg/l, Paraffin content – up to 36% of mass. Ambient temperature from 0 to +60 ° С |

More efficient in oil & gas extraction Page 2 of 8

|

3 |

Tubing production method |

Seamless |

|

4 |

Manufacturers’ warranty |

Tubing manufacturers’ warranty: Number of RIH/POOH operations with a phosphated coupling – 6 RIH/POOH, with galvanized coupling – 10 RIH/POOH operations; working service — 18 months TSN or 24 months from the delivery time whichever falls first. |

|

5 |

The service life shall be calculated as follows: |

60 months |

|

6 |

Level of requirements to the product |

According to Table H.1 API 5CT for tubing L80 Type 13Cr, with the mandatory SSC test, in accordance with API 5CT. |

|

7 |

Requirements to the length of tubing |

Interval 2 (28-32 feet), permissible length deviation, max. 2.0. |

|

8 |

Requirement to the wall thickness |

The wall thickness shall be measured and registered along the entire length to provide evidence of compliance of the wall thickness with the requirements of API 5CT standard. For the surface, covered by automated control system, the minimum coverage shall be 25%. |

|

9 |

Chemical make-up of tubing and coupling steel |

The chemical properties shall be adopted in accordance with the requirements of Table C.4 API 5CT for steel of the strength group L80 Type 13Cr; |

|

10 |

Mechanical properties |

The mechanical properties shall be adopted in accordance with the requirements of Table C.5 API 5CT for steel of the strength group L80 Type 13Cr; |

|

11 |

Heat Treatment |

According to API 5CT, production process is -S. C- heat treatment along the entire length is mandatory. Normalized or normalized and annealed, at manufacturer’s option. |

|

12 |

Impact-Bending Test |

Charpy V-notched Impact Test. The impact test shall be in accordance with Appendix А.10 SR16. The test temperature shall be 21°C (70°F) for the grade J55 and К55 and 0°C (32°F) for rest of the groups; upon Agreement between the Buyer and the Manufacturer lower temperature is also possible. |

|

13 |

NDT |

All the tubes shall undergo tests for detection of the transverse and longitudinal defects on the outer and inner surfaces with the Ultrasonic Level 3 or EMI in accordance with the requirements of А.2 SR1. |

|

14 |

Nipple and coupling threads |

Type of threaded connection – Coupling, (NU), Buttress (according to API Spec 5B) The external thread of the product shall undergo abrasive flow machining by any relevant method, including the thread machining process agreed between the Buyer and the Manufacturer as appropriate to exclude the material with scoring and flaking susceptibility during cross-threading. |

|

15 |

Requirement to the production of couplings |

The couplings shall be seamless, of the same grade and type as the tubes, shall meet the same PSL level of requirements or higher and shall undergo the same thermal treatment as the tubes. |

|

16 |

Requirements to the surface of tubes and couplings |

The couplings shall be free of deficiencies leading to the thread discontinuity |

More efficient in oil & gas extraction Page 3 of 8

|

17 |

Hydrostatic test |

Time for holding the tubing under the internal test pressure shall not exceed of 10 seconds, pressure drops are not allowed. |

|

18 |

Coating |

The tubing shall have any type of outer coating preventing them from corrosion during their transport and storage within 6 months. |

|

19 |

Greasing of nipple and coupling threads |

According to the Agreement between the Manufacturer and the Buyer the grease can be applied both the to the tubing and coupling. Unless otherwise stated in the Agreement, the grease shall meet the requirements of ISO 13678 or API RP 5A3. Tubing with threads and couplings shall have thread protectors on their free ends and couplings. Tubing with threaded ends but without couplings shall have thread protectors on both ends. |

|

20 |

Tubing marking |

Each tube shall have clear punch or milling marking applied at a distance of 0.9mm from free coupling faces with the hight of characters 5-8mm, depth 0.25-0.4mm (ensured by the procedure, not controlled) indicating the following information: – DN*wall thickness, mm – grade – owner identifying name (ZN Vostok LLC) – manufacturer’s identifying name or trademark- tube number- tube length, cm- manufacture date (month, year). Each tube shall have clear marking applied longitudinally with a light paint, with the hight of the characters 20-50mm, indicating the following information: – tube bank number- tube number- DN, mm- wall thickness, mm; The numbers of banks and tubes shall not repeat within a calendar year. |

|

21 |

Coupling marking |

The coupling shall have punch or milling marking (Appendix 1) indicating the following information: – grade – manufacturer’s identifying name or trademark – manufacture date (month, year), hight of characters 5-8 mm, depth of characters 0.25- 0.4mm |

|

22 |

Packaging, transport and storage |

It is necessary to ensure packing of tubes in hexagonal packages, delivery of new tubes with transport straps or textile slings on the nipple or coupling face of the tube bank designed for lifting the rube banks and approaching steel slings, the length of the transport straps shall prevent simultaneous hooking. The couplings of the tubes in the bank shall be located on the same side. There shall be a information tag securely fastened on both sides of tube banks to protect its loss during transportation. The field ends shall be covered with shipping bonnet to protect them from mechanical damages. The packaging shall be nonreturnable. |

More efficient in oil & gas extraction Page 4 of 8

|

23 |

Information tag |

Shall contain the following information: – order number – manufacturer’s identifying name or trademark – diameter and wall thickness, mm – grade – joint design – batch number – number of the tube bank (individual for each bank) – the range of the tube numbers in the bank as per quality certificate – number of tubes in the bank – total length in meters of tubing in the bank, m – net weight, gross weight, kg – manufacture date (month, year). The information shall be clear and easy to read. |

|

24 |

Incoming Inspection |

The Customer is entitled to require tubing manufacturing inspection and incoming inspection by an independent inspection company. |

|

25 |

Quality Certificate |

Shall contain the following information: – order number – information on exporter and receiver – manufacturer’s identifying name or trademark – diameter and wall thickness, mm – grade – type of threaded connection – heat numbers, batch numbers – type of coating (internal, outer), if any – – number of the tube bank (individual for each bank) and the range of the tube numbers in the bank as per quality certificate – mechanical properties and type of thermal treatment – steel grade and chemical make-up of the steel – thread-sealing grease grade – total number of tubes and information on tube number in each bank – total length in meters of tubing and information on total length in meters in each bank, m – total weight and weight of each bank, kg – manufacture date, quality control results. The Quality Certificate shall be submitted to the Customer in paper form, electronic copy shall be submitted upon request as well. Upon request a Register of tube numbers indicating the length of tubes shall be additionally attached to the Quality Certificate. The Register of tube numbers shall be submitted in the electronic form only. The e-mail shall be indicated in the Tubing Order Form. |

|

26 |

Other requirements |

Shall correspond to API 5CT |

|

Requirements to the internal coating |

||

More efficient in oil & gas extraction Page 5 of 8

|

1 |

Designation |

Protection of the tubing from corrosion attack, contamination, prevention from deposits of asphalts on the tubing inner surface. |

|

2 |

Type of coating |

Advanced polymeric coatings, the tube couplings have thermo-diffusion zinc coating. |

|

3 |

Streamers |

Complete with streamers – corrosion-resistant and thermal-resistant inserts for the protection of the inner surface of a coupling and tube nipple face, an adjusting wrench shall also be included. |

|

4 |

The initial appearance of the tubing internal coating shall meet the following requirements: |

Solid, uniform, flowed glossy surface (ripple markings are allowed in accordance with the profile of the tubing internal coating within possible variation per total length); cracks, pinholes, bubbles and other defects of the surface, uncovering the metal and visible with the naked eye are not permitted. Safe-keeping and integrity of the covering during transportation and storage at temperatures up to -60°С Safe-keeping and integrity of the covering during the tube service within the temperature range from 0 to + 180 °С |

|

5 |

The appearance of the tube internal coating after heating to 260˚С and cooling to 18-25˚С |

Shall meet the following requirements – lack of cracks, visible with the naked eye. |

|

6 |

Appearance of the internal coating after the kickback of 4.5J |

Shall meet the following requirements – lack of chips and cracks down to a metal surface |

|

7 |

Initial dielectric continuity of the internal coating |

Not less than 2.0 kV/mm |

|

8 |

Internal coating of tube ends |

Shall be applied to a steel backplate with a removed layer of a cover metal with depth of 60-80µm at a distance exceeding the length of the tubing thread 2.1-2.3 times. |

|

9 |

Thickness |

Not less than 200 µm |

|

10 |

Density |

2.3 – 2.6 g/cm³ |

|

11 |

Make-up torque |

Shall endure without coat damage not less than the calculated makeup torque |

|

12 |

Hardness by Mohs scale |

not less than 5 |

|

13 |

Tensile strength |

not less than 100 MPa |

|

14 |

impact toughness |

not less than 2.0 J |

|

15 |

Initial adhesion strength against the tubing steel |

Not less than 10.0 MPa |

DATASHEET

More efficient in oil & gas extraction Page 6 of 8

Эскиз муфты

Диаметр НКТ , мм (D) 88,9 Толщина стенки трубы, мм (t) 6,45 Внутренний диаметр трубы трубы (d) 76

Ширина торцовой плоскости муфты с обычной фаской, мм (B) 4,76 Диаметр фаски в торцовой плоскости муфты, мм (d0) 90,5 Диаметр муфт НКТ , мм (Dм) 107,95 Длина муфт НКТ,мм (Lм) 142,88

|

No. |

Name |

Options |

|

1 |

Tubing diameter (outer) |

88.9 mm |

|

2 |

Wall thickness |

6.45 mm |

|

3 |

Grade |

L80 Type 13Cr |

|

4 |

Type of threaded connection |

Coupling,(NU),Buttress (according to API Spec 5B) |

Эскиз муфты

Диаметр НКТ , мм (D) 114,3 Толщина стенки трубы, мм (t) 6,88 Внутренний диаметр трубы трубы (d) 100,54 Ширина торцовой плоскости муфты с обычной фаской, мм (B) 4,76 Диаметр фаски в торцовой плоскости муфты, мм (d0) 115,9 Диаметр муфт НКТ , мм (Dм) 132,08 Длина муфт НКТ,мм (Lм) 155,58

|

No. |

Name |

Options |

|

1 |

Tubing diameter (outer) |

114,3 mm |

|

2 |

Wall thickness |

6,88 mm |

|

3 |

Grade |

L80 Type 13Cr |

|

4 |

Type of threaded connection |

Coupling,(NU),Buttress (according to API Spec 5B) |

More efficient in oil & gas extraction Page 7 of 8

Specifications.

|

N o. |

Name |

Type, Grade, Drawing No, GOST, TS |

Brief Description And Specificatio ns |

Unit Of Meas . |

Volume (Numbe r) |

Price Per Tone, net of VAT, USD |

Total Price, net of VAT, USD |

Price Per Tone, inc. VAT, USD |

Total Price, inc. VAT, USD |

Delivery Time (month, year) |

Venue for delivery of goods, provision of work and services |

Country Of Origin |

|

1 |

Tubing string 3-1/2” L80 Type 13Cr |

API Spec 5B |

Utilized in oil field wells for transportation of gas and liquid substances |

Tons / m |

77,3 / 5 670 |

Regards,

General Director Pervushin VadimMore efficient in oil & gas extraction Page 8 of 8